Dec . 17, 2024 08:43 Back to list

gauge c

Understanding Gauge C A Key Concept in Measurement

In various fields ranging from engineering to manufacturing, the term gauge is of paramount importance. Specifically, gauge C refers to a particular measurement standard that can often be seen in contexts such as wire thickness, sheet metal, and various types of manufacturing processes. Understanding gauge C not only helps in selecting the right materials but also ensures that products meet the required specifications and standards.

What is Gauge?

The term gauge is derived from the Old French word jauge, meaning to measure. It refers to a standard of measuring, particularly used in the context of specifying the thickness of materials. Different industries utilize different gauge systems. For example, in the wire industry, a lower gauge number corresponds to a thicker wire, while a higher gauge number indicates a thinner one. This inverse relationship can be confusing for newcomers, but it is an essential aspect of material selection and application.

Gauge C in Wire Measurement

When discussing wire measurements, gauge C comes into play within the standardized wire gauge (SWG) system, primarily used in the United Kingdom and some Commonwealth countries. In this context, gauge C corresponds to a specific thickness of wire, which can be critical in electrical applications, construction, and other uses where the wire's diameter directly affects its strength and conductivity.

For instance, gauge C typically denotes wire with a diameter that impacts its electrical resistance and current-carrying capability. Selecting the correct gauge is not just about function; it also ensures safety. If a wire is too thin for a particular application, it risks overheating, leading to potential fire hazards or equipment failure.

Gauge C in Sheet Metal

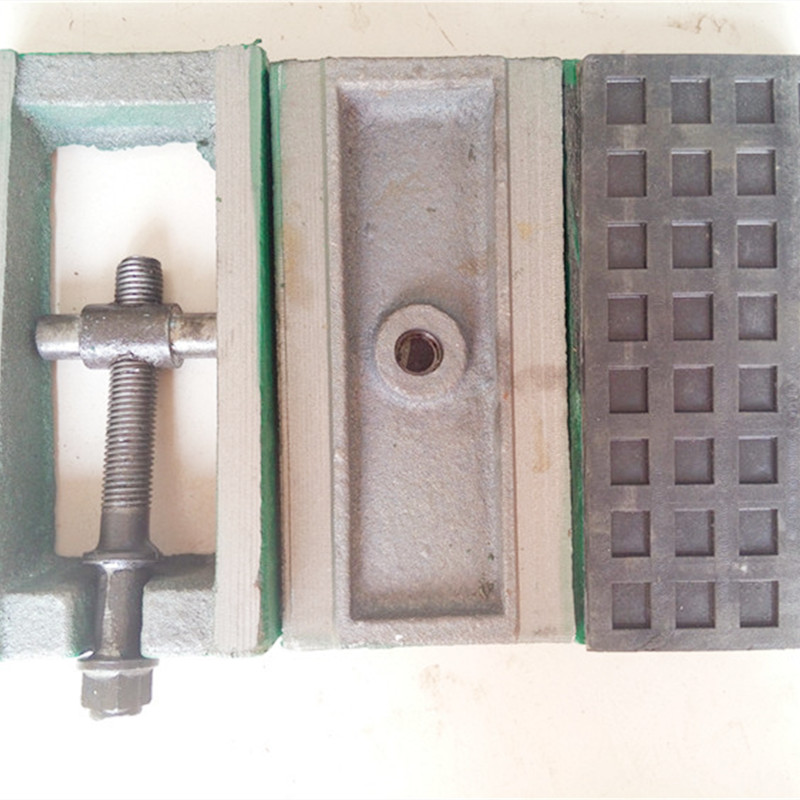

gauge c

In the realm of sheet metal, gauge C similarly finds relevance. The thickness of sheet metal is critical in determining its endurance to various forces. When choosing sheet metal, engineers often refer to gauge standards to ensure that the material will withstand the stresses of its intended application.

The gauge system for sheet metal operates on a similar principle a lower gauge number indicates a thicker material. For example, in the US standard system, 14-gauge sheet metal is thicker than 18-gauge sheet metal, which may be a determining factor in design and construction. The implications of using the wrong gauge can be significant, often resulting in structural failures or inadequacies that can be costly to rectify.

Importance of Compliance

Understanding gauge C is not merely an academic exercise; compliance with industrial standards is crucial. Many industries have strict guidelines regarding the materials that can be used for specific applications. For example, the automotive industry mandates particular gauges for electrical wiring and components to ensure vehicle safety and reliability. In construction, adhering to gauge specifications can be the difference between structural integrity and catastrophic failure.

Moreover, gauge standards are often aligned with regulatory requirements, meaning that failure to comply can lead to legal ramifications or product recalls. Thus, gauging the right type and size of materials, particularly in an age where quality control and regulatory compliance are essential, is critical for both safety and business success.

Conclusion

In summary, gauge C plays a significant role in the measurement of materials across various industries. Whether dealing with wire thickness or sheet metal, understanding the implications of different gauge standards is vital for manufacturing, safety, and compliance. As technology advances and the need for precision increases, the importance of properly gauging materials will continue to grow, supporting innovation and quality in engineering and manufacturing processes. As such, professionals in these fields must be well-versed in the nuances of gauge usage to ensure that they select the right materials for their specific needs and applications.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS