dec . 03, 2024 20:14 Back to list

Using Thread Ring Gauges for Accurate Measurement and Quality Control in Manufacturing Processes

The Importance of Thread Ring Gauges in Quality Assurance

In the world of manufacturing and engineering, precision is paramount. One of the critical aspects of ensuring that components fit together seamlessly is the accuracy of threaded connections. This is where thread ring gauges come into play. These specialized tools are vital for measuring and confirming the accuracy of external threaded parts, ensuring that they meet specified tolerances and standards.

What Is a Thread Ring Gauge?

A thread ring gauge is a cylindrical tool used to measure the external threads of a bolt or screw. Similar to how a wrench grips a nut, a thread ring gauge fits over the threaded portion of a part to assess its dimensions. The gauge contains precise internal threads that correspond to specific thread profiles and tolerances. By simply screwing the gauge onto the threaded part, operators can easily determine whether the component meets the required specifications.

Types of Thread Ring Gauges

Thread ring gauges come in several varieties, each designed for specific applications. The most common types include

1. Go and No-Go Gauges This set includes a 'Go' gauge, which should fit easily onto the thread being measured, and a 'No-Go' gauge, which should not fit. If the Go gauge cannot be threaded onto the part, or if the No-Go gauge can pass through, the part does not meet the required tolerance specifications.

2. Plug Gauges While not technically the same as thread ring gauges, plug gauges are often used in conjunction with them to provide a comprehensive assessment of threaded parts. Plug gauges measure the internal threads in nuts and other threaded holes.

3. Master Gauges These are high-precision gauges used to calibrate other gauges. They are crucial for maintaining the accuracy of the entire measuring system.

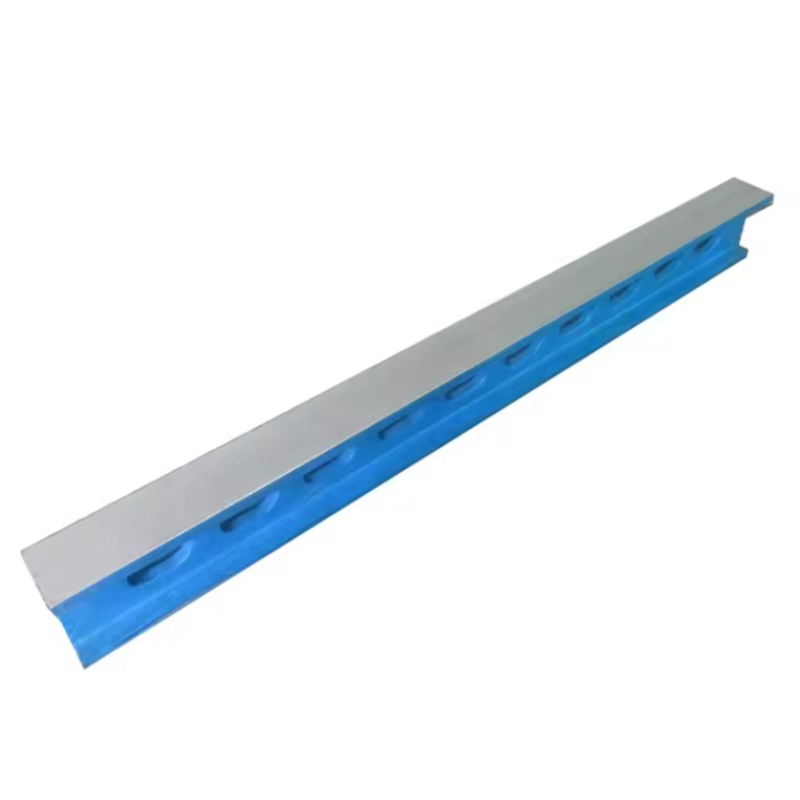

thread ring gauge is used for checking

Importance in Quality Control

The ramifications of poor thread quality can be substantial. Faulty threads can lead to component failures, safety hazards, and costly downtime in production. For instance, in industries such as aerospace and automotive, where reliable connections are crucial for safety, the importance of rigorous quality control cannot be overstated. Any failure in these sectors can have catastrophic consequences.

Using thread ring gauges in the quality assurance process helps manufacturers maintain high standards. By ensuring every threaded part meets the required specifications, companies can reduce the likelihood of defects, improve customer satisfaction, and lower costs associated with rework or product recalls.

The Testing Process

The process of using thread ring gauges is straightforward, yet it requires a particular skill set. Operators first clean the threaded part to remove any debris or oils that might affect measurements. They then select the appropriate thread gauge, either Go or No-Go, based on the specifications provided.

The operator screws the Go gauge onto the threaded part. If it fits smoothly and engages properly, the initial test is passed. Next, they check the No-Go gauge; if this gauge does not fit, the part is confirmed as being within specification. This simple, yet effective testing method ensures that even slight deviations in thread dimensions can be detected.

Conclusion

Thread ring gauges are indispensable tools in manufacturing and quality control processes. Their ability to provide quick, reliable measurements of thread profiles ensures that components fit together as intended, ultimately contributing to the safety and functionality of the final product. As manufacturers strive for greater quality and efficiency, the importance of precise measuring instruments like thread ring gauges will only continue to grow. By investing in these gauges and integrating them into regular quality assurance protocols, companies can safeguard their reputation and enhance customer trust in their products.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS