नोभ . 08, 2024 02:22 Back to list

Choosing the Right Size for Magnetic V Blocks in Precision Machining

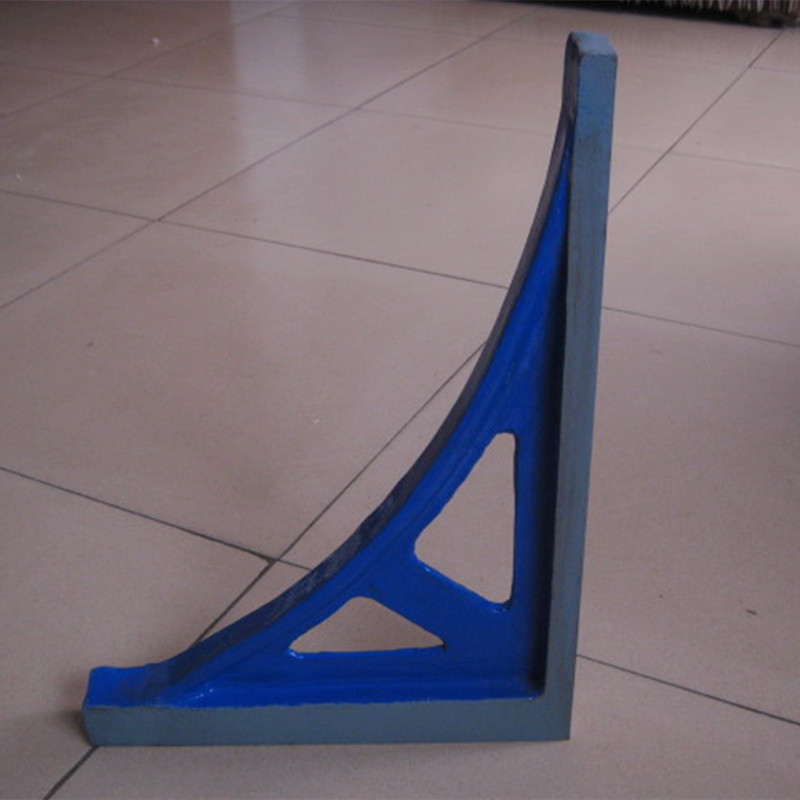

Understanding Magnetic V Block Sizes and Their Importance in Precision Machining

In the realm of precision machining and metalworking, the importance of having the right tools cannot be overstated. One such essential tool is the magnetic V block, a versatile fixture that plays a crucial role in holding workpieces securely in place during machining processes. Among the various specifications of these tools, the size of the magnetic V block is particularly significant, as it can greatly influence the efficiency and accuracy of machining operations.

What is a Magnetic V Block?

A magnetic V block is a precision tool designed to hold cylindrical or irregularly shaped workpieces securely, while allowing for easy access during machining operations. The V shape of the block provides a stable resting place for circular items, such as shafts or pipes, while the magnetic base ensures that the block remains firmly fixed to the work surface. This dual functionality makes it indispensable in workshops and manufacturing environments.

Why Size Matters

The size of the magnetic V block is a critical consideration for several reasons

1. Workpiece Compatibility Different machining tasks require different sizes of workpieces. Choosing a V block that matches the dimensions of the workpiece is essential for ensuring stability. An oversized block may be cumbersome and challenging to manipulate, while a block that is too small may not provide adequate support, leading to vibrations or movement during machining.

2. Versatility A larger magnetic V block can hold a variety of workpiece sizes and shapes, making it a more versatile tool for workshops that handle a diverse range of projects. Conversely, a smaller block might be better suited for precision tasks where fine tolerances are necessary, allowing for a tighter fit and improved machining accuracy.

3. Magnetic Strength The size of the magnetic V block often correlates with the strength of its magnetic hold. Larger blocks typically feature stronger magnets capable of securing heavier workpieces. This aspect is particularly crucial when working with larger, heavier components that demand greater stability to mitigate the risk of accidents or inaccuracies during machining.

magnetic v block size

4. Ease of Use Larger blocks can be more challenging to manipulate, particularly in tight workspaces. Conversely, smaller blocks are easier to position but may lack the stability required for certain tasks. Finding a balance in size is vital for ensuring ease of use without compromising on functionality.

How to Choose the Right Size

When selecting a magnetic V block, consider the following factors

- Workpiece Dimensions Measure the size and shape of the workpieces you will be machining. This assessment will guide you in choosing a V block that offers adequate support.

- Magnetic Strength Look for specifications that indicate the holding power of the magnetic base. Ensure that it can securely hold the workpiece throughout the machining process.

- Operational Environment Take into account the workspace where the block will be used. A smaller shop may necessitate more compact tools, whereas a larger shop can accommodate larger fixtures.

- Material The material of the V block itself also plays a role in its effectiveness. Blocks made from high-quality steel tend to provide better durability and performance over time.

Conclusion

In summary, the size of a magnetic V block is a fundamental aspect that impacts its effectiveness in precision machining. By understanding the importance of size in relation to workpiece compatibility, versatility, magnetic strength, and usability, machinists can make informed decisions when selecting tools for their operations. Ultimately, investing in the right magnetic V block not only enhances machining accuracy but also improves overall workflow efficiency. Therefore, whether you are setting up a new workshop or upgrading existing tools, do not overlook the significance of magnetic V block size in your machining projects.

-

Right Angle Ruler Innovations in Measuring ToolsNewsJul.18,2025

-

Parallel Ruler Maintenance for Long-Term AccuracyNewsJul.18,2025

-

Magnetic V Block 4 Inch Cost Effectiveness AnalysisNewsJul.18,2025

-

Internal Thread Gauge Innovations for Faster InspectionNewsJul.18,2025

-

Ground Anchor Applications in Construction and LandscapingNewsJul.18,2025

-

Butterfly Valve Types StandardsNewsJul.18,2025

Related PRODUCTS