फेब . 13, 2025 02:21 Back to list

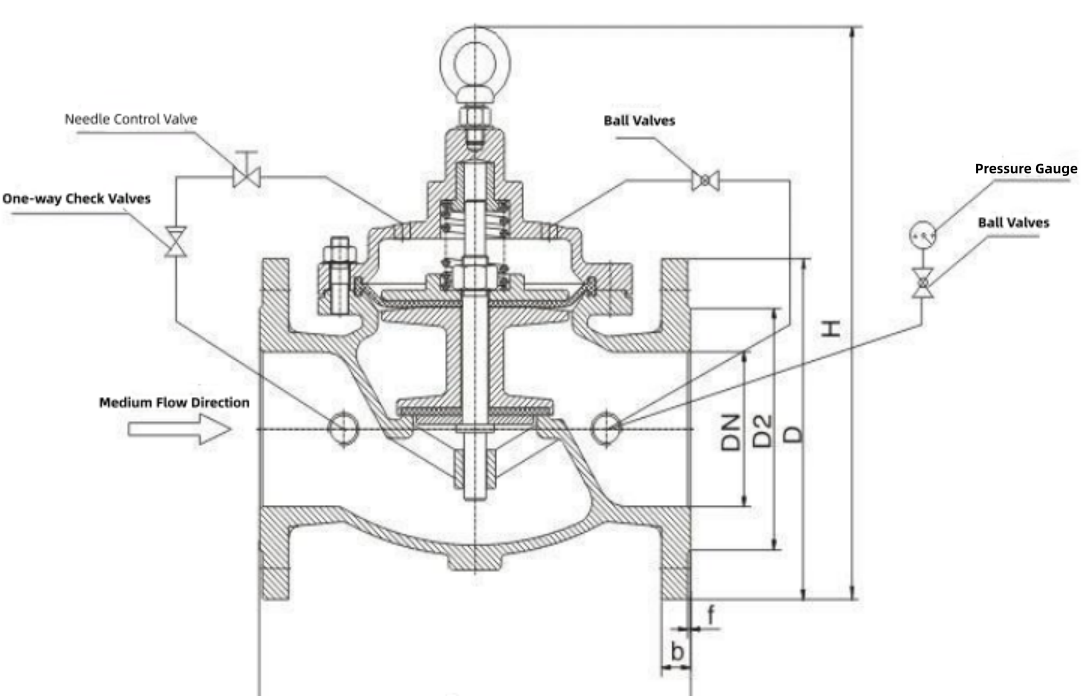

check valve assy

The 4 check valve made of cast iron is an indispensable element in a wide array of industrial applications. Its robust design and durable material make it a preferred choice for industries ranging from water treatment to petrochemicals. To understand why this particular valve is held in high regard, let us explore its make, utility, and the inherent advantages it brings to complex fluid handling systems.

Selection of a 4 check valve in cast iron should be guided by specific operational requirements. Pressure ratings, temperature tolerance, and the chemical composition of the fluid being handled are critical factors to consider. The valve should be equipped to withstand the most challenging conditions it might encounter within the system. Furthermore, consulting with valve specialists or manufacturers ensures that the chosen valve meets the unique demands of your application, bolstering system integrity and performance. Trustworthiness in the components we choose for industrial systems cannot be overstated. Opting for a valve from a reputable manufacturer guarantees adherence to international quality standards and regulatory requirements. It is imperative to choose suppliers who offer comprehensive warranty and support services. This assurance is vital in today's fast-paced industrial landscape, where equipment reliability directly translates to operational efficiency and business continuity. In conclusion, the 4 check valve cast iron is a pivotal component in ensuring the longevity and efficiency of industrial fluid systems. Its design, construction, and functionality combine to offer unparalleled performance in demanding environments. By choosing the right valve and maintaining regular oversight, industries can protect their investments, optimize system performance, and enhance safety. In this era where every component plays a critical role in the broader operational framework, understanding the significance of such valves is key to achieving sustained industrial success.

Selection of a 4 check valve in cast iron should be guided by specific operational requirements. Pressure ratings, temperature tolerance, and the chemical composition of the fluid being handled are critical factors to consider. The valve should be equipped to withstand the most challenging conditions it might encounter within the system. Furthermore, consulting with valve specialists or manufacturers ensures that the chosen valve meets the unique demands of your application, bolstering system integrity and performance. Trustworthiness in the components we choose for industrial systems cannot be overstated. Opting for a valve from a reputable manufacturer guarantees adherence to international quality standards and regulatory requirements. It is imperative to choose suppliers who offer comprehensive warranty and support services. This assurance is vital in today's fast-paced industrial landscape, where equipment reliability directly translates to operational efficiency and business continuity. In conclusion, the 4 check valve cast iron is a pivotal component in ensuring the longevity and efficiency of industrial fluid systems. Its design, construction, and functionality combine to offer unparalleled performance in demanding environments. By choosing the right valve and maintaining regular oversight, industries can protect their investments, optimize system performance, and enhance safety. In this era where every component plays a critical role in the broader operational framework, understanding the significance of such valves is key to achieving sustained industrial success.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS