Oct . 21, 2024 23:31 Back to list

hydraulic check valve

Understanding Hydraulic Check Valves

Hydraulic check valves are essential components in fluid control systems, playing a crucial role in maintaining the desired flow of liquids in hydraulic circuits. These valves are designed to allow flow in one direction while preventing reverse flow, thereby ensuring the efficiency and safety of various hydraulic applications.

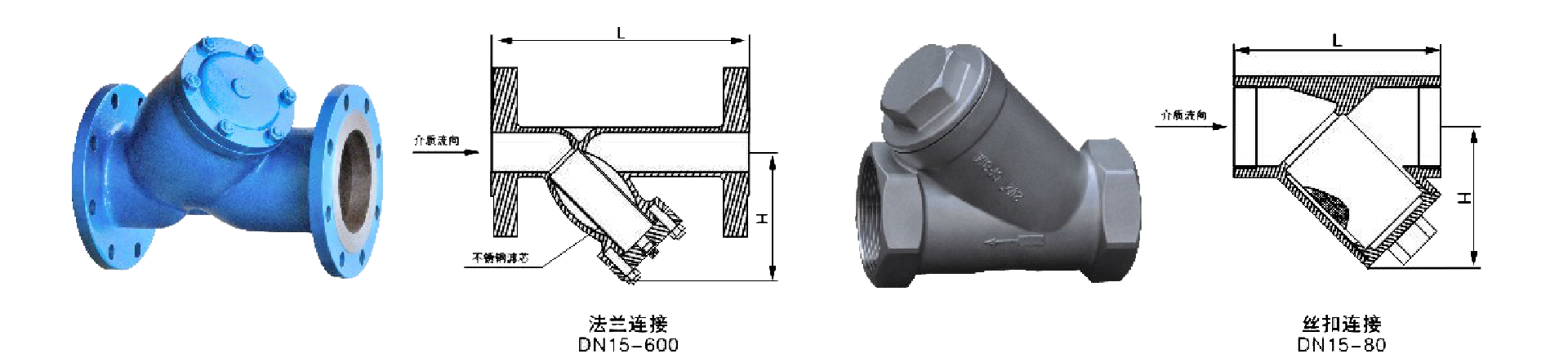

The basic mechanism of a hydraulic check valve consists of a body, a sealing element, and an inlet and outlet port. The sealing element, often a disc or ball, is pushed away from the seat when fluid flows in the intended direction. However, if there is a reversal of flow, the sealing element returns to its seat, effectively blocking the fluid and preventing backflow. This mechanism is critical in applications such as hydraulic machinery, pumps, and pipelines, where backflow can lead to equipment damage, contamination, and operational inefficiencies.

There are several types of hydraulic check valves, each suited for different applications. For instance, ball check valves utilize a spherical ball that seats against an opening to prevent reverse flow. Similarly, swing check valves feature a pivoting disc that swings open and closed based on flow direction. In contrast, lift check valves employ a movable disc that lifts off the seat under the influence of flow pressure. The choice of the valve type often depends on factors such as the required flow rate, pressure levels, and specific application needs.

hydraulic check valve

One of the vital advantages of using hydraulic check valves is that they enhance system reliability. By preventing backflow, these valves protect pumps and other components from potential damage caused by fluid surges or pressure fluctuations. Additionally, hydraulic check valves contribute to energy efficiency by ensuring that the system maintains optimal flow, reducing the workload on pumps and motors.

Regular maintenance and monitoring of hydraulic check valves are essential to ensure their proper functionality. Over time, sediment or debris can accumulate, causing the valve to malfunction. Routine inspections can help identify issues early, allowing for timely repairs or replacements, thereby extending the lifespan of the hydraulic system as a whole.

In summary, hydraulic check valves are vital for ensuring the proper operation of hydraulic systems. By preventing backflow and maintaining efficient fluid flow, these valves play a significant role in various industrial and commercial applications, ensuring reliability and enhancing overall system performance. Proper selection, installation, and maintenance of these components are essential for optimal hydraulic functionality.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS