Jul . 15, 2025 10:20 စာရင်းသို့ ပြန်သွားရန်

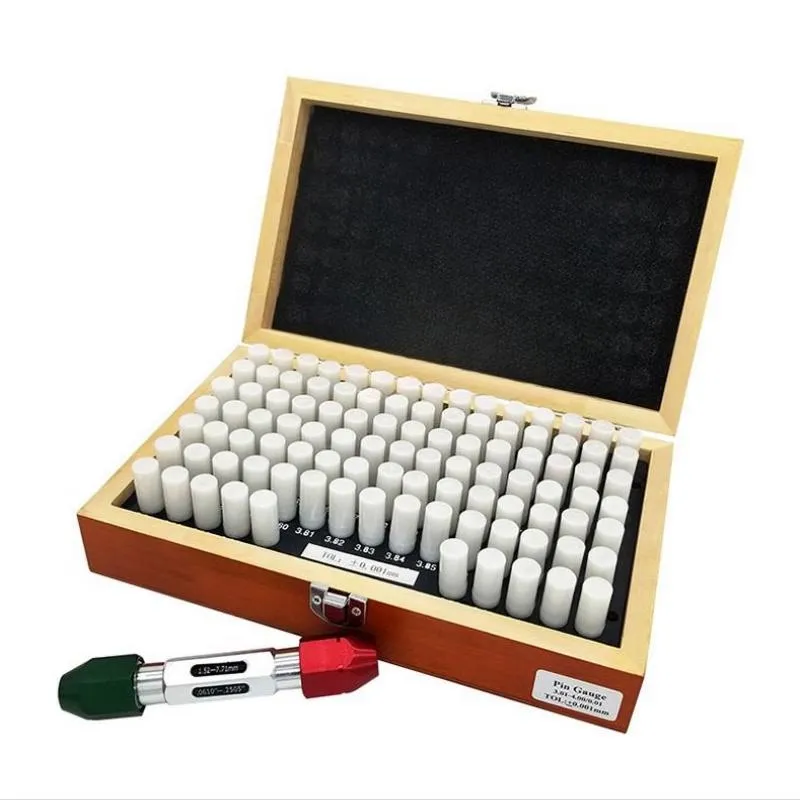

Hardened Pin Gauge Resists Wear from Frequent Use

In the precision-driven landscape of manufacturing and quality control, the durability of measurement tools is as critical as their accuracy. Storaen (Cangzhou) International Trading Co. presents pin gauge solutions engineered with hardened materials to withstand the rigors of frequent use. Our machinist gauge pins products combine robust construction with precise design, ensuring reliable performance even in high-volume production environments. By prioritizing wear resistance and longevity, we empower industries to maintain strict quality standards without compromising on tool durability.

Storaen (Cangzhou) International Trading Co.’s Expertise in Hardened Pin Gauge Production

Storaen (Cangzhou) International Trading Co., based in Botou, China, has established itself as a trusted provider of industrial measurement tools. Specializing in pin gauge manufacturing, our team leverages advanced heat-treatment processes and premium materials to create tools that excel in wear resistance. We understand that frequent use in machining and inspection can degrade standard gauges, which is why our thread pin gauge models undergo rigorous hardening to maintain precision over time. With a commitment to ISO-compliant quality control, we ensure each gauge meets the highest standards for durability and accuracy.

The Engineering Behind Wear-Resistant Pin Gauge Materials

Our pin gauge products are crafted from GCr15 bearing steel, a material renowned for its exceptional hardness and wear resistance. Through a meticulous heat-treatment process, the steel is hardened to withstand repeated insertion and extraction from holes, a common cause of wear in measurement tools. This hardening not only extends the gauge’s lifespan but also preserves its dimensional stability, ensuring consistent accuracy even after prolonged use. The surface finish of our machinist gauge pins is precision-ground to minimize friction during measurements, further reducing wear and tear while maintaining a smooth operation.

Thread Pin Gauge: Specialized Design for Thread Inspections

- Storaen’s thread pin gaugeis specially engineered for inspecting internal threads in components like nuts, sockets, and threaded holes.

- These gauges feature a threaded design that matches the pitch and profile of the threads being measured, enabling precise "go/no-go" assessments.

- Similar to our standard pin gaugemodels, thread pin gauge products are hardened to resist wear from repetitive threading during inspections.

- This specialized design ensures that even in high-volume production lines, the gauges maintain thread accuracy, preventing false passes and ensuring component compatibility.

Pin Gauge FAQS

How does hardening improve the pin gauge’s durability?

Hardening the pin gauge through heat treatment increases the steel’s hardness, making it more resistant to abrasion and deformation from frequent use. This process transforms the steel’s microstructure, creating a surface that can withstand the friction and pressure of repeated measurements without wearing down. The result is a gauge that maintains its dimensional accuracy over an extended lifespan, even in high-use environments.

Can thread pin gauge be used for different thread types?

Yes, Storaen’s thread pin gauge is available in various thread types and sizes to accommodate different applications. Whether inspecting metric, imperial, or specialized threads, our gauges are designed to match the specific pitch and profile requirements. This versatility allows manufacturers to use our thread pin gauge across different product lines, ensuring consistent quality control for various threaded components.

What maintenance is required for machinist gauge pins?

Maintenance for machinist gauge pins is minimal due to their hardened construction. Regular cleaning with a soft cloth to remove debris and light lubrication of the surface can help prevent corrosion and maintain smooth operation. Storing gauges in a protective case when not in use also safeguards them from accidental damage. Periodic calibration against a master standard is recommended to ensure ongoing accuracy, but the hardened material reduces the frequency of such calibrations.

Are hardened pin gauges suitable for high-temperature environments?

While our pin gauge products are hardened to resist wear, they are best suited for standard industrial temperatures. Prolonged exposure to high temperatures can affect the steel’s hardness and dimensional stability. For applications involving extreme heat, we recommend consulting our team for specialized gauge solutions that can withstand elevated temperatures while maintaining accuracy.

How do I select the correct pin gauge size for my application?

Selecting the right pin gauge size involves matching the gauge diameter to the hole or thread being measured. Storaen offers gauges in a range of standard sizes, and our team can assist with custom specifications if needed. For thread inspections, the thread pin gauge should match the thread’s nominal diameter and pitch. Our product documentation provides clear size charts and tolerance information to guide accurate selection for any application.

Welcome to www.strmachinery.com ! Discover our premium industrial equipment, specializing in heavy-duty machinery, precision tools, and manufacturing solutions for construction, agriculture, and industrial sectors. Engineered for durability and efficiency, our products meet global standards, ensuring reliable performance in demanding environments. From innovative machinery designs to customizable components, we offer tailored solutions to fit your project needs. Explore our range of robust, high-performance equipment today. Shop now and experience our commitment to excellence—where every machine is crafted to drive productivity and withstand the toughest industrial challenges!

-

Thread Plug Gauge Our Promise of Measurement Excellenceသတင်းAug.22,2025

-

Gauge Pin Class Reflecting Quality Legacyသတင်းAug.22,2025

-

Check Valve Types for High Rise Buildingsသတင်းAug.22,2025

-

Water Control Valve for Irrigation Systemsသတင်းAug.22,2025

-

Gate Valve with Soft Seal Technologyသတင်းAug.22,2025

-

Y Type Strainer for Oil and Gas Applicationsသတင်းAug.22,2025

ဆက်စပ်ထုတ်ကုန်များ