Sep . 28, 2024 09:57 Back to list

Equilibrium Globe Valve for Precision Control in Fluid Systems

Understanding Balanced Globe Valves Functionality, Benefits, and Applications

In the realm of fluid control systems, few components play as crucial a role as valves. Among the many types of valves used across various industries, balanced globe valves stand out for their unique design and functionality. This article will delve into the intricacies of balanced globe valves, exploring their structure, advantages, and common applications.

What is a Balanced Globe Valve?

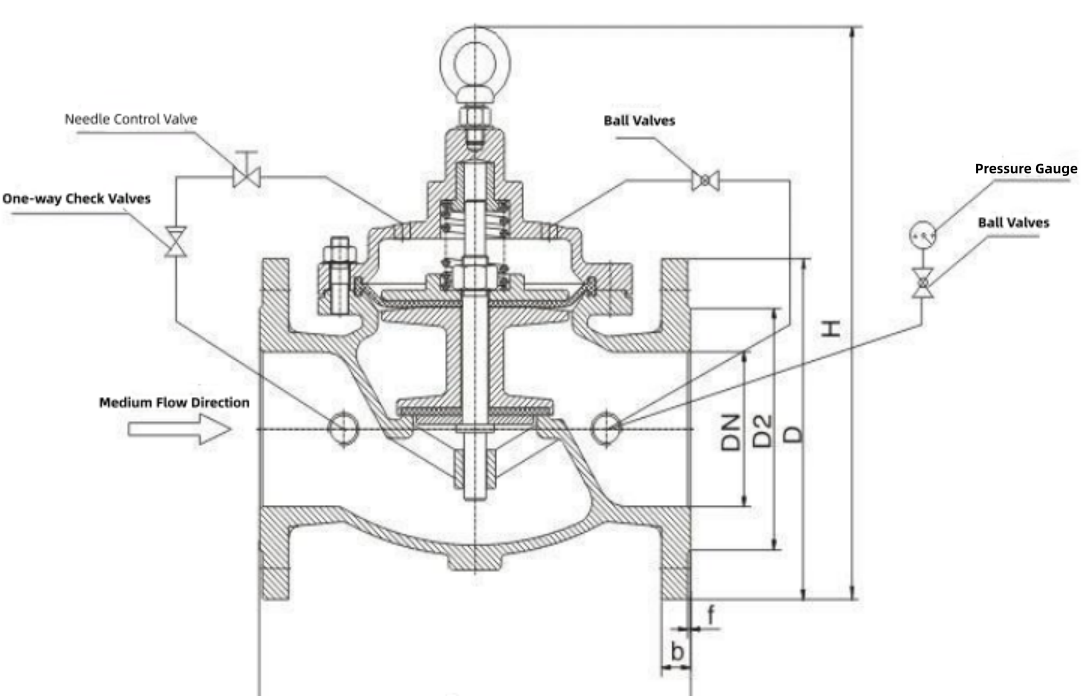

A balanced globe valve is a type of valve that is designed to regulate fluid flow with minimal pressure drop and reduced friction losses. Unlike standard globe valves, which can generate significant resistance due to their internal configuration, balanced globe valves feature a unique design that allows them to maintain uniform pressure on both sides of the disc or plug. This balance is achieved through the use of an internal balancing mechanism, which can be a secondary port that allows fluid to flow around the disc, equalizing the pressure loads during operation.

Structure and Components

A balanced globe valve consists of several key components

1. Body The main structure of the valve that houses the internal components. It is typically made from materials like cast iron, stainless steel, or brass, depending on the application.

2. Disc/Plug This is the movable part that opens and closes to control the flow of fluid. In balanced globe valves, the disc design is crafted to minimize turbulence and pressure losses.

3. Stem Connected to the disc, the stem allows for the manual or automated operation of the valve. It can be turned using a handwheel or through an actuator.

4. Seat The surface against which the disc closes to create a seal, preventing any leakage when the valve is in the closed position.

5. Balancing Mechanism This feature distinguishes balanced globe valves from standard types, helping to alleviate pressure differentials on the disc.

Advantages of Balanced Globe Valves

Balanced globe valves offer numerous benefits, making them a preferred choice in many applications

balanced globe valve

1. Reduced Pressure Drop By equalizing the pressure around the disc, balanced globe valves experience less resistance, leading to lower energy consumption in pumping systems.

2. Improved Flow Control The design allows for precise control of flow rates, enabling efficient management of fluid processes.

3. Lower Noise Levels The reduced turbulence associated with balanced globe valves often translates to quieter operation, which is a significant factor in noise-sensitive environments.

4. Extended Service Life The balanced design reduces wear on the internal components, contributing to a longer service life and reduced maintenance costs.

5. Versatility Balanced globe valves can be used in a wide range of industries, including water treatment, chemical processing, HVAC systems, and oil and gas, making them versatile solution providers.

Common Applications

Balanced globe valves are utilized in various applications due to their reliability and efficiency. Some common industries and scenarios where balanced globe valves are employed include

- Water Distribution They help in the precise management of water flow within municipal supply systems and treatment plants.

- Chemical Processing In chemical plants, these valves ensure the accurate flow of corrosive and hazardous materials while minimizing the risk of leaks.

- Power Generation Balanced globe valves control the steam and water flows in power plants, contributing to the efficiency of energy production.

- HVAC Systems They regulate the distribution of heating and cooling fluids, ensuring comfortable indoor environments.

Conclusion

Balanced globe valves represent a significant advancement in valve technology, offering numerous benefits over traditional valve types. Their unique design enables efficient flow control with reduced pressure losses, making them suitable for a vast array of applications. As industries continue to seek solutions that enhance operational efficiency while minimizing energy consumption, balanced globe valves will undoubtedly remain a vital component in the fluid control landscape. Understanding their functionality and advantages is essential for engineers and decision-makers in optimizing system performance and reliability.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS