Oct . 14, 2024 07:17 Back to list

Understanding Y Strainer and Its Role in Steam Trap Systems for Efficient Operations

Understanding Y-Strainer and Steam Trap Key Components in Fluid Management

In industrial applications, efficient fluid management is crucial for maintaining operational integrity. Among the myriad of devices used in these systems, the Y-strainer and steam trap play pivotal roles in ensuring that processes run smoothly. Each component serves a specific function that contributes to the overall performance and reliability of steam systems and liquid handling.

What is a Y-Strainer?

A Y-strainer is a mechanical filter used to capture impurities from liquids and gases in a pipeline. As the name suggests, its shape resembles the letter Y, consisting of a body with an inlet and outlet and a straining element. The straining element, often made of perforated metal or mesh, traps unwanted particles, preventing them from entering downstream equipment.

The installation of a Y-strainer is essential in various applications, including water treatment, chemical processing, and steam systems. By effectively filtering out debris, sediment, and other contaminants, Y-strainers help prevent equipment damage, maintain flow rates, and enhance system efficiency. Regular maintenance is key, as the strainer should be cleaned or replaced as needed to ensure optimal performance.

The Role of Steam Traps

A steam trap is a mechanical device designed to discharge condensate and non-condensable gases while trapping steam in the system. In steam applications, steam traps are critical elements that ensure energy efficiency and proper operation. If condensate is not removed promptly, it can lead to water hammer, reduced efficiency, and potential damage to equipment.

There are various types of steam traps, including thermostatic, mechanical, and thermodynamic traps, each designed to handle specific applications and conditions. The choice of steam trap depends on factors such as pressure, temperature, and the specific needs of the steam system. Effective steam trap operation enhances energy conservation and reduces operational costs.

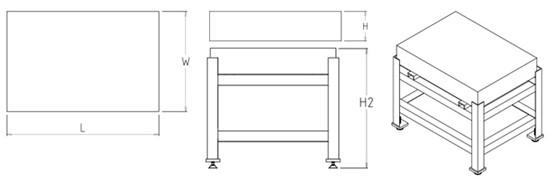

y strainer steam trap

The Synergy Between Y-Strainers and Steam Traps

In steam systems, Y-strainers and steam traps work in tandem to ensure optimal performance. The Y-strainer prevents contaminants from damaging steam traps by filtering incoming steam and associated condensate. Without a Y-strainer, foreign particles could block or damage the trap, potentially leading to malfunctions or failures in the system.

Additionally, implementing a Y-strainer upstream of a steam trap reduces maintenance frequency and extends the lifespan of the trap. By preventing dirt and debris from entering the steam trap, operators can minimize downtime and enhance overall system reliability.

Conclusion

When it comes to fluid management in industrial applications, the combination of Y-strainers and steam traps is essential. Y-strainers provide critical filtration to protect downstream equipment, while steam traps ensure the efficient removal of condensate and non-condensable gases in steam systems. Together, they contribute to enhanced performance, energy efficiency, and longevity of plant operations.

In order to maximize the benefits of these components, regular inspection and maintenance are necessary. Operators should develop a routine maintenance schedule to monitor the condition of both Y-strainers and steam traps. This proactive approach not only prevents potential problems but also optimizes the overall effectiveness of the system.

In summary, understanding the functions and interrelationship of Y-strainers and steam traps is vital for anyone involved in fluid management. These components are more than just accessories; they are integral to achieving operational excellence within a range of industries. Investing in quality Y-strainers and steam traps, alongside sound maintenance practices, paves the way for improved efficiency and reduced costs in fluid handling processes.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS