Nov . 09, 2024 06:32 Back to list

Granite Surface Plate with Support Stand for Precision Measurement and Inspection

The Importance of Granite Surface Plates with Stands in Precision Measurement

In the world of precision engineering and manufacturing, accuracy is paramount. Whether in machine shops, laboratories, or quality control environments, the ability to measure and inspect parts accurately can mean the difference between a well-functioning product and costly errors. One essential tool that plays a crucial role in achieving precision is the granite surface plate, especially when paired with a sturdy stand.

Understanding Granite Surface Plates

Granite surface plates are flat, level surfaces made from natural granite stone. They are prized for their stability, durability, and inherent resistance to temperature changes, making them ideal for precision measurement tasks. The hardness of granite allows it to withstand wear and tear from tools and equipment, and its non-porous nature means it won't absorb liquids, which can lead to degradation or contamination.

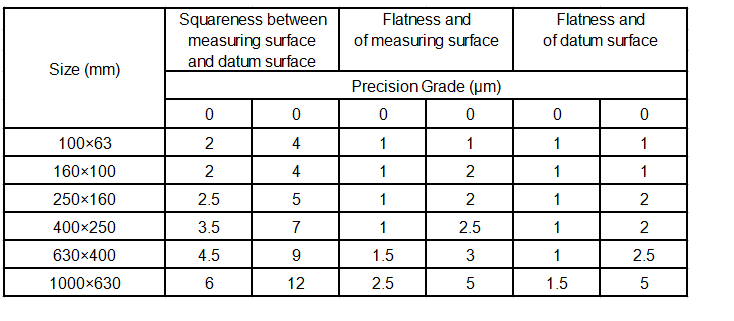

The primary function of a granite surface plate is to provide a reliable and flat reference point against which measurements can be taken. This can include checking the flatness of a part, aligning components, or serving as a base for precision instruments such as dial indicators and height gauges. The accuracy of these measurements is critical for quality control in manufacturing processes.

The Advantages of Using a Stand

While granite surface plates can be used on any stable, flat surface, incorporating a stand offers several advantages that enhance their usability and effectiveness. A dedicated stand ensures that the granite plate is positioned at a comfortable working height, which reduces strain on operators and enhances ergonomics. This is especially important in environments where measurements are taken repeatedly, as it allows for a more efficient workflow and minimizes fatigue.

Additionally, a stand elevates the surface plate, allowing for better accessibility and visibility. This can be particularly beneficial when working with larger components or complex assemblies. A raised surface not only improves the line of sight for the operator but also reduces the risk of contamination or damage from other work surfaces or equipment.

granite surface plate with stand

Stability and Vibration Damping

One of the critical features of a granite surface plate is its ability to remain stable during measurement tasks. However, stability can be compromised if the plate is placed on an uneven or unstable surface. A dedicated stand designed for granite surface plates typically comes with adjustable feet, allowing for fine adjustments that ensure the plate is perfectly level. This is vital for achieving accurate measurements.

Furthermore, many stands incorporate features that dampen vibrations. In a busy workshop or laboratory, vibrations from machinery or foot traffic can transfer to the surface plate, leading to erroneous readings. A quality stand can help absorb these vibrations, maintaining the integrity of measurements taken on the granite surface plate.

Maintenance and Care

Granite surface plates require regular maintenance to ensure their continued accuracy and longevity. When combined with a stand, it becomes easier to keep the surface plate clean and in good condition. The elevated design helps prevent accidental damage during cleaning and reduces the risk of scratches or other wear.

Routine inspections for chips, cracks, or other imperfections are also simplified when the surface plate is securely mounted on a stand. Regular calibration against known standards will help uphold the precision needed for critical measurements.

Conclusion

Granite surface plates are indispensable tools for achieving high levels of precision in various industries. Pairing them with a sturdy, adjustable stand enhances their functionality, making them more user-friendly and effective. By improving ergonomics, stability, and ease of maintenance, a granite surface plate with a stand is a wise investment for any facility focused on quality and precision. As industries continue to seek higher standards of accuracy, such tools will remain vital in the pursuit of excellence in manufacturing and engineering.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS