Dis . 05, 2024 15:35 Back to list

Exploring the Importance of Surface Plates in Precision Engineering Applications

The Essential Role of Surface Plates in Precision Metrology

In the realm of precision engineering and quality control, surface plates are invaluable tools that serve as the foundation for accurate measurement and alignment tasks. Understanding the importance, types, and applications of surface plates can greatly enhance the efficiency and effectiveness of various manufacturing and inspection processes.

What is a Surface Plate?

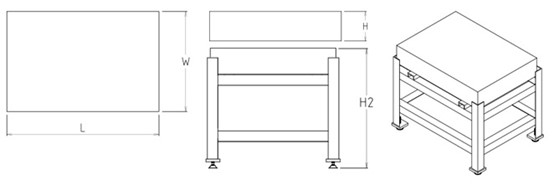

A surface plate is a flat, solid platform made from durable materials like granite, cast iron, or aluminum. These plates are designed to provide a reliable reference plane for measuring the dimensions of manufactured components. Their primary function is to support workpieces during inspection and machining while ensuring a high level of accuracy.

Surface plates come in various sizes and thicknesses, catering to different requirements. Granite surface plates, for instance, are favored in many industries due to their natural resistance to wear, thermal stability, and non-magnetic properties, which prevent any disturbance during measurements. Cast iron surface plates, on the other hand, are renowned for their robustness and strength, making them suitable for heavy-duty applications.

Importance of Surface Plates in Metrology

Metrology, the science of measurement, relies heavily on the accuracy of instruments and measurement systems. Surface plates play a crucial role in this domain by providing a stable and flat reference across which accurate measurements can be made. The precise flatness and stability of a surface plate are essential for ensuring that measurements taken are valid and repeatable.

In contexts where even minor discrepancies can lead to significant errors, such as aerospace, automotive, and precision manufacturing industries, the importance of surface plates cannot be overstated

. For instance, when using calipers, micrometers, or coordinate measuring machines (CMMs), a surface plate serves as the base reference point that enhances the reliability of these measurements.Applications of Surface Plates

The applications of surface plates are vast and varied

1. Inspection and Quality Control Surface plates are extensively used in inspection rooms where parts are evaluated for conformity to specifications. They provide a reference plane for checking dimensions, ensuring that manufactured components meet strict tolerances and standards.

surface plate

2. Machining and Assembly Work During machining processes, surface plates help in aligning components accurately before they are machined or assembled. This ensures that the finished product is fabricated according to its design specifications.

3. Setup for Coordinate Measuring Machines (CMM) CMMs are sophisticated devices used for measuring the physical geometrical characteristics of an object. Surface plates provide the necessary flat, stable reference surface for these machines, enabling them to perform precise 3D measurements.

4. Tool Calibration Surface plates are essential for calibrating various precision tools and instruments. By providing a flat measuring surface, they help technicians ensure that equipment is functioning correctly and providing accurate readings.

Maintenance and Care of Surface Plates

To retain their accuracy, surface plates require regular maintenance and care. Here are some best practices

- Regular Cleaning Surface plates should be kept free of debris and contaminants. A soft cloth and gentle cleaning agents are recommended to avoid scratching the surface.

- Proper Leveling Ensuring that the plate is correctly leveled is essential for accurate measurements. Leveling can be accomplished using shims or adjustable leveling feet.

- Avoiding Heavy Impacts While surface plates are durable, it is crucial to avoid heavy impacts that could cause chips or dents, compromising their flatness.

Conclusion

Surface plates are fundamental to the practice of precision measurement and quality control in numerous industries. Their ability to provide a stable, flat reference surface enables manufacturers and engineers to maintain accuracy and consistency across their work processes. Investing in a quality surface plate and adhering to maintenance protocols can significantly enhance the overall quality and reliability of manufactured products, ultimately contributing to a company’s success in today’s competitive market.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS