Okt . 31, 2024 14:32 Kembali kepada senarai

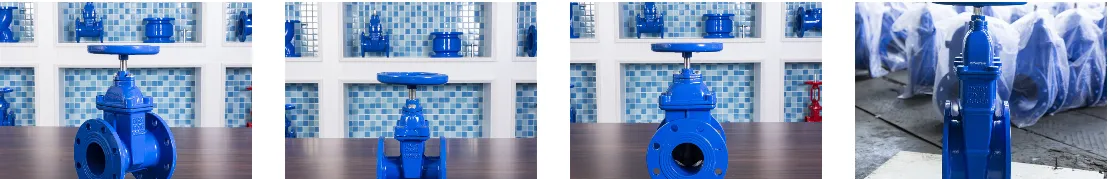

Gate Valve and Globe Valve

In the realm of fluid control, gate valves, and globe valves serve crucial roles, yet they cater to different operational needs. Both are essential components in piping systems, but their design and function distinguish them significantly. In this post, we will delve into the unique characteristics of gate valves and globe valves, ultimately guiding industry professionals to select the most appropriate option for their specific applications.

What is a Gate Valve?

Gate valves are designed to provide a straightforward, on/off flow control with minimal pressure drop. They consist of a wedge-shaped disk that moves up and down, which either allows or blocks fluid passage. One of the primary advantages of a gate valve is its ability to function effectively in fully open or closed positions, making it an excellent choice for systems where fluid flow is not frequently altered.

Key Features of Gate Valves:

- Minimal Flow Resistance: When fully open, the gate valve offers little resistance to fluid flow, resulting in lower energy consumption.

- Durability: Made from robust materials, gate valves are built to withstand high-pressure environments.

- Applications: They are well-suited for applications such as water supply, sewage treatment, and oil and gas services, where isolation of flow is crucial.

What is a Globe Valve?

In contrast, globe valves are designed for throttling and regulating flow rather than merely shutting it on or off. The internal structure of a globe valve features a spherical body with an internal baffle that creates a tortuous path for fluid. This design gives globe valves their unique ability to regulate flow efficiently, making them ideal for applications where precise control is required.

Key Features of Globe Valves:

- Flow Regulation: Globe valves provide excellent control over fluid flow, making them indispensable for systems requiring precise adjustments.

- Higher Pressure Drop: Unlike gate valves, globe valves experience a higher pressure drop due to their flow path design.

- Applications: Commonly used in heating systems, cooling systems, and industrial processes, globe valves are valuable for applications where constant adjustments of flow are critical.

Choosing the Right Valve

When deciding between gate valves and globe valves, it is essential to consider the specific needs of your system. If your priority is to lower energy loss and simply isolate fluid flow, then gate valves are the recommended choice. Conversely, if you require the capability to finely tune the flow rate, globe valves are the superior option.

Both gate valves and globe valves have distinct advantages and applications in various industries. Understanding the differences between gate valves and globe valves allows professionals to make informed decisions tailored to their operational requirements. Whether your application demands the robust isolation capability of a gate valve or the precise control of a globe valve, each plays a vital role in ensuring the efficient management of fluid systems.

For best results, consider consulting with valve suppliers to help you identify the most effective solution for your unique needs.

-

Thread Plug Gauge Requires Careful HandlingBeritaJul.29,2025

-

Surface plate calibrationBeritaJul.29,2025

-

Ring Gauge Ensures Machining AccuracyBeritaJul.29,2025

-

Pad Iron Reinforces Anchor PointsBeritaJul.29,2025

-

Ground anchor stabilizes embankmentsBeritaJul.29,2025

-

Granite Box Maintains Precision FlatnessBeritaJul.29,2025

Produk Berkaitan