जुलै . 09, 2025 12:03 सूचीकडे परत

Measuring Tool Basics for Engineers

When working with measuring tools, engineers need to understand the various different measuring tools available and their specific applications. High-quality engineering measuring tools are essential for precision work across multiple industries. This guide explores the fundamental types and uses of these critical instruments.

Essential Measuring Tools for Precision Work

- Calipers - Versatile measuring tools that can take internal, external, and depth measurements with high accuracy

• Micrometers - Precision engineering measuring tools capable of measuring to 0.001mm or better

• Dial indicators - Critical for measuring small linear distances and checking alignment

• Height gauges - Essential different measuring tools for vertical measurement and marking

• Surface plates - Provide the reference plane for all precision measurements

Specialized Engineering Measuring Tools

- Optical comparators - Project magnified silhouettes of parts for precise measurement and inspection

• Coordinate measuring machines (CMMs) - Advanced engineering measuring toolsfor 3D measurement of complex parts

• Bore gauges - Specialized different measuring toolsfor measuring internal diameters

• Thread gauges - Essential for verifying thread pitch and profile accuracy

• Surface roughness testers - Measure microscopic surface texture variations

Choosing the Right Measuring Tools

- Consider measurement range - Select measuring toolsappropriate for your expected size ranges

• Evaluate accuracy requirements - Different applications demand different levels of precision from engineering measuring tools

• Material compatibility - Ensure different measuring toolsare made from materials suitable for your work environment

• Frequency of use - Heavy-duty applications require more durable instruments

• Calibration needs - Factor in maintenance requirements for ongoing accuracy

Proper Use and Maintenance of Measuring Tools

- Always handle precision measuring toolswith care to maintain accuracy

• Store engineering measuring toolsin protective cases when not in use

• Clean different measuring tools properly after each use to prevent buildup

• Follow manufacturer guidelines for lubrication and adjustment

• Establish regular calibration schedules to ensure continued precision

Engineering Measuring Tools FAQS

Q: How do engineering measuring tools differ from general measuring tool types in industrial applications?

A: Engineering measuring tools are designed for precision tasks like structural analysis or component fabrication, featuring higher accuracy standards (e.g., laser distance meters with ±1mm error) compared to general measuring tools like tape measures. They often include specialized functions such as 3D scanning or thermal imaging, critical for complex engineering projects.

Q: What are the most essential different measuring tools used by engineers in fieldwork?

A: Engineers rely on tools like digital calipers for precise dimensions, total stations for surveying, and torque wrenches for mechanical installations. These different measuring tools cater to specific needs—for example, moisture meters for construction or oscilloscopes for electrical engineering—ensuring accuracy in diverse environments.

Q: How does calibration impact the performance of engineering measuring tools versus standard measuring tools?

A: Engineering measuring tools require frequent calibration (e.g., every 6–12 months) to maintain compliance with ISO standards, unlike basic measuring tools. Neglecting calibration can lead to errors in projects like bridge construction, where even minor miscalculations pose safety risks. Calibration certificates also validate tool accuracy for regulatory audits.

Q: Can digital engineering measuring tools integrate with software, and how does this benefit projects?

A: Yes—tools like laser trackers sync with CAD software to automate data collection, reducing human error in measuring tool usage. This integration allows engineers to generate 3D models directly from field measurements, speeding up processes like architectural design or robotic arm calibration.

Q: What safety considerations should engineers prioritize when using different measuring tools in hazardous environments?

A: When using different measuring tools in settings like oil rigs or chemical plants, engineers must choose explosion-proof models (e.g., intrinsically safe pressure gauges). For high-voltage areas, non-conductive tools like fiberglass tape measures prevent electrical shocks, while thermal imaging cameras help detect hidden hazards without physical contact.

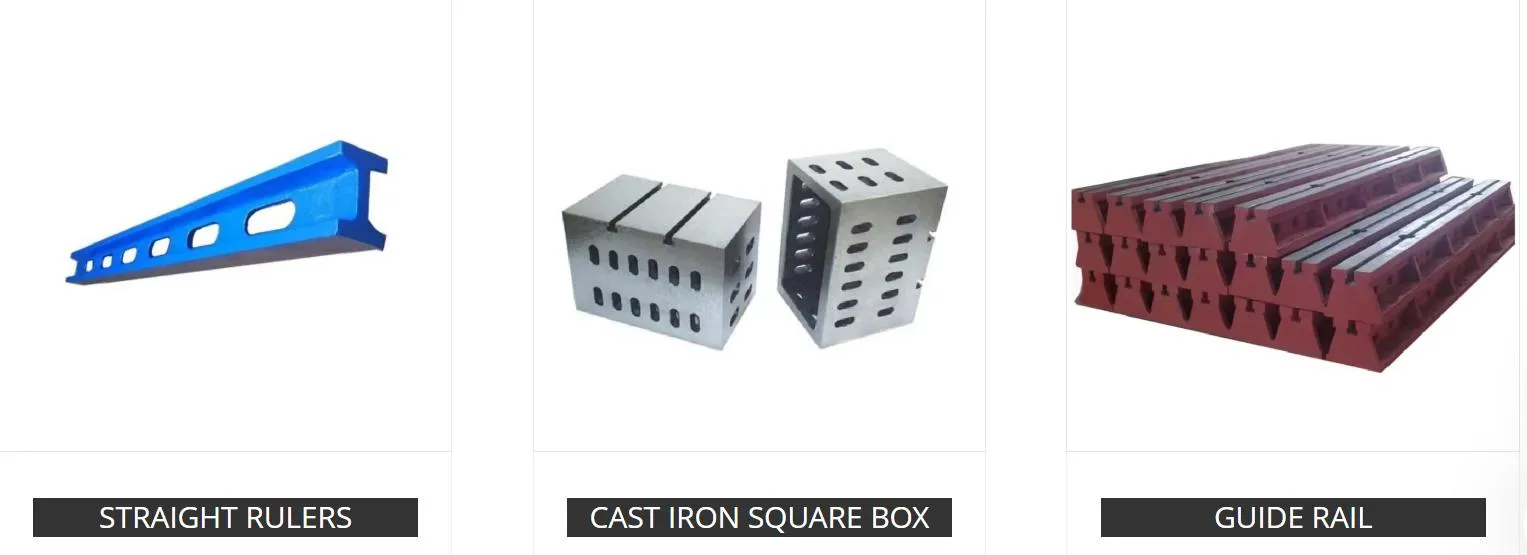

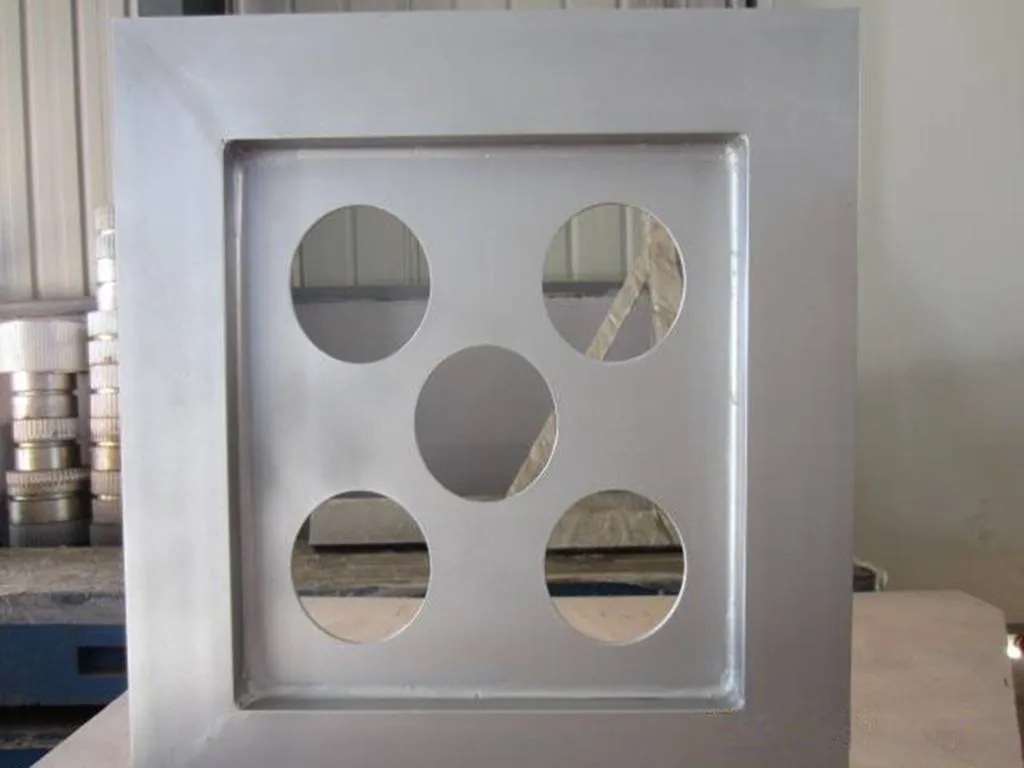

Welcome to Storaen (Cangzhou) International Trading Co. – Where Precision Meets Possibility,Nestled in Botou, China’s crucible of casting excellence, we’re not just manufacturers—we’re architects of industrial innovation. For years, Storaen has forged a legacy of reliability, crafting cast iron welding platforms, measuring tools, gauges, and valves that redefine precision engineering. Our products aren’t just tools; they’re the backbone of global industries, from automotive giants to renewable energy pioneers.

What sets us apart? Botou’s vibrant ecosystem of raw material artisans and technical virtuosos fuels our edge. Every cast iron platform bears the mark of Botou’s 2,000-year casting heritage, while our digital measuring tools blend ancient craftsmanship with cutting-edge tech. We don’t just meet standards—we shatter them, subjecting each product to 27 rigorous quality checks before it bears our name.

But we’re more than a factory. We’re a partner in progress. Whether you need custom valves for deep-sea rigs or anti-corrosion gauges for chemical plants, our team of engineers turns challenges into solutions. Got a wild idea? Bring it on—our R&D lab thrives on the impossible.

Ready to transform your operations? Dive into a world where “good enough” is a dirty word. Visit www.strmachinery.com to explore our precision universe. Let’s build something legendary—together.

-

thread-plug-gauge-our-promise-of-measurement-excellenceबातम्याAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyबातम्याAug.22,2025

-

check-valve-types-for-high-rise-buildingsबातम्याAug.22,2025

-

water-control-valve-for-irrigation-systemsबातम्याAug.22,2025

-

gate-valve-with-soft-seal-technologyबातम्याAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsबातम्याAug.22,2025

संबंधित उत्पादने