फेब्रुवारी . 15, 2025 16:39 Back to list

Granite V-frame Marble V-frame

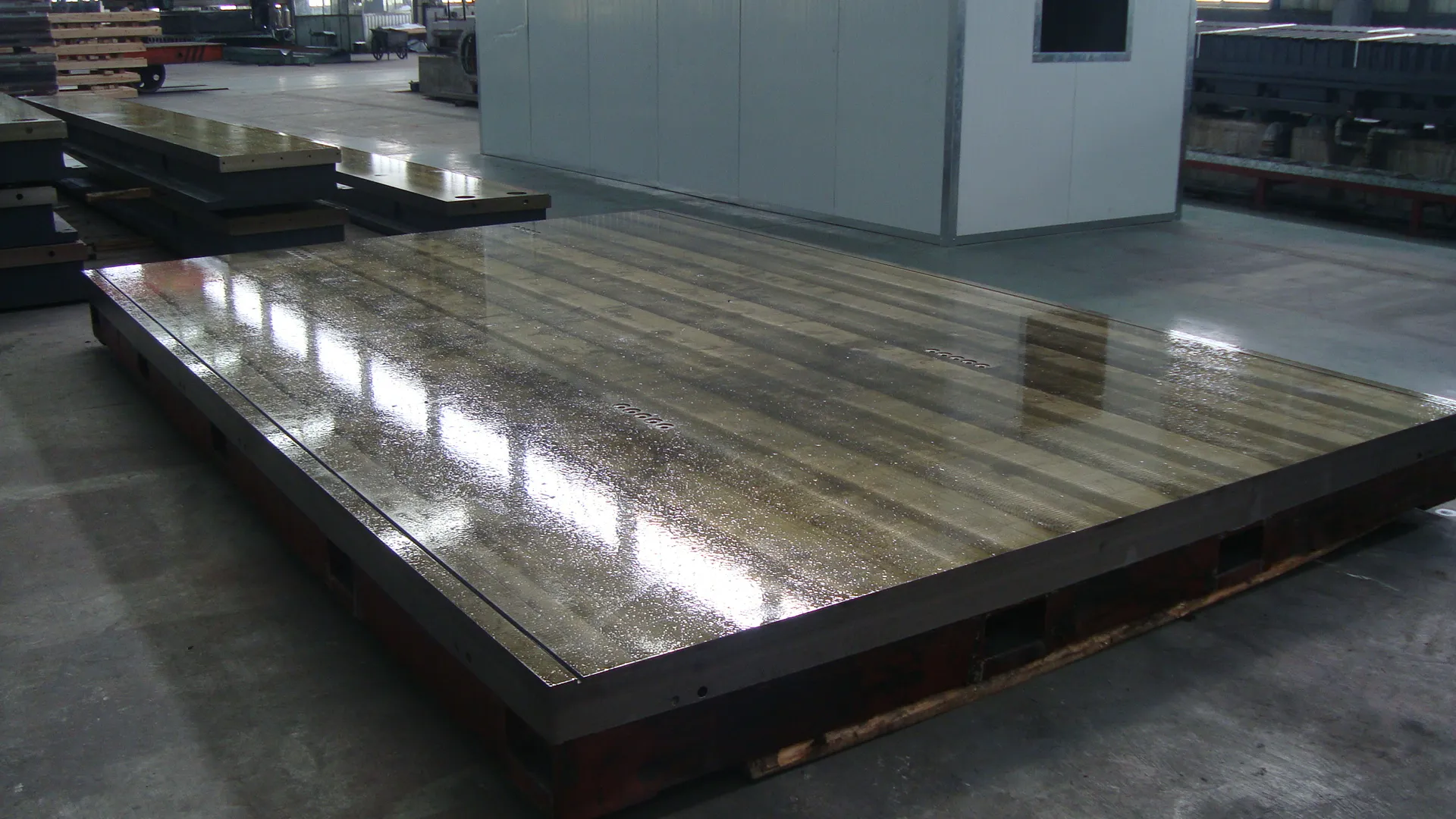

Granite angle plates have long been the cornerstone for precision measurement and setup applications in various industries. As an essential tool in machining, manufacturing, and quality assurance, these plates provide a reliable reference point for inspection and calibration tasks. With the surge in demand for products that guarantee accuracy, the choice of material becomes paramount in selecting an angle plate. Granite, with its inherent properties, stands out as the preferred choice.

Furthermore, granite's resistance to scratching and wear adds to its durability. This resistance mitigates the risk of surface abrasions that could compromise the precision of measurements. As a result, industries where accuracy is non-negotiable, such as aerospace, automotive, and electronics, heavily rely on granite angle plates. Trust in an angle plate is paramount. Companies cannot afford discrepancies in measurement that might lead to product failures or safety hazards. Granite angle plates are subjected to rigorous testing and quality assurance checks before they reach the market. This ensures that each plate meets the specified tolerances and standards required by industry regulations. With certifications from internationally recognized bodies, users can trust in the reliability of their tools. One might wonder about the financial commitment involved in acquiring granite angle plates compared to their metal counterparts. While the initial investment is higher, the long-term benefits in terms of durability, minimal maintenance, and avoidance of costly operational errors provide tangible returns on investment. In cost-sensitive industries, this makes granite an economically sound choice in the long run. For establishments seeking to enhance manufacturing precision, integrating granite angle plates into the workspace is transformative. The assurance of consistency in measurements boosts confidence in product quality, fostering a reputation for excellence. Companies can leverage this accuracy to gain a competitive edge, proving their dedication to quality and precision to clients and stakeholders. In conclusion, the value of granite angle plates extends beyond their function as a mere tool. They represent a blend of natural properties and expert craftsmanship that promises accuracy, durability, and reliability. By prioritizing quality materials and meticulous standards, industries can bolster their measurement processes, ultimately delivering superior products. With the benefits of granite angle plates well-documented and universally acknowledged, they stand as a testament to precision in the realm of industrial measurement tools.

Furthermore, granite's resistance to scratching and wear adds to its durability. This resistance mitigates the risk of surface abrasions that could compromise the precision of measurements. As a result, industries where accuracy is non-negotiable, such as aerospace, automotive, and electronics, heavily rely on granite angle plates. Trust in an angle plate is paramount. Companies cannot afford discrepancies in measurement that might lead to product failures or safety hazards. Granite angle plates are subjected to rigorous testing and quality assurance checks before they reach the market. This ensures that each plate meets the specified tolerances and standards required by industry regulations. With certifications from internationally recognized bodies, users can trust in the reliability of their tools. One might wonder about the financial commitment involved in acquiring granite angle plates compared to their metal counterparts. While the initial investment is higher, the long-term benefits in terms of durability, minimal maintenance, and avoidance of costly operational errors provide tangible returns on investment. In cost-sensitive industries, this makes granite an economically sound choice in the long run. For establishments seeking to enhance manufacturing precision, integrating granite angle plates into the workspace is transformative. The assurance of consistency in measurements boosts confidence in product quality, fostering a reputation for excellence. Companies can leverage this accuracy to gain a competitive edge, proving their dedication to quality and precision to clients and stakeholders. In conclusion, the value of granite angle plates extends beyond their function as a mere tool. They represent a blend of natural properties and expert craftsmanship that promises accuracy, durability, and reliability. By prioritizing quality materials and meticulous standards, industries can bolster their measurement processes, ultimately delivering superior products. With the benefits of granite angle plates well-documented and universally acknowledged, they stand as a testament to precision in the realm of industrial measurement tools.

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS