जून . 10, 2025 10:28 सूचीकडे परत

Choosing the Right Cast Iron Surface Plate for Your Needs

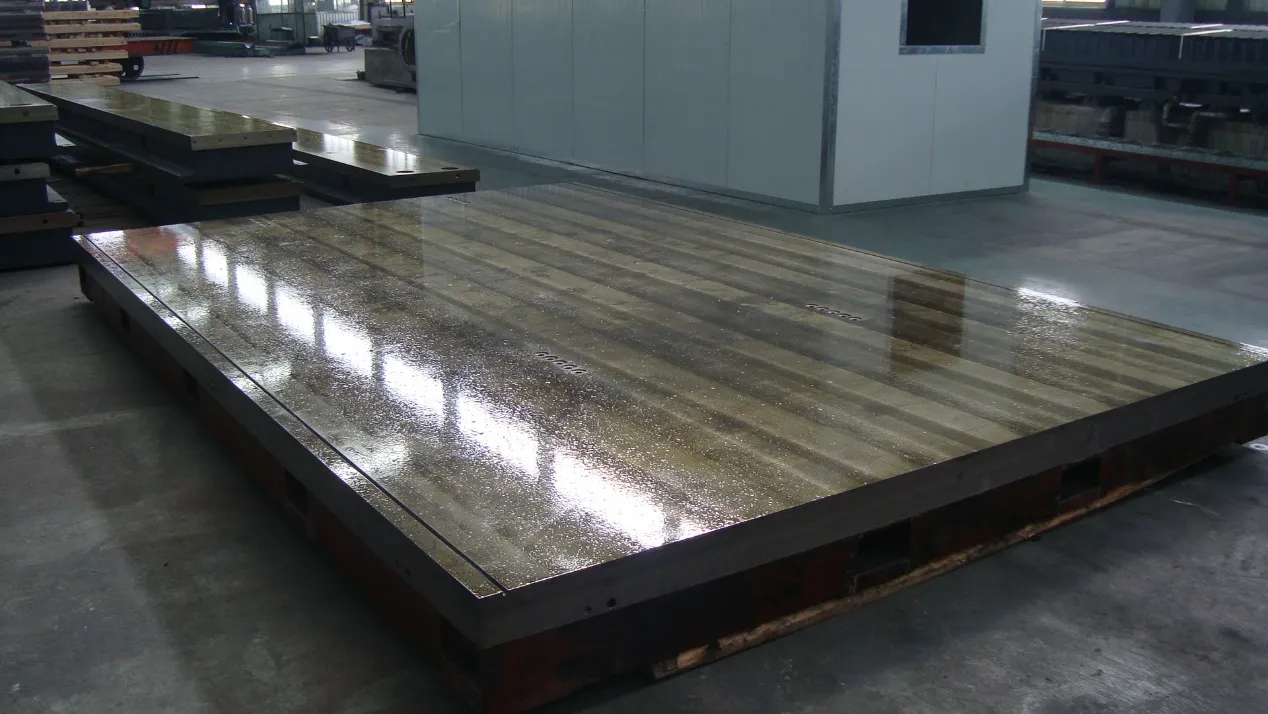

The selection of an appropriate cast iron surface plate represents a critical decision that impacts measurement accuracy, production quality, and long-term operational costs in precision manufacturing environments. As foundational elements in metrology and machining applications, these precision surfaces serve as reliable reference planes for inspection, layout, and assembly work across industries ranging from aerospace to automotive manufacturing.

Understanding the Fundamentals of Cast Iron Surface Plates

Cast iron surface plates derive their exceptional stability and durability from the unique material properties of high-grade cast iron. The granular structure of properly aged cast iron provides natural vibration damping characteristics that make these plates ideal for sensitive measurement applications. When evaluating iron surface plate options, consideration must be given to the plate's intended use environment, required accuracy grade, and anticipated workload. The manufacturing process of these plates involves careful control of metallurgical composition, stress-relieving treatments, and precision scraping to achieve the necessary flatness specifications.

Critical Factors in Selecting the Optimal Iron Surface Plate

Several key considerations guide the selection process for cast iron surface plates, beginning with the required accuracy grade that corresponds to specific flatness tolerances. The plate's thickness directly relates to its stability and resistance to deflection under load, with thicker plates offering greater rigidity for heavy components. Surface treatment options range from traditional hand-scraped finishes to modern machined surfaces, each offering distinct advantages for different applications. Environmental factors including temperature stability, humidity levels, and potential exposure to corrosive elements should inform both the material specification and protective coating selections. The physical dimensions must accommodate both current and anticipated future workpiece sizes while allowing adequate working space around measured components.

Proper Maintenance Practices for Cast Iron Lapping Plates

Maintaining the accuracy and performance of cast iron lapping plates requires adherence to strict care protocols that differ from standard surface plate maintenance. The porous nature of lapping plate surfaces demands particular attention to prevent abrasive particle embedding and cross-contamination between different abrasive grades. Regular resurfacing procedures maintain the plate's geometric accuracy and surface characteristics essential for consistent lapping performance. Proper storage conditions prevent warping or surface damage when plates are not in active use, with careful attention to support points that mimic in-use conditions. Protective coatings may be applied during storage periods to prevent oxidation while ensuring easy return to service when needed.

Emerging Technologies in Cast Iron Surface Plate Manufacturing

Recent advancements in cast iron surface plate production incorporate innovative techniques that enhance performance characteristics. Improved alloy formulations provide better dimensional stability and corrosion resistance while maintaining the vibration damping properties essential for precision measurement applications. Advanced stress-relieving processes utilizing thermal cycling and vibration treatments ensure long-term stability of the cast iron structure. Modern surface finishing techniques achieve flatter reference planes with more consistent surface textures across the entire working area. These technological improvements collectively contribute to extended service life and reduced recalibration frequency for high-precision applications.

Cast Iron Surface Plate FAQS

What determines the lifespan of a cast iron surface plate

The operational lifespan of a cast iron surface plate depends on multiple factors including usage frequency, environmental conditions, maintenance practices, and initial quality. Properly maintained plates in controlled environments can remain serviceable for exceptionally long periods, with periodic rescraping or resurfacing restoring accuracy as needed.

How does a cast iron lapping plate differ from standard granite surfaces

Cast iron lapping plates offer distinct advantages over granite for certain applications due to their metal composition that better matches the thermal expansion characteristics of machined components. The iron surface maintains better abrasive particle retention during lapping operations compared to non-porous granite alternatives.

What protection methods work best for iron surface plate preservation

Effective protection strategies for iron surface plates include regular cleaning with appropriate solvents, application of protective oils or rust inhibitors when not in use, and proper covering during idle periods. Environmental controls maintaining stable temperature and humidity levels significantly contribute to long-term preservation.

When should a cast iron surface plate be recalibrated

Recalibration intervals for cast iron surface plates should be established based on usage intensity and accuracy requirements, with high-precision applications demanding more frequent verification. Visible wear patterns, measurement inconsistencies, or changes in surface appearance typically indicate the need for professional evaluation.

Can cast iron lapping plates be resurfaced after significant wear

Professional refurbishment services can restore cast iron lapping plates through specialized resurfacing processes that recreate the original surface characteristics. The feasibility depends on the extent of wear and the plate's remaining material thickness after resurfacing operations.

-

Precision Manufacturing with Advanced Spline Gauge Designबातम्याJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact Measurementsबातम्याJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 Solutionsबातम्याJul.31,2025

-

High-Performance Gate Valve Wholesaleबातम्याJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision Measurementबातम्याJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk Buyersबातम्याJul.31,2025

संबंधित उत्पादने