12-р сар . 16, 2024 14:15 Back to list

Understanding the Function and Importance of a Check Valve in Fluid Systems

Understanding Check Valves A Key Component in Fluid Systems

In the realm of fluid dynamics, check valves are pivotal components that ensure the efficient and safe operation of various systems. Often taken for granted, these devices play a crucial role in maintaining the intended flow direction of liquids and gases, preventing backflow, and safeguarding equipment from potential damage. This article delves into the functionalities, types, and applications of check valves, highlighting their significance in industrial and residential settings.

What is a Check Valve?

A check valve, also known as a non-return valve or one-way valve, is designed to allow fluid to flow in one direction while preventing backflow. This mechanism is essential in systems where the reverse flow can cause problems, such as contamination, damage to pump systems, or the disruption of operational processes. The basic functional principle of a check valve is relatively simple it utilizes a movable disc or ball that closes when back pressure is detected, thus blocking any attempt of flow reversal.

Types of Check Valves

There are several types of check valves, each suited for different applications and fluid characteristics

1. Swing Check Valve This type features a hinged disc that swings on a pivot. When fluid flows in the intended direction, the disc opens; when backflow occurs, the disc swings shut under its own weight, effectively blocking reverse flow. Swing check valves are commonly used in pipelines and water systems due to their efficiency and reliability.

2. Lift Check Valve Similar to swing check valves, lift check valves employ a disc that lifts off its seat when fluid flows in the desired direction. However, instead of swinging, the disc moves vertically. This type is often used in applications requiring tight sealing and where high velocity is present.

3. Ball Check Valve This design incorporates a ball that sits in a seat at the valve's opening. When fluid flows forward, the ball moves away from the seat, allowing flow. If backpressure occurs, the ball is pushed back into the seat, creating a seal. Ball check valves are praised for their straightforward design and effectiveness in high-pressure applications.

4. Diaphragm Check Valve Utilizing a flexible diaphragm, this valve opens and closes based on pressure differentials. The diaphragm moves with incoming flow and seals against the seat when backflow is detected. These valves are often used in situations requiring sanitary conditions, such as food and beverage processing.

a check valve

Applications of Check Valves

Check valves have a wide range of applications across various industries

- Water and Wastewater Management In municipal water systems, check valves prevent backflow from pipelines, ensuring clean water supply and protecting treatment plants from contamination.

- Oil and Gas In the oil and gas industry, check valves are essential for maintaining pipeline integrity and preventing backflow, which can lead to hazardous situations.

- HVAC Systems In heating, ventilation, and air conditioning systems, check valves help maintain airflow direction, ensuring efficient operation and preventing potential damage to equipment.

- Industrial Processes Many industrial processes rely on check valves to maintain the desired flow direction of chemicals, fluids, or gases, preventing backflow that could disrupt production or lead to safety hazards.

Importance of Check Valves

The significance of check valves extends beyond mere functionality; they are integral to ensuring safety and efficiency in fluid systems. By preventing backflow, these valves protect equipment from reverse pressure that could lead to mechanical failures or contamination. They also contribute to energy efficiency by maintaining optimal flow conditions, which can reduce operational costs.

In conclusion, check valves are unsung heroes in the world of fluid dynamics, offering a simple yet effective solution to a complex problem—ensuring that fluids flow where they need to go without the risk of backtrack. Understanding the different types and applications of check valves can help engineers and operators design safer and more efficient systems. As technology evolves, the design and application of check valves will continue to advance, further enhancing their vital role in modern fluid management.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

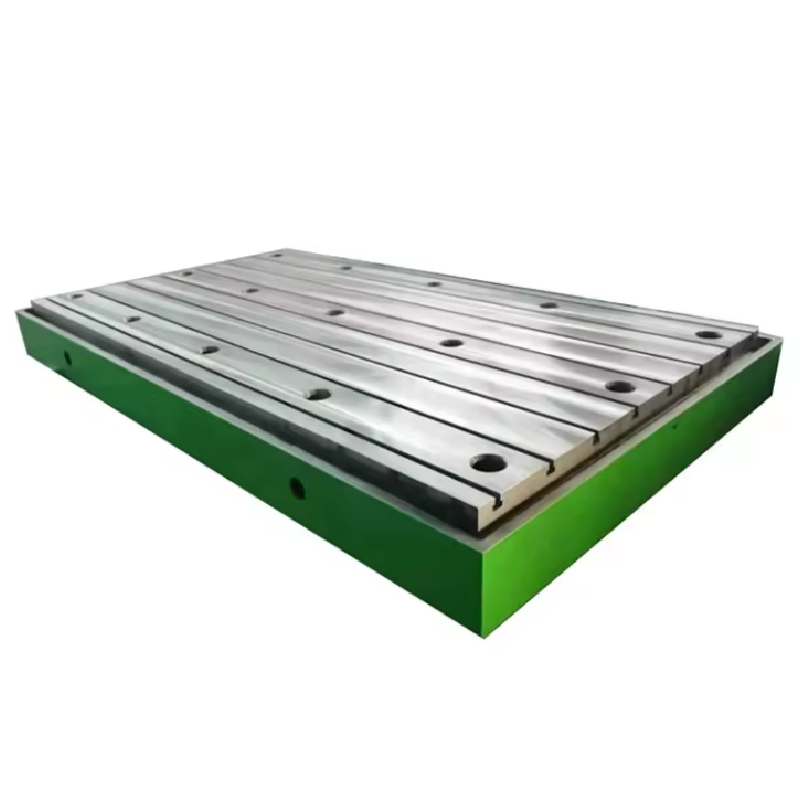

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS