ഫെബ്രു . 19, 2025 09:07 Back to list

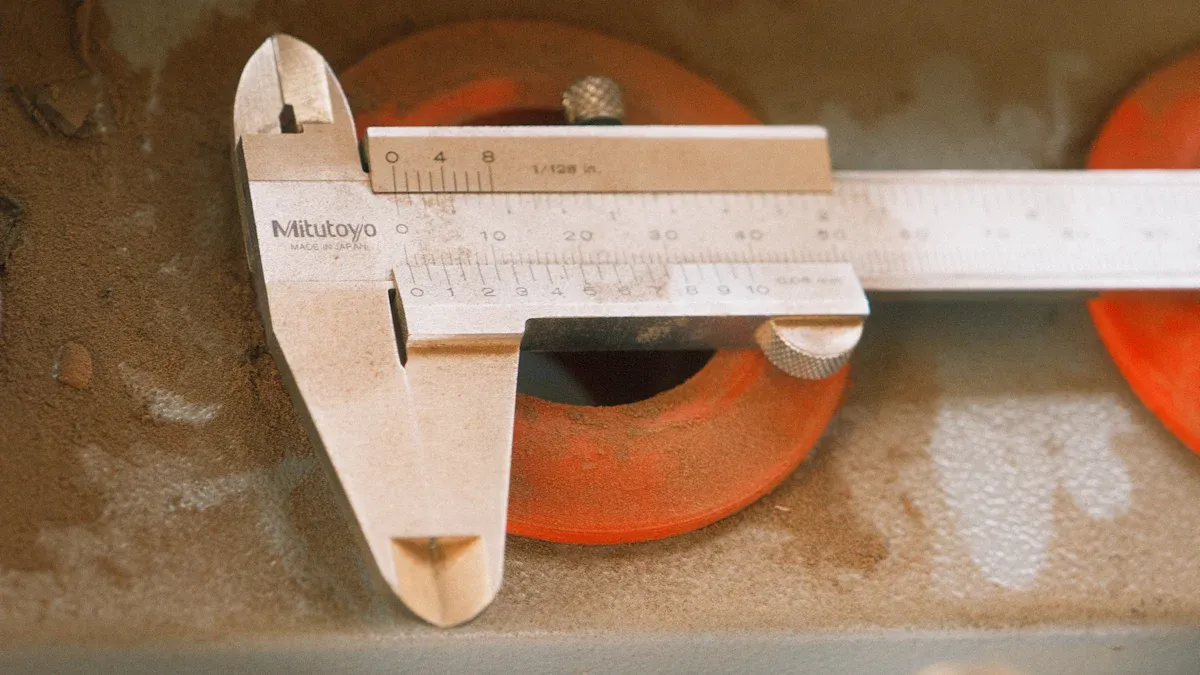

Magnetic V Block

Magnetic V blocks are indispensable tools in the world of precision manufacturing and machining. These bench-top devices are essential for holding cylindrical workpieces in place during inspection, marking, or machining processes. The price of magnetic V blocks can vary significantly based on several factors including material quality, size, precision level, and brand reputation.

From a professional standpoint, while opting for well-known brands may seem an obvious choice, evaluating lesser-known brands can occasionally yield cost-effective yet high-quality alternatives. This requires careful assessment of user reviews, third-party evaluations, and direct experience within workshop settings. Trustworthiness is a key factor when considering vendors of magnetic V blocks. Reliable suppliers will often provide detailed specifications, customer testimonials, and comprehensive warranties, ensuring that the customer can rely on the product's performance. Engaging with online forums, industry networks, and market research can further aid in identifying reputable sellers, ensuring that the price paid reflects a sound investment. Over the years, I've also observed that some suppliers offer considerable discounts during trade shows or as part of bulk purchase deals. This can be an excellent opportunity for businesses to acquire high-grade magnetic V blocks at reduced prices, optimizing budget allocations without compromising on quality. Continuous advancements in technology have introduced digital versions of these classic tools, which integrate digital readouts for enhanced accuracy. These digital magnetic V blocks, while generally more expensive, offer significant advantages in modern precision machining environments, providing real-time data and reducing manual measurement errors. In conclusion, the price of magnetic V blocks is influenced by multiple factors, each impacting the overall utility and longevity of the tool. Professionals in the field should thoughtfully consider all aspects—from precision needs and durability to brand reputation and vendor trustworthiness—when making a purchase. By striking the right balance between price and quality, businesses can ensure they equip their workshops with reliable tools that enhance productivity and meet stringent quality standards.

From a professional standpoint, while opting for well-known brands may seem an obvious choice, evaluating lesser-known brands can occasionally yield cost-effective yet high-quality alternatives. This requires careful assessment of user reviews, third-party evaluations, and direct experience within workshop settings. Trustworthiness is a key factor when considering vendors of magnetic V blocks. Reliable suppliers will often provide detailed specifications, customer testimonials, and comprehensive warranties, ensuring that the customer can rely on the product's performance. Engaging with online forums, industry networks, and market research can further aid in identifying reputable sellers, ensuring that the price paid reflects a sound investment. Over the years, I've also observed that some suppliers offer considerable discounts during trade shows or as part of bulk purchase deals. This can be an excellent opportunity for businesses to acquire high-grade magnetic V blocks at reduced prices, optimizing budget allocations without compromising on quality. Continuous advancements in technology have introduced digital versions of these classic tools, which integrate digital readouts for enhanced accuracy. These digital magnetic V blocks, while generally more expensive, offer significant advantages in modern precision machining environments, providing real-time data and reducing manual measurement errors. In conclusion, the price of magnetic V blocks is influenced by multiple factors, each impacting the overall utility and longevity of the tool. Professionals in the field should thoughtfully consider all aspects—from precision needs and durability to brand reputation and vendor trustworthiness—when making a purchase. By striking the right balance between price and quality, businesses can ensure they equip their workshops with reliable tools that enhance productivity and meet stringent quality standards.

Next:

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS