ഡിസം . 17, 2024 10:41 Back to list

internal taper gauge

Understanding Internal Taper Gauges A Comprehensive Overview

Internal taper gauges play a critical role in various industries, providing a precise method for measuring internal diameters, angles, and tapers of holes. These tools are essential in manufacturing, automotive, aerospace, and other fields where accuracy in dimensions is paramount. This article aims to elaborate on the functions, types, and significance of internal taper gauges in ensuring quality and precision in engineering applications.

What is an Internal Taper Gauge?

An internal taper gauge is a specialized tool designed to measure the internal taper or angle of boreholes. Unlike standard gauges, which may only measure straight diameters, taper gauges can evaluate how the diameter of a hole changes along its depth. This feature is particularly important when working with components that require a specific taper for fitting purposes, such as machined parts that need to align perfectly when assembled.

Types of Internal Taper Gauges

There are several types of internal taper gauges, each suited for specific applications

1. Fixed Angle Taper Gauges These gauges feature a set angle that is commonly used in industries. They are straightforward to use and provide quick measurements. However, they are limited to specific angles.

2. Adjustable Taper Gauges More versatile, these gauges allow for adjustments in the angle depending on the required measurement. They typically have a set screw mechanism that can be manipulated to achieve the desired taper angle.

3. Digital Internal Taper Gauges Utilizing digital technology, these gauges provide a fast and accurate readout of taper measurements. They often feature enhanced functionalities such as data logging, making them suitable for advanced manufacturing setups.

4. Dial Indicators with Taper Gauge Attachments These tools allow users to measure tapers while also providing a visual display of the measurement on a dial. The combination of features offers both versatility and precision in assessing internal dimensions.

Importance of Internal Taper Gauges

1. Precision and Consistency The primary purpose of internal taper gauges is to ensure precision in manufacturing processes. Accuracy in measurements leads to better fitting components, reducing the risk of production errors and increasing the quality of the final product.

internal taper gauge

2. Quality Control Taper gauges are integral to quality control in factory settings. By regularly checking internal tapers, manufacturers can ensure that their products meet strict specifications and tolerances. This capability helps in mitigating defects and enhancing reliability.

3. Time Efficiency With easy-to-use designs, internal taper gauges can save time during the measurement process. Their ability to quickly deliver accurate results enables manufacturers to streamline workflows and increase productivity.

4. Versatility Across Industries Whether in automotive engineering, aerospace design, or heavy machinery production, internal taper gauges are applicable across various domains. Their ability to provide specific measurements helps industries adapt to diverse operational standards and requirements.

Best Practices for Using Internal Taper Gauges

To ensure accurate measurements and extend the lifespan of internal taper gauges, consider the following best practices

- Regular Calibration Ensure that gauges are regularly calibrated to maintain accuracy in measurements. This step is crucial in industries where tolerances are critical.

- Proper Handling and Storage Store gauges in protective cases to prevent damage from physical impacts or environmental factors such as moisture and dust.

- Training and Awareness Operators should be adequately trained in the use of internal taper gauges to minimize the chances of human error during measurements.

- Routine Inspection Regularly inspect taper gauges for wear and tear to ensure they remain in optimal condition for precise measurement tasks.

Conclusion

Internal taper gauges are indispensable tools in the precision-driven landscape of modern manufacturing. Their ability to measure internal tapers with high accuracy supports quality control and enhances the overall effectiveness of production processes. Investing in high-quality internal taper gauges and adhering to best practices can lead to improved product consistency and reliability, ultimately driving success in competitive markets. As industries continue to evolve, the significance of these gauges will only grow, cementing their role in the future of engineering and manufacturing.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

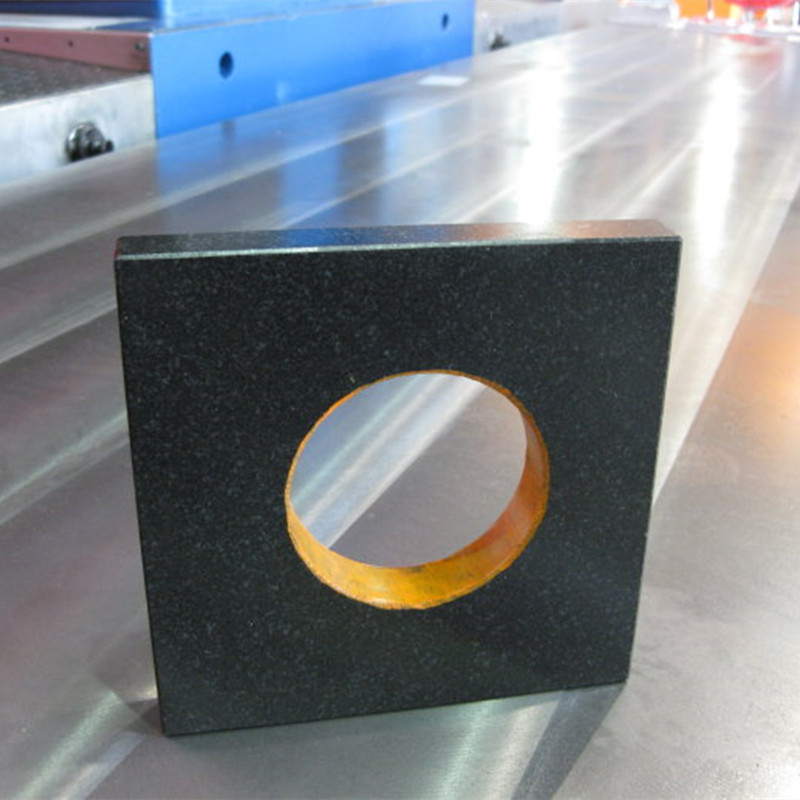

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS