ഡിസം . 29, 2024 19:25 Back to list

Granite Surface Plate Calibration Techniques for Precision Measurement and Quality Assurance

Calibration of Granite Surface Plates An Essential Practice for Precision Engineering

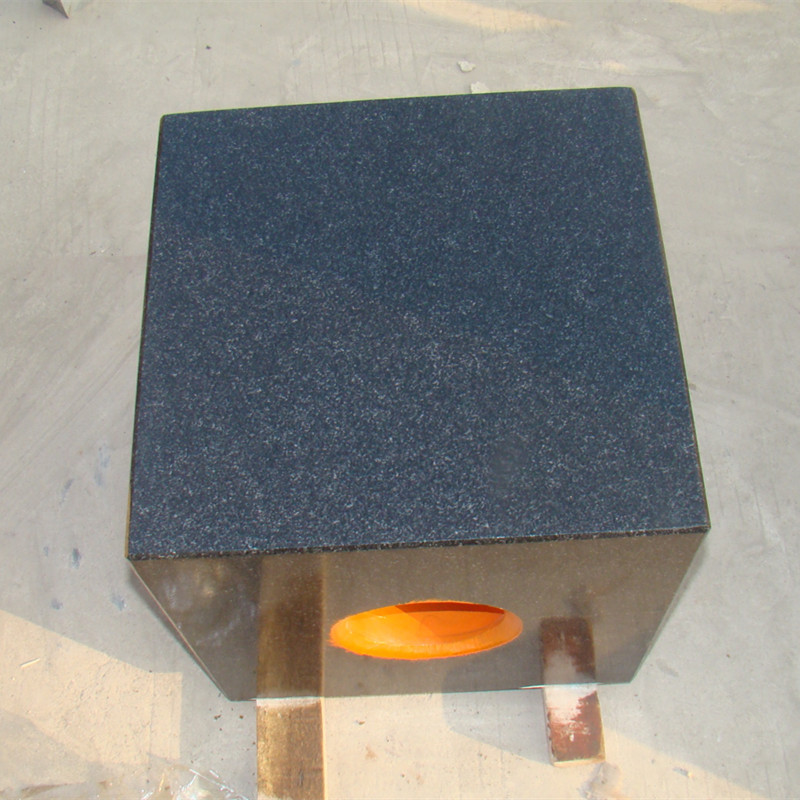

Granite surface plates are fundamental tools in precision engineering, serving as stable reference surfaces for measuring, inspecting, and fabricating components. The importance of calibration for these plates cannot be overstated, as it directly influences the accuracy and reliability of measurements taken in various industrial and scientific applications.

Granite, with its exceptional stability, low thermal expansion, and resistance to wear, is the material of choice for surface plates. However, even granite plates can develop imperfections over time due to usage, environmental factors, or manufacturing inconsistencies. Therefore, regular calibration is necessary to ensure that surface plates maintain their designed geometric properties and provide the precision required in critical applications.

The Calibration Process

The calibration of granite surface plates typically involves a few key steps

1. Visual Inspection Before initiating the calibration, a thorough visual inspection is performed to identify any visible signs of wear, cracks, or chips. Surface contaminants, such as dust or oil, are also cleaned off to prevent interference with the measurement process.

2. Leveling The plate is leveled to ensure that the calibration equipment operates under optimal conditions. A level surface is essential for accurate measurements, as even minor inclines can lead to significant discrepancies in results.

3. Measurement with Precision Instruments Calibration is carried out using precision instruments such as dial gauges, laser interferometers, or coordinate measuring machines (CMMs). These tools accurately measure the flatness and other geometric properties of the surface plate. The data collected is compared against the manufacturer's specifications or established industry standards.

4. Adjustment and Rectification If the calibration results reveal that the surface plate falls outside acceptable tolerance levels, adjustments may be necessary. This can include grinding specific areas or using specialized equipment to correctSurface flatness.

granite surface plate calibration

5. Certification Once calibration is successfully completed, a certification document is usually generated. This serves as a record of the calibration process and confirms that the granite surface plate meets the necessary standards for precision work.

Importance of Calibration

Regular calibration of granite surface plates is crucial for a variety of reasons

- Accuracy In industries such as aerospace, automotive, and manufacturing, even a slight inaccuracy in measurements can lead to significant defects in products. Regularly calibrated surface plates help ensure that measurements taken are as accurate as possible.

- Quality Control Calibration is an integral part of quality assurance protocols. Using calibrated tools and equipment fosters consistency and reliability in production, which is vital for meeting regulatory and client standards.

- Longevity of Equipment Proper calibration and maintenance extend the lifespan of granite surface plates. By regularly checking and addressing any issues, companies can avoid costly replacements and disruptions in workflow.

- Safety In some sectors, precise measurements directly impact safety. Inaccuracies can lead to equipment failures or accidents, particularly in high-stakes industries like manufacturing and aviation.

Conclusion

Calibration of granite surface plates is an essential procedure that supports the integrity of precision engineering practices. By ensuring that these critical tools maintain their accuracy, companies can uphold quality standards, enhance operational efficiency, and ensure safety in their products. As technology evolves and the demand for precision continues to rise, the role of calibration will remain a cornerstone in the field of metrology, driving advancements and fostering trust in measurement processes.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS