നവം . 27, 2024 05:52 Back to list

Exploring the Features and Applications of Globe Gate Valves in Industrial Settings

Understanding Globe Gate Valves Design, Applications, and Benefits

Globe gate valves are critical components in various industrial applications, used primarily to control fluid flow. Understanding their design, functionality, and advantages can help engineers and operators make informed decisions when selecting valves for their systems.

Design and Structure

Globe gate valves are characterized by their distinct shape, which resembles a globe, and their internal disc mechanism that helps to regulate flow. These valves typically consist of a body, a bonnet, a stem, and a disk. The body is designed to withstand high pressures and is usually made from durable materials such as stainless steel, brass, or cast iron. The bonnet houses the stem and provides an accessible area for maintenance and repairs.

One of the standout features of a globe gate valve is its disk. Unlike other valves, the disk in a globe gate valve is positioned perpendicular to the flow of the fluid, allowing for precise control over the flow rate. This design enables the valve to provide a tight seal, minimizing leakage and ensuring that the system operates efficiently.

Functionality

Globe gate valves function by using a rotating stem that raises or lowers the disk to open or close the flow path. When the stem is turned, the disk moves vertically, allowing or obstructing the flow of the medium. This action enables operators to adjust the flow rate accurately, making globe gate valves ideal for applications that require precise control.

Due to their design, globe gate valves are more effective at regulating flow than other types of valves, such as gate or ball valves. They can handle throttling operations well, which is essential in many industrial processes where the flow of liquids and gases must be carefully managed.

Applications

globe gate valve

Globe gate valves are widely used in various industries, including oil and gas, water treatment, power generation, and chemical processing. In the oil and gas industry, for instance, they regulate the flow of crude oil and natural gas in pipelines. In water treatment facilities, they control the flow of water during filtration and purification processes.

Moreover, globe gate valves are crucial in power plants, where they manage steam and water flow in different systems

. Their ability to withstand high temperatures and pressures makes them suitable for these demanding environments. In chemical processing, they help control the flow of corrosive and non-corrosive fluids, ensuring safety and efficiency in operations.Advantages

The advantages of using globe gate valves are manifold. First and foremost, their ability to provide precise control over fluid flow makes them a preferred choice in systems where regulation is essential. They also offer excellent sealing capabilities, minimizing the risk of leaks that can lead to safety hazards or environmental concerns.

Additionally, globe gate valves have a robust design that allows them to operate effectively under high-pressure and high-temperature conditions. This durability often translates into a longer service life, reducing the need for frequent replacements and maintenance.

Another significant benefit is the ease of operation and maintenance. Since the bonnet of a globe gate valve is designed for accessibility, routine inspections and repairs can be carried out with minimal downtime. This feature is especially valuable in industrial settings where maximizing uptime is critical for productivity.

Conclusion

In summary, globe gate valves are essential for fluid control in various industrial applications. Their unique design, combined with the ability to regulate flow accurately and efficiently, makes them indispensable in many systems. As industries continue to evolve and demand greater efficiency and safety, understanding and utilizing globe gate valves will remain a critical component of successful fluid management strategies. Whether you're in oil and gas, water treatment, or any other sector requiring precise fluid control, globe gate valves should be a key consideration in the design and operation of your systems.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

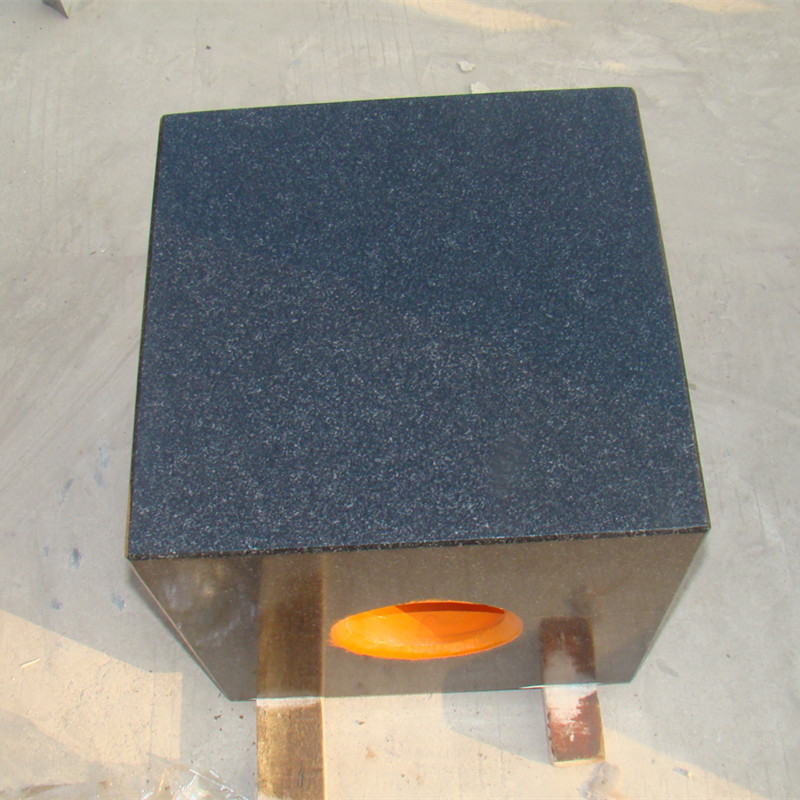

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS