ഡിസം . 25, 2024 10:54 Back to list

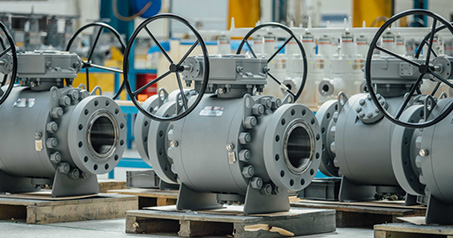

Durable Ductile Iron Knife Gate Valve for Reliable Fluid Control Applications

The Ductile Iron Knife Gate Valve A Comprehensive Overview

In the realm of industrial fluid control, the knife gate valve has earned its rightful place as a robust solution for managing the flow of liquids and slurries in various applications. Among the materials used in the construction of these valves, ductile iron stands out due to its remarkable properties and versatility. This article delves into the characteristics, advantages, applications, and maintenance of ductile iron knife gate valves, providing a comprehensive overview for engineers and industry professionals.

What is a Knife Gate Valve?

A knife gate valve is a type of valve specifically designed for on-off service in applications where the media being transported may contain solid particles or might be abrasive in nature. The defining feature of this valve is its blade-like gate that can easily slice through the material, allowing for efficient flow control. Knife gate valves are typically used in industries such as wastewater treatment, pulp and paper, mining, and agriculture.

The Role of Ductile Iron

Ductile iron, also known as spheroidal graphite iron, is an iron alloy characterized by its improved ductility, strength, and shock resistance when compared to traditional cast iron. This material is produced by adding small amounts of alloying elements, such as magnesium, to the molten iron, which alters the form of graphite present in the metal. The resulting microstructure imparts several valuable properties

1. Enhanced Strength Ductile iron exhibits a higher tensile strength compared to conventional cast iron, making it suitable for high-pressure applications.

2. Improved Ductility The material can withstand deformation without fracturing, which is crucial in dynamic environments where stress may vary.

3. Corrosion Resistance While ductile iron is more prone to corrosion than some alloys, advancements in coatings and surface treatments can significantly enhance its durability against corrosive substances.

4. Cost-Effective Ductile iron is generally less expensive than stainless steel or high alloy materials, providing a cost-effective solution for various applications.

Advantages of Ductile Iron Knife Gate Valves

The integration of ductile iron in knife gate valve manufacturing offers numerous advantages

- Long Service Life The combination of strength and ductility contributes to the valve's durability, enabling it to withstand harsh conditions and extend its operational lifespan.

- Efficient Flow Control The design of the knife gate valve allows for tight shut-off capabilities, minimizing leaks and maintaining system integrity.

- Versatility Ductile iron knife gate valves can be adapted for a variety of industries and media types, from water to slurry and chemical applications

.ductile iron knife gate valve

- Ease of Maintenance The simple design of these valves facilitates easier maintenance and repairs, reducing downtime and servicing costs.

Applications

Ductile iron knife gate valves are used across various sectors, including

- Wastewater Treatment These valves are essential in managing the flow of sewage and sludge, ensuring efficient treatment processes.

- Pulp and Paper Industry They control the flow of pulp, water, and chemicals, contributing to the production of paper and cardboard.

- Mining Operations The robust nature of ductile iron valves makes them suitable for handling slurries and other abrasive materials in mining.

- Agricultural Systems In irrigation and drainage systems, knife gate valves help regulate water flow effectively.

Maintenance Tips

To ensure optimal performance and longevity of ductile iron knife gate valves, regular maintenance is essential

1. Inspection Regularly check for signs of wear, corrosion, or damage. Early detection of issues can prevent costly repairs.

2. Lubrication Apply appropriate lubricants to moving parts to reduce friction and wear.

3. Cleaning Keep the valve and surrounding area clean to prevent buildup of debris, which may impede operation.

4. Replacement of Seals and Gaskets Periodically inspect and replace seals and gaskets to maintain a proper seal and prevent leaks.

Conclusion

Ductile iron knife gate valves combine strength, durability, and cost-effectiveness, making them an ideal choice for a wide range of industrial applications. With their unique design and material properties, these valves not only provide reliable flow control but also help industries optimize their operations. Understanding their advantages and maintenance needs can significantly enhance their performance and lifespan, ensuring that the fluid management systems they serve operate efficiently and effectively.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS