ഡിസം . 09, 2024 18:25 Back to list

Cylinder Bore Measurement Tool for Accurate Engine Performance Testing and Maintenance

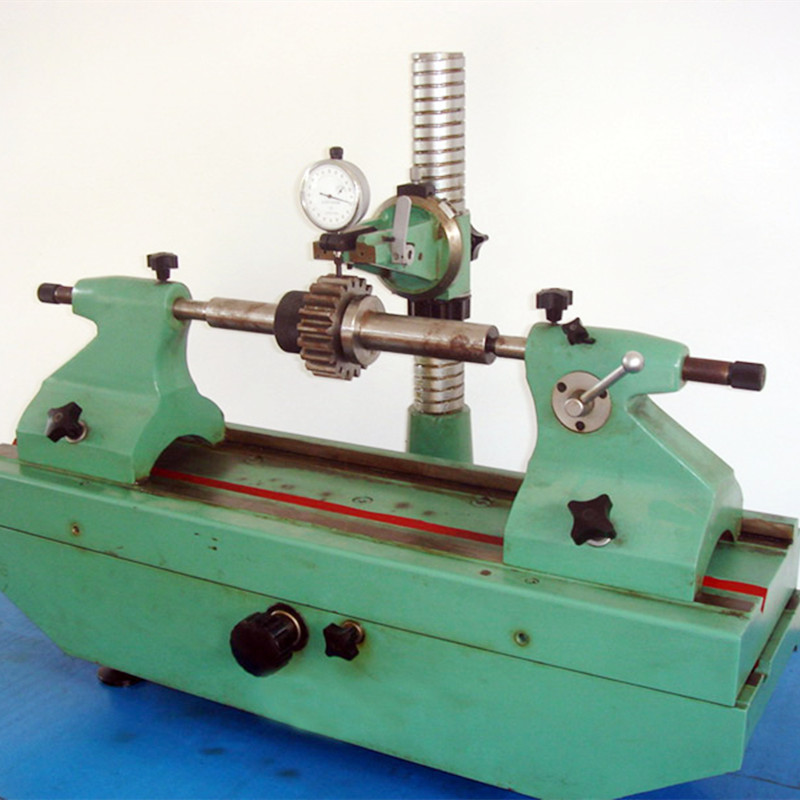

Understanding the Cylinder Bore Gauge An Essential Tool for Precision Measurement

In the world of engineering and automotive maintenance, precision is paramount. One of the invaluable tools that mechanics and engineers rely on for ensuring accuracy in cylindrical measurements is the cylinder bore gauge. This instrument plays an essential role in measuring the diameter of a cylinder, particularly in engines, where maintaining the correct specifications is crucial for optimal performance.

What is a Cylinder Bore Gauge?

A cylinder bore gauge, also known as a bore micrometer, is a measuring instrument specifically designed to measure the internal diameter of a cylindrical object. It typically consists of two main parts a dial gauge and a set of expandable arms or probes that can be adjusted to fit the width of the bore being measured. The dial gauge displays the measurement, allowing users to assess whether the bore is within the specified tolerance levels.

How Does it Work?

Using a cylinder bore gauge involves a few critical steps

. First, the user must ensure that the instrument is calibrated correctly. Calibration is crucial because even minor discrepancies in measurement can lead to significant issues in engine performance, including poor sealing and reduced efficiency.Once calibrated, the bore gauge is inserted into the cylinder. The expandable arms are then adjusted outward until they make contact with the walls of the bore. The user rotates the tool to obtain measurements at different points around the circumference of the cylinder. This step is vital since any wear or irregularities in the bore can lead to uneven measurements. Finally, the reading from the dial gauge will indicate the internal diameter, allowing the technician to compare the measurement against the engine specifications.

cylinder bore gauge

The Importance of Accurate Measurements

Accurate measurements of the cylinder bore are crucial for several reasons. Firstly, engines operate under intense conditions, and even slight deviations can affect performance. If the bore is too large, it may lead to poor compression and loss of power. Conversely, if the bore is too small, it can cause excessive wear on the piston and rings, ultimately leading to engine failure.

Secondly, proper bore measurements are pivotal during the process of engine rebuilding or overhauling. When worn engine components are replaced, it's vital to ensure that the new parts fit correctly. A poorly measured bore can lead to inadequate sealing, increased oil consumption, and reduced engine life.

Maintenance and Usage Considerations

To maximize the effectiveness of a cylinder bore gauge, regular maintenance is necessary. Keeping the instrument clean and free from debris will help maintain accuracy. After each use, it's advisable to wipe down the surface, ensuring that no oil or dirt remains that could skew future measurements. Additionally, users should handle the gauge with care, as dropping it or subjecting it to harsh conditions can derail its precision.

Conclusion

In conclusion, a cylinder bore gauge is an indispensable tool for engineers and automotive professionals. Its ability to provide precise measurements makes it crucial in maintaining engine performance and longevity. By ensuring that their instruments are calibrated, properly maintained, and used correctly, technicians can enhance the accuracy of their work and ultimately contribute to the efficiency of the vehicles they service. As technology continues to advance, the cylinder bore gauge and its counterparts will remain at the forefront of precision measurement in the industry, ensuring that engines run smoothly and efficiently for years to come.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS