ഡിസം . 10, 2024 18:02 Back to list

cast iron inspection table

Understanding the Importance of Cast Iron Inspection Tables

Cast iron is a popular material used in a variety of applications, including construction, automotive components, cookware, and more. Its properties, such as excellent castability, durability, and wear resistance, make it a top choice for many manufacturers. However, like all materials, cast iron can have defects and irregularities that may affect its performance. Therefore, thorough inspection is critical to ensure quality and safety. One of the most effective ways of evaluating cast iron components is through the use of inspection tables.

What is a Cast Iron Inspection Table?

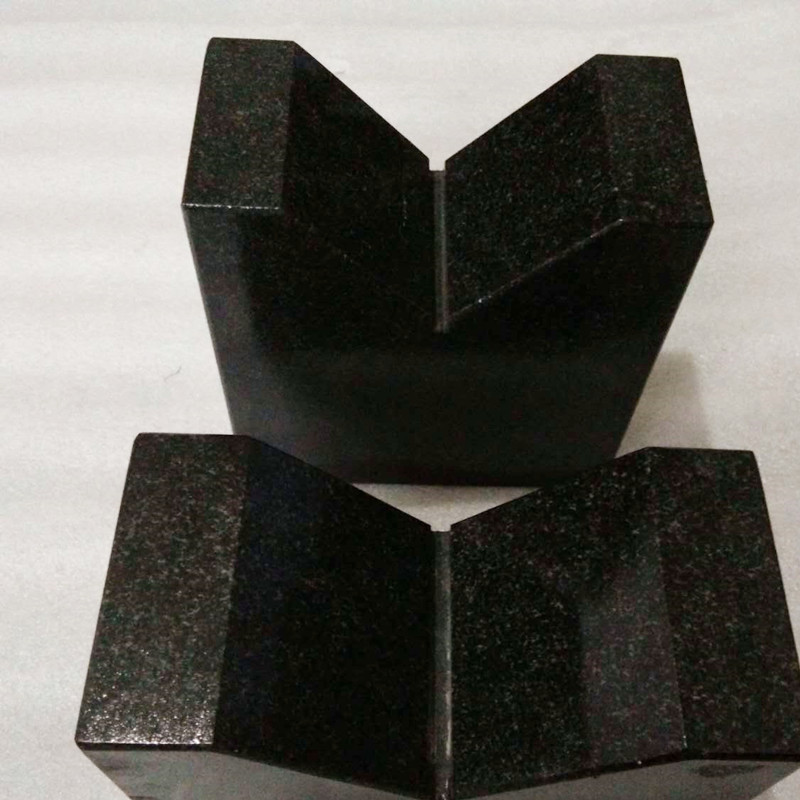

A cast iron inspection table is a finely machined flat surface used for precision measurement and inspection of components made from cast iron and other materials. These tables are designed to provide an accurate reference plane, enabling manufacturers and inspectors to effectively assess various characteristics of the components, including flatness, straightness, and overall geometric integrity.

Why Use Cast Iron Inspection Tables?

1. Precision Measurement The primary advantage of a cast iron inspection table is its ability to provide a highly accurate measurement reference. The surface is machined to a high degree of flatness, allowing for precise alignment of the workpiece. This is essential for detecting even the smallest deviations or irregularities in the component being inspected.

2. Durability and Stability Cast iron is known for its strength and stability, which makes inspection tables resistant to deformation over time. Unlike other materials that may warp or degrade, cast iron maintains its dimensional integrity under varying environmental conditions. This is crucial for maintaining accuracy during inspections.

3. Versatility Cast iron inspection tables can be used for various types of inspections, including dimensional, visual, and functional tests. They are adaptable for different applications, from inspecting large machinery parts to smaller, intricate components.

4. Cost Efficiency Although the initial investment in a cast iron inspection table may be higher than other materials, their longevity and durability contribute to a long-term cost reduction. The need for frequent replacements or repairs is diminished, leading to savings for manufacturers over time.

cast iron inspection table

5. Maintenance of Tolerances For manufacturers working in industries with stringent regulatory requirements, maintaining tight tolerances is essential. Using a cast iron inspection table ensures that all components meet the necessary standards before being deployed in the market. This not only boosts quality assurance but also enhances customer satisfaction.

Implementing Inspection Procedures

To effectively utilize a cast iron inspection table, manufacturers should establish clear guidelines and procedures for inspections. Here are some recommended practices

- Calibration Regularly calibrate the inspection table to ensure that its accuracy is maintained over time. Calibration should be done in accordance with industry standards and using certified measurement tools.

- Cleaning Keep the table surface clean and free from debris. Contaminants can affect measurement accuracy, leading to misinterpretations during the inspection process.

- Proper Handling Train inspection personnel to handle components with care. Avoid dropping or mishandling the parts before placing them on the inspection table, as this could introduce defects that may not have been present initially.

- Documentation Maintain detailed records of inspections, including the specific measurements taken and any findings. This documentation is valuable for quality control processes and can be used for audits or compliance with regulations.

Conclusion

In summary, cast iron inspection tables are an indispensable tool in the manufacturing process. Their precision, durability, and versatility provide a reliable means for evaluating the quality of cast iron components. By implementing rigorous inspection procedures and utilizing these tables effectively, manufacturers can ensure that their products meet the highest quality standards, ultimately leading to enhanced performance, safety, and customer satisfaction. The investment in cast iron inspection tables is not just an expense, but a strategic decision that can significantly elevate the quality assurance processes of any manufacturing operation.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS