നവം . 11, 2024 22:20 Back to list

24 globe valve

Understanding the 24% Globe Valve Design, Functionality, and Applications

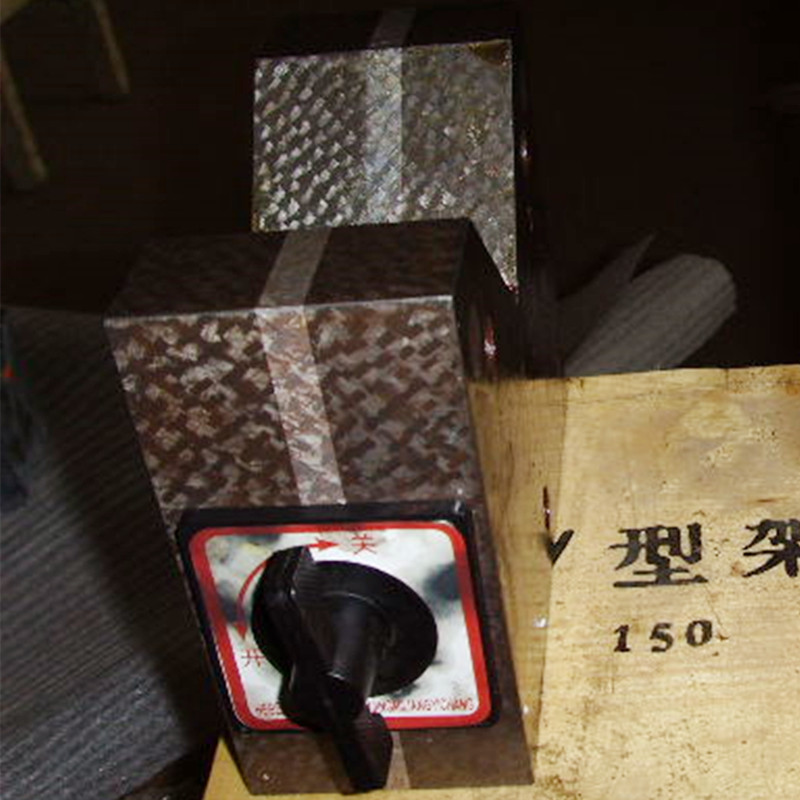

The 24% globe valve is a critical component in various industrial applications, playing a vital role in flow regulation within piping systems. This type of valve is renowned for its ability to control the flow of fluids with a significant degree of precision, making it an essential choice across different sectors, including oil and gas, water treatment, and chemical processing.

Design Characteristics

A globe valve, in general, has a spherical body with an internal baffle that allows for the regulation of flow through the valve. The 24% designation typically refers to a specific size or dimension that is optimal for certain applications. The design of the valve features a movable disk that sits atop a stationary ring seat, which allows for fine control over the flow of fluid. This design is particularly useful in applications where the valve is required to throttle the flow, as it provides a longer seat-to-disk contact area, thus reducing the risk of wear.

The globe valve also features various materials of construction, including stainless steel, brass, and bronze, allowing for utilization in different environments and conditions. The choice of material is crucial as it determines the valve’s resistance to corrosion, pressure, and temperature variations.

Functionality

One of the main advantages of the globe valve is its ability to provide excellent flow control. Unlike gate valves, which are primarily designed for full flow (open or closed), globe valves can effectively control the rate of flow. When adjusted, the disc moves up and down inside the seat, thus altering the size of the opening and allowing for precise flow adjustments. This feature makes the globe valve highly suitable for throttling applications.

24 globe valve

The 24% globe valve is often equipped with a handwheel or actuator that facilitates easy operation. Additionally, as the valve is in service, it can be closed tightly to prevent leakage, which is an important characteristic in maintaining system integrity and safety.

Applications

The versatile nature of the 24% globe valve allows it to be used in a multitude of settings. In the oil and gas industry, they are often employed to manage flows within pipelines and storage tanks. Similarly, in water treatment facilities, globe valves regulate the flow rates of water during treatment and distribution processes.

In the chemical processing industry, the ability to control flow rates precisely means that globe valves are essential in reactors and heat exchangers, where management of material input and output is crucial for effective processing. Furthermore, their robust construction makes them suitable for handling a wide range of temperatures and pressures, further broadening their application scope.

Conclusion

In conclusion, the 24% globe valve is a sophisticated device that combines effective flow control with a reliable design suitable for various industrial applications. Its unique ability to precisely manage flow rates sets it apart from other valve types and proves invaluable across different sectors. As industries continue to evolve and demand more efficient and effective fluid management solutions, the relevance and application of globe valves will undoubtedly expand. Understanding their functionality and versatility is key for engineers and technicians looking to optimize their systems for better performance and reliability. Whether in a water treatment plant or a chemical processing facility, the globe valve remains a cornerstone of fluid control technology.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS