Ное . 08, 2024 15:25 Back to list

standard pin gauge

Understanding Standard Pin Gauges

In the realm of precision engineering and manufacturing, the importance of accurate measurements cannot be overstated. One of the tools that play a critical role in measuring dimensions and ensuring quality control is the pin gauge. Specifically, standard pin gauges are essential for various applications across multiple industries, from automotive to aerospace, and even in the medical field. This article delves into the significance, types, applications, and benefits of using standard pin gauges.

What is a Standard Pin Gauge?

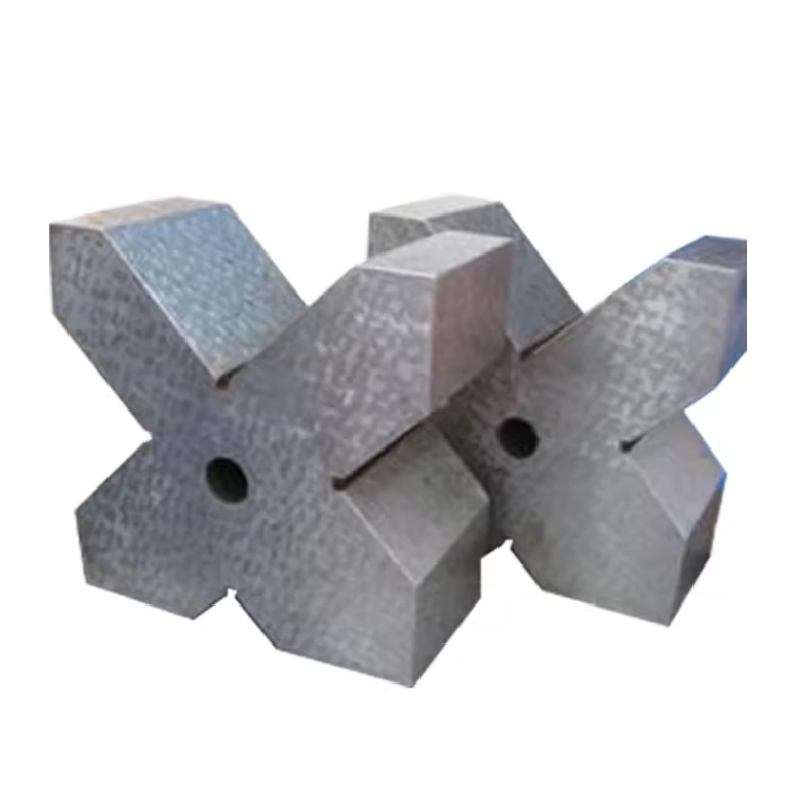

A standard pin gauge is a cylindrical tool made to precise dimensions used for checking the diameter of holes and ensuring that parts fit properly. These gauges are produced with high accuracy and often calibrated to conform to national and international measurement standards, ensuring consistency and reliability in measurements. Pin gauges are usually made from materials like steel, carbide, or stainless steel, depending on the application’s requirements.

Types of Pin Gauges

Pin gauges can be categorized into two main types fixed pin gauges and sets of pin gauges.

1. Fixed Pin Gauges These are individual pins that come in predetermined sizes. They are generally used for checking specific dimensions, such as hole sizes or distances between specific points on a workpiece. Fixed pin gauges provide a quick and clear way to determine whether a component meets the necessary specifications.

2. Sets of Pin Gauges This includes a complete set of pins in various sizes. These sets enable users to perform a range of measurements without needing to purchase multiple individual gauges. Sets can be used to check the tolerance of a hole and determine whether it falls within the acceptable range by using multiple pins to find a match.

Applications of Standard Pin Gauges

Standard pin gauges are versatile tools employed in several applications

. Some common use cases include- Quality Control In manufacturing, they are used to ensure that parts meet drawing specifications. If a pin fits correctly into a hole, it indicates that the part is within the specified tolerance levels.

standard pin gauge

- Machining During the machining process, pin gauges can help verify that machined features are correctly sized before proceeding to the next production step.

- Assembly Processes They can be used to check the fit of components before assembly, ensuring that all parts will function as intended without unnecessary friction or looseness.

- Tooling and Jigs Pin gauges are often used in the designing of tooling and jigs. By ensuring that the dimensions are accurate, engineers can design their tooling around these specifications.

Benefits of Using Standard Pin Gauges

The adoption of standard pin gauges comes with numerous advantages

- Accuracy Standard pin gauges are manufactured to stringent tolerances, providing reliable measurements that can significantly enhance product quality.

- Ease of Use These tools can be quickly handled and provide immediate feedback on whether a part meets dimension specifications, making them user-friendly.

- Cost-Effectiveness By using pin gauges for quality control, manufacturers can reduce the costs associated with defective products and rework.

- Versatility The range of sizes available makes standard pin gauges suitable for various industries and applications.

Conclusion

In summary, standard pin gauges are indispensable tools in the manufacturing and engineering sectors. Their ability to deliver precise measurements in a user-friendly manner makes them essential for quality control, machining, assembly, and tooling. As industries continue to prioritize precision and accuracy, the role of standard pin gauges will undoubtedly remain crucial in ensuring that products meet the highest standards of quality and function. Understanding and utilizing pin gauges can lead to enhanced operational efficiency and better overall product outcomes.

-

Surface Plate Maintenance Best Practices for LongevityNewsJun.27,2025

-

Historical Evolution of Iron Surface Plates in Industrial MetrologyNewsJun.27,2025

-

Cast Iron Y Strainer Safety StandardsNewsJun.27,2025

-

Blockchain Verification for Gauge Tool Certification IntegrityNewsJun.27,2025

-

Advantages of Triple Offset Butterfly Valve Types in High-Pressure SystemsNewsJun.27,2025

-

Wear Resistance Strategies for Trapezoidal ThreadsNewsJun.26,2025

Related PRODUCTS