Фев . 15, 2025 08:26 Back to list

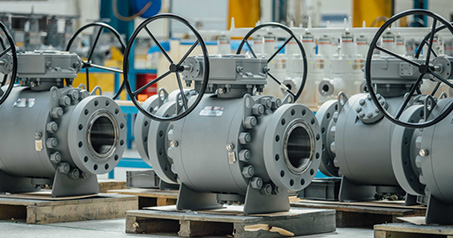

Ball Check Valve

A one-way ball check valve, often considered a staple in fluid control systems, serves as an essential component in various industrial applications. Its primary function is to allow fluid to flow in one direction while preventing backflow, thereby ensuring system efficiency and safeguarding against potential damage. With increasing demand for precise fluid control, understanding the intricacies of these valves is paramount for industry professionals seeking to enhance their operational systems.

Exploring the environmental impact, one-way ball check valves contribute to more sustainable operations by promoting efficient resource use. In scenarios involving the transportation of fluids over long distances, these valves help maintain pressure, reducing energy consumption and minimizing the carbon footprint. Innovations in sensor technology have further advanced the capabilities of these valves. Modern systems can now incorporate sensors to provide real-time data on valve performance, identifying potential issues before they escalate. This predictive maintenance approach not only enhances reliability but also optimizes resource allocation, potentially reducing costs. The evolution of materials science continues to push the boundaries of what one-way ball check valves can achieve. Research into new alloys and composite materials promises valves that are not only more durable but also lighter and more cost-effective, opening the door to new applications and broader market adoption. For industry insiders, leveraging such technological advancements and understanding the intricacies of one-way ball check valves is not merely beneficial—it's essential. Companies investing in training and research to enhance their personnel's expertise are better positioned to capitalize on these developments, translating to improved efficiency and market competitiveness. In summary, the one-way ball check valve remains an indispensable component in fluid systems across numerous industries. Its straightforward yet effective design, combined with the continuous advancements in material science and technology, ensures that it will continue to play a pivotal role in fluid control applications. By focusing on its maintenance, proper installation, and integration with modern technology, businesses can trust in the reliability and efficiency that these valves offer.

Exploring the environmental impact, one-way ball check valves contribute to more sustainable operations by promoting efficient resource use. In scenarios involving the transportation of fluids over long distances, these valves help maintain pressure, reducing energy consumption and minimizing the carbon footprint. Innovations in sensor technology have further advanced the capabilities of these valves. Modern systems can now incorporate sensors to provide real-time data on valve performance, identifying potential issues before they escalate. This predictive maintenance approach not only enhances reliability but also optimizes resource allocation, potentially reducing costs. The evolution of materials science continues to push the boundaries of what one-way ball check valves can achieve. Research into new alloys and composite materials promises valves that are not only more durable but also lighter and more cost-effective, opening the door to new applications and broader market adoption. For industry insiders, leveraging such technological advancements and understanding the intricacies of one-way ball check valves is not merely beneficial—it's essential. Companies investing in training and research to enhance their personnel's expertise are better positioned to capitalize on these developments, translating to improved efficiency and market competitiveness. In summary, the one-way ball check valve remains an indispensable component in fluid systems across numerous industries. Its straightforward yet effective design, combined with the continuous advancements in material science and technology, ensures that it will continue to play a pivotal role in fluid control applications. By focusing on its maintenance, proper installation, and integration with modern technology, businesses can trust in the reliability and efficiency that these valves offer.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS