Јун . 25, 2025 09:16 Назад на списокот

Educational Importance of Pin Gauges in Mechanical Engineering Labs

In the realm of mechanical engineering education, precision measurement tools are indispensable for fostering technical expertise and ensuring students grasp fundamental principles of dimensional accuracy. Among these tools, pin gauges stand out as critical instruments for hands-on learning. These simple yet highly specialized devices play a pivotal role in labs, enabling students to validate tolerances, inspect machined components, and understand industrial quality control processes. This article explores the educational significance of pin gauges, focusing on four key variants: metric gauge pins, standard pin gauge, thread pin gauge, and general pin gauge applications. By integrating these tools into curricula, institutions empower future engineers with practical skills aligned with industry standards.

The Role of Metric Gauge Pins in Precision Measurement

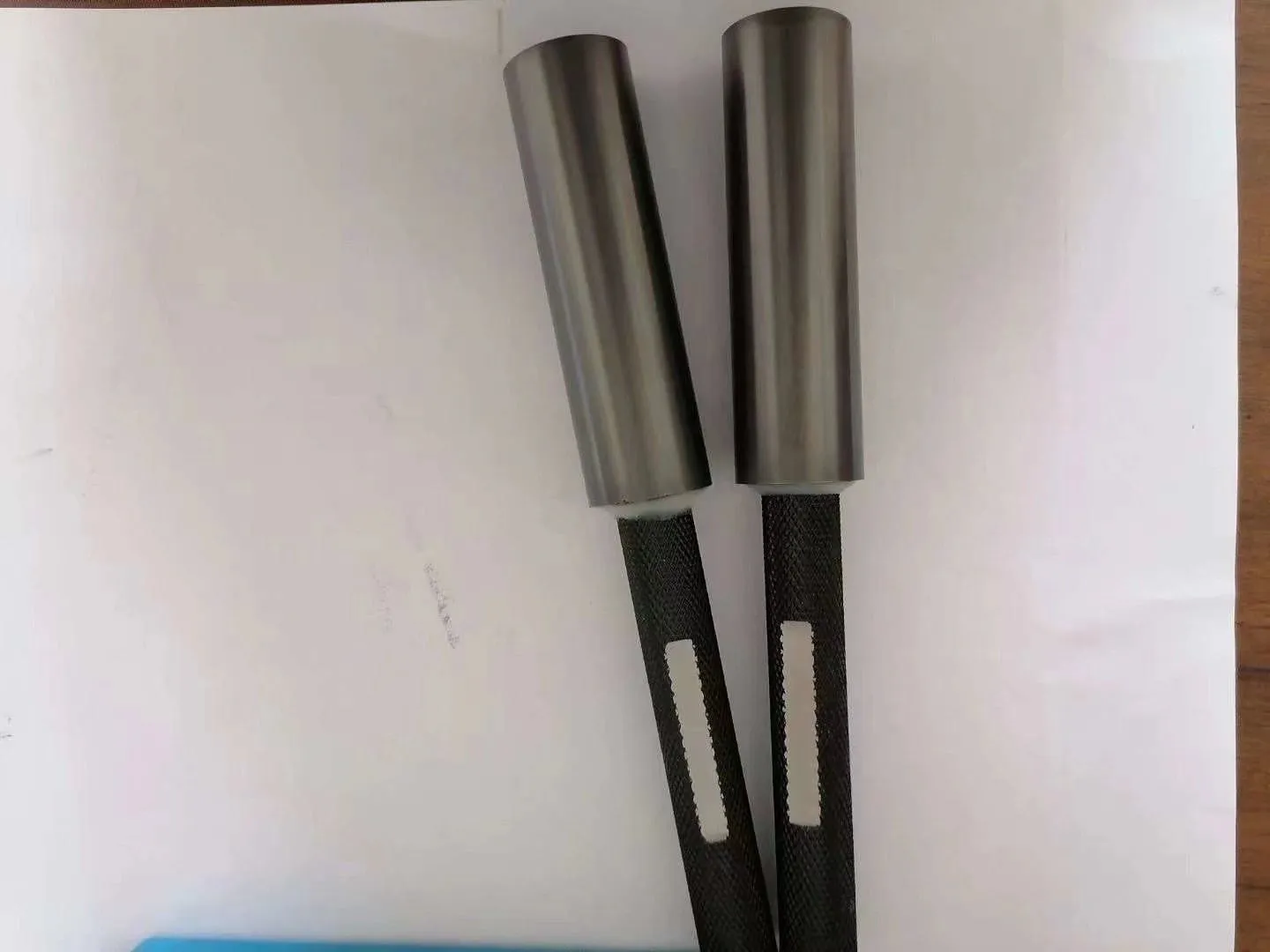

Metric gauge pins are foundational tools in mechanical engineering labs, particularly in regions or industries where the metric system prevails. These cylindrical pins, manufactured to precise metric dimensions, allow students to measure bore diameters, slot widths, and other internal features with micron-level accuracy. In educational settings, metric gauge pins teach learners the importance of unit consistency and international standardization.

For instance, during a lab exercise, students might use a set of metric gauge pins to verify the internal diameter of a machined hole. By selecting pins of incremental sizes and testing their fit, they learn to interpret tolerance zones (e.g., H7/g6) and assess whether a component meets design specifications. This process reinforces theoretical concepts like maximum material condition (MMC) and geometric dimensioning and tolerancing (GD&T).

Moreover, metric gauge pins introduce students to calibration practices. Since these tools are subject to wear over time, learners gain firsthand experience in maintaining measurement integrity—a skill directly transferable to quality assurance roles in manufacturing. By emphasizing traceability to international standards (e.g., ISO), labs equipped with metric gauge pins prepare students for global engineering challenges.

Standard Pin Gauge as a Foundation for Dimensional Accuracy

The standard pin gauge serves as a universal reference for dimensional verification across mechanical systems. Unlike specialized variants, these gauges adhere to widely recognized inch-based or metric dimensions, making them versatile for diverse lab applications. In educational contexts, standard pin gauges are often the first introduction students have to physical measurement tools, bridging the gap between digital simulations and real-world inspection.

A key lesson involving standard pin gauges is the concept of "go/no-go" testing. Students use a two-pin set—a "go" gauge (maximum acceptable size) and a "no-go" gauge (minimum acceptable size)—to quickly determine if a machined part falls within tolerance. This method mimics industrial quality control workflows, teaching efficiency and critical thinking. For example, if a standard pin gauge "go" pin fits into a hole but the "no-go" pin does not, the part passes inspection.

Additionally, standard pin gauges emphasize the importance of material selection. Engineering labs often showcase gauges made from tool steel or carbide, demonstrating how material properties like hardness and thermal stability affect longevity. Students learn to match tool characteristics to application requirements—a decision-making process vital for future design engineers.

Thread Pin Gauge for Specialized Applications in Engineering Labs

Thread pin gauges add a layer of specialization to mechanical engineering education by focusing on threaded components. These gauges feature precisely machined threads to assess the pitch, major diameter, and functional integrity of nuts, bolts, and tapped holes. In labs, thread pin gauges teach students to evaluate one of the most complex yet ubiquitous mechanical features: the screw thread.

A common exercise involves using a thread pin gauge to inspect a threaded hole. Students first engage the gauge by hand, ensuring smooth rotation without binding—a sign of correct pitch alignment. This tactile feedback reinforces the relationship between thread geometry (e.g., UNC, UNF) and functional performance. Advanced labs might combine thread pin gauges with optical comparators to analyze thread profiles microscopically, merging traditional metrology with modern analytical techniques.

Furthermore, thread pin gauges highlight the consequences of thread wear or improper machining. A worn or incorrectly tapped thread can lead to assembly failures or mechanical loosening, topics often explored in failure analysis modules. By identifying defects early using thread pin gauges, students cultivate a proactive approach to design and manufacturing.

Comprehensive Applications of Pin Gauge in Modern Mechanical Training

Beyond specific subtypes, the general pin gauge exemplifies adaptability in engineering education. From basic dimensional checks to advanced research projects, these tools support a wide range of learning objectives. For example, in a reverse engineering lab, students might use pin gauges to reverse-dimension a legacy component lacking CAD documentation. This exercise sharpens problem-solving skills and underscores the value of empirical measurement.

In additive manufacturing (3D printing) labs, pin gauges validate the accuracy of printed parts, exposing students to the limitations and opportunities of emerging technologies. A printed hole that appears dimensionally correct on-screen might deviate by fractions of a millimeter post-printing—a discrepancy easily caught with a pin gauge. Such experiences teach learners to balance digital design with physical reality.

Collaborative projects further amplify the educational impact of pin gauges. In capstone courses, student teams might design a multi-component assembly, using pin gauges to ensure interoperability. This mirrors real-world product development, where interdisciplinary teams rely on standardized measurement tools to maintain coherence across subsystems.

FAQs About Pin Gauge Products

How do metric gauge pins differ from inch-based pin gauges?

Metric gauge pins are calibrated in millimeters, aligning with ISO standards, whereas inch-based gauges use fractional or decimal inch units. The choice depends on regional or project-specific measurement systems.

Can a standard pin gauge be used for both internal and external measurements?

While standard pin gauges are primarily designed for internal measurements (e.g., holes), they can indirectly assess external features by serving as references in comparator setups.

What maintenance is required for thread pin gauges?

Thread pin gauges should be cleaned after each use to prevent debris buildup. Periodic calibration checks ensure thread profiles remain within specified tolerances.

Are pin gauges suitable for high-volume production environments?

Yes, pin gauges are widely used in high-volume manufacturing for rapid inspection. Their durability and repeatability make them ideal for quality control stations.

How do I select the right pin gauge set for an educational lab?

Consider the lab’s focus (e.g., general machining, aerospace) and measurement system (metric/inch). A combination set covering multiple tolerance grades offers flexibility for diverse projects.

The integration of pin gauges—metric gauge pins, standard pin gauge, thread pin gauge, and general-purpose variants—into mechanical engineering curricula equips students with practical metrology skills. These tools transform abstract theories into tangible experiences, fostering attention to detail, adherence to standards, and an analytical mindset. As manufacturing evolves, the foundational knowledge gained through pin gauges ensures graduates are prepared to innovate while upholding the precision that defines mechanical engineering excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlВестиAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseВестиAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsВестиAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesВестиAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingВестиAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlВестиAug.05,2025

Поврзани производи