Ное . 24, 2024 09:03 Back to list

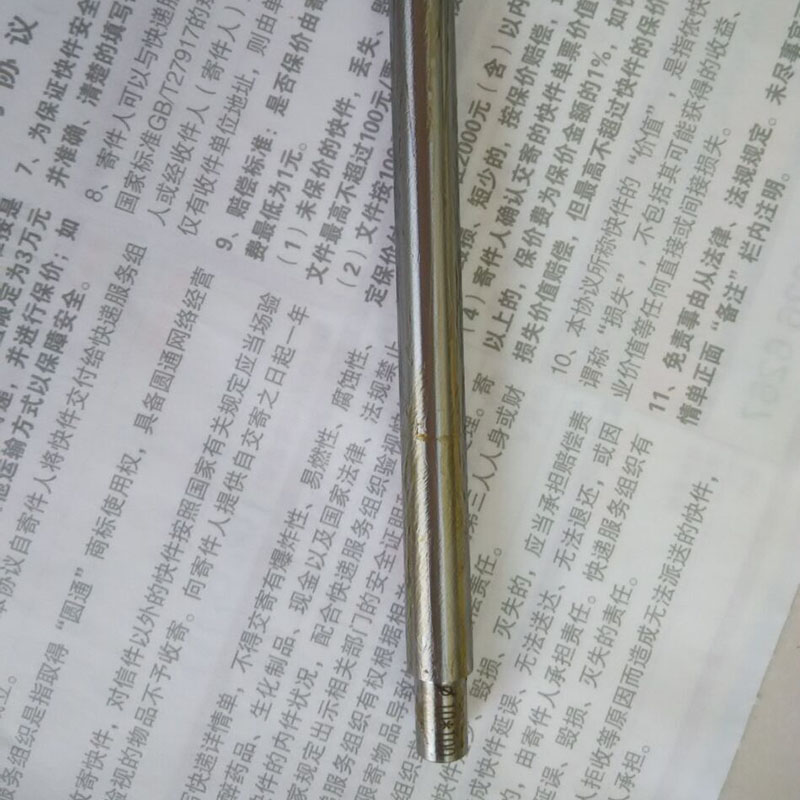

3 8 gate valve

Understanding the 3 8% Gate Valve A Comprehensive Overview

In the world of plumbing and piping systems, valves play an imperative role in controlling the flow of fluids. Among the various types of valves, the gate valve stands out due to its straightforward design and reliability. The 3 8% gate valve is a specific type that showcases both mechanical simplicity and effective performance. This article delves into the features, advantages, and applications of the 3 8% gate valve, providing a comprehensive understanding of its utility in various sectors.

What is a Gate Valve?

A gate valve is a type of linear valve that opens by lifting a gate (or wedge) out of the path of the fluid, allowing for full flow in either direction. Unlike other valves that might throttle the flow, gate valves are primarily used for on/off control. They offer minimal flow resistance when fully open, making them highly efficient for applications where the complete flow is essential.

Design Features of the 3 8% Gate Valve

The designation 3 8% is often used to specify certain dimensions and characteristics of this particular gate valve. The percentages, in this context, could signify variations in size or design standards that meet specific industrial requirements. For instance, the valve might be designed to withstand high pressure or corrosive substances, making it suitable for environments like oil and gas pipelines, water treatment facilities, and industrial manufacturing.

Typically, the 3 8% gate valve consists of robust materials such as stainless steel, bronze, or cast iron, providing excellent durability and resistance to wear and tear. Its sealing components are essential to prevent leakage, and commonly, these are made from high-quality elastomers capable of withstanding extreme conditions.

Advantages of the 3 8% Gate Valve

1. Full Flow Capability The design of a gate valve allows for full flow when opened, which is vital in preventing pressure drops and maximizing efficiency in fluid transport systems.

3 8 gate valve

2. Low Pressure Drop Unlike globe valves or ball valves, gate valves produce minimal pressure drops, making them ideal for applications where fluid flow is critical.

3. Versatility The 3 8% gate valve can be employed in a multitude of industries, including but not limited to municipal water systems, petrochemical plants, and HVAC applications. This versatility makes it a go-to solution for engineers and project managers.

4. Durability The robust construction materials ensure a long life span and reliability under various environmental conditions, minimizing the need for frequent replacements and maintenance.

5. Ease of Operation Gate valves can be easily operated manually with a handwheel, or they can be automated with electric or pneumatic actuators, providing greater flexibility depending on the need of the operation.

Applications

The 3 8% gate valve finds its application in various sectors. In the water and wastewater industry, it is often utilized for controlling water flow and ensuring safety in treatment processes. In oil and gas pipelines, its capacity to handle high pressure while maintaining full flow makes it indispensable. Furthermore, in industrial plants, gate valves serve critical roles in managing steam, chemicals, and other fluids essential for manufacturing processes.

Conclusion

In conclusion, the 3 8% gate valve is a reliable and efficient component in the fluid control landscape. With its unique features and numerous advantages, it is well-suited for a wide range of applications across various industries. Understanding its capabilities allows engineers and technicians to make informed decisions, ensuring optimal performance and longevity of their fluid transport systems. As industries continue to evolve, the role of such reliable components will undoubtedly remain pivotal in achieving operational excellence.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS