Jul . 03, 2025 09:15 Hoki ki te rarangi

How to Carve a Block of Granite

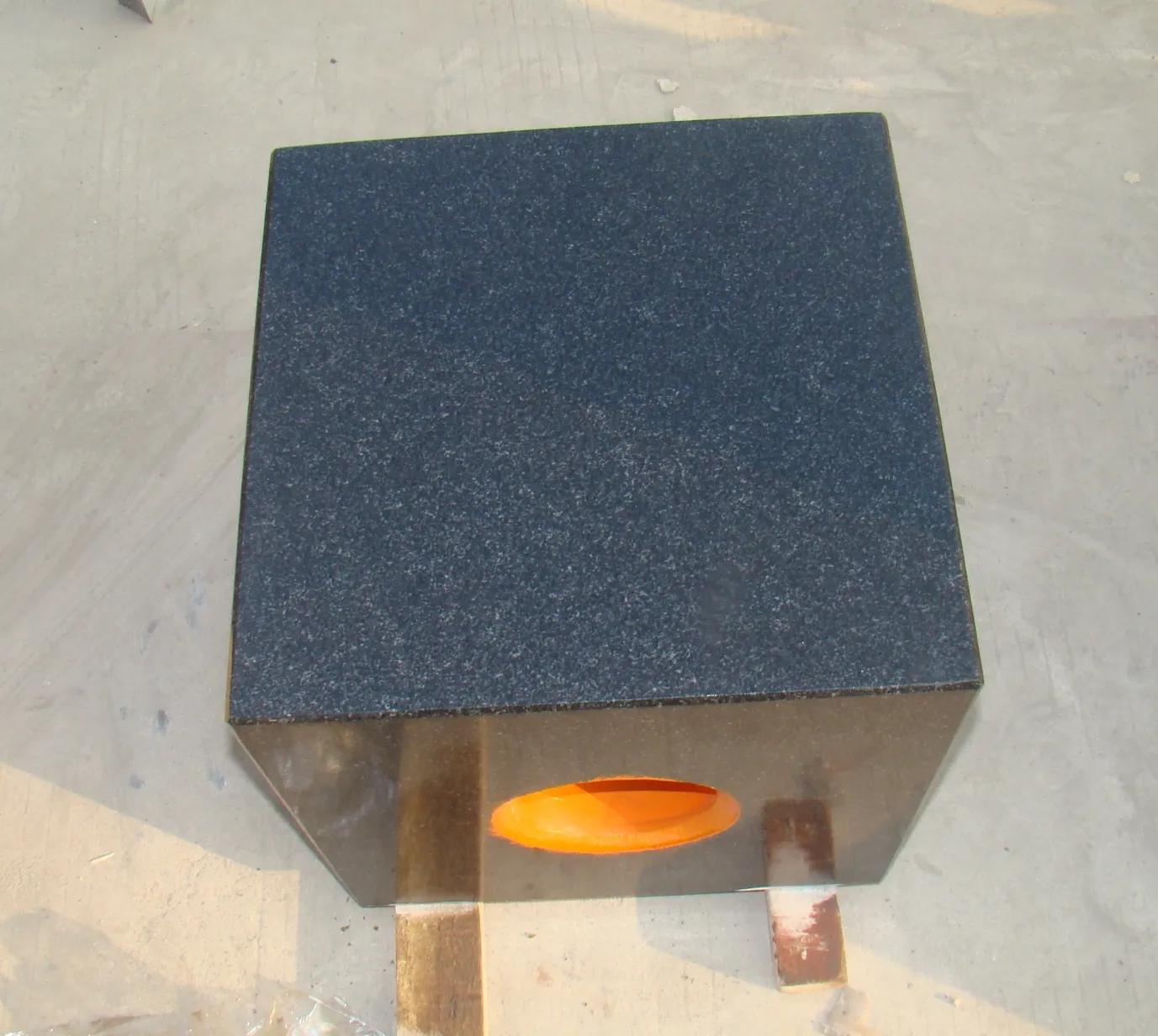

In the stone - working industry, mastering the art of carving a block of granite is essential for wholesalers aiming to provide high - quality products like granite boxes. Storaen (Cangzhou) International Trading Co. recognizes the significance of this skill in delivering top - tier granite products.

Understanding the Block of Granite

- A block of granite is a sturdy and dense natural stone, characterized by its hardness on the Mohs scale, usually ranging from 6 - 7. This hardness makes it suitable for creating durable products such as granite boxes that can withstand heavy use and harsh environments.

- The mineral composition and grain structure of a block of granitevary, influencing the carving process. Blocks with a uniform grain are easier to work with, allowing for more consistent cuts when shaping a granite box. Identifying flaws like cracks or uneven density in the block before carving is crucial to avoid issues during the process and ensure the quality of the final product.

- Granite's resistance to weathering, abrasion, and chemical corrosion ensures the longevity of granite boxes. This makes it an ideal choice for wholesalers to promote to clients who require long - lasting, reliable stone products for industrial, architectural, or decorative purposes.

Tools Required for Carving a Block of Granite

- Cutting Tools: Diamond - tipped saws are indispensable for cutting a block of granite. Their hardness enables them to slice through the tough stone, creating the rough shape for granite boxesor other carved items. These saws come in various sizes and types, depending on the scale of the project.

- Shaping Tools: Diamond - coated burrs and rotary tools are used for detailed shaping. They can carve intricate designs, smooth edges, and create the precise dimensions required for a granite box, ensuring a professional finish.

- Traditional Tools: Chisels and hammers can be used to break off larger chunks of the block of graniteat the initial stages. However, they must be used with caution to prevent micro - cracks that could compromise the integrity of the final product.

- Finishing Tools: Polishing pads of different grits, from coarse to fine, are essential for achieving a smooth and glossy finish on the carved block of granite. This not only enhances the aesthetic appeal of granite boxesbut also provides a protective layer, increasing their durability.

Step - by - Step Carving Process for Granite Boxes

- Design Conception: Begin by sketching the design of the granite boxon paper or using computer - aided design (CAD) software. Consider the size and shape of the block of granite available, as well as the intended use of the box. Factors like grain direction should also be factored in to optimize the strength and appearance of the final product.

- Rough Cutting: Use a diamond - tipped saw to cut the block of graniteinto the basic shape of the granite box. This involves separating the base, sides, and lid if applicable. Precise measurements and cuts at this stage are important to minimize material waste and ensure a proper fit for the components.

- Rough Shaping: Employ diamond burrs to remove excess material and shape the block further. For a granite box, carve out the interior cavity and refine the outer surfaces, ensuring uniform wall thickness and smooth contours. Work slowly and carefully to avoid over - carving and damaging the block.

- Detailed Carving: Switch to finer burrs for detailed work. This includes adding engravings, patterns, or any other decorative elements to the granite box. Pay close attention to joints and connections to ensure a snug fit between the different parts of the box.

- Polishing: Start with coarse - grit polishing pads to smooth out tool marks and rough surfaces. Gradually progress to finer grits to achieve a high - gloss finish. Polishing not only improves the look of the granite boxbut also helps to seal the stone, protecting it from stains and damage.

Comparing Granite Box and Marble Box Carving

- Material Properties: Granite boxcarving requires more robust tools due to granite's hardness. In contrast, marble box carving can be done with relatively softer tools as marble has a lower Mohs hardness. Granite has a more uniform grain, while marble features distinct veining, which affects the design and carving approach.

- Carving Techniques: When carving a block of graniteinto a granite box, more force and precision are needed. The process is often slower to avoid chipping or cracking. Marble box carving allows for more fluid and detailed work in some aspects, but marble is more prone to scratching and chipping, requiring careful handling.

- Product Applications: Granite boxesare ideal for heavy - use applications, such as in industrial settings or for storing tools, due to their durability. Marble boxes, on the other hand, are often chosen for decorative purposes in homes or showrooms because of their elegant appearance and unique veining patterns.

Block of Granite Carving FAQS

Can any block of granite be used to carve a granite box?

Not all block of granites are suitable. The block should be free from major flaws like large cracks or excessive impurities. Additionally, its size and shape should be appropriate for the design of the granite box. Storaen (Cangzhou) International Trading Co. carefully selects high - quality blocks to ensure successful carving projects.

How long does it take to carve a granite box from a block of granite?

The time depends on the complexity of the design, the size of the granite box, and the carver's skill level. Simple designs may take a few days, while more intricate ones can take weeks. The hardness of the block of granite also affects the carving speed, as harder stones require more time and effort.

Is it more expensive to carve a granite box compared to a marble box?

Generally, granite box carving can be more expensive due to the need for specialized, durable tools and the longer carving time required. However, the cost also depends on the quality and availability of the raw materials. Marble boxes may have their own cost factors, such as the price of high - quality marble and the need for extra care during carving to prevent damage.

Can a damaged granite box carved from a block of granite be repaired?

Minor damages like surface scratches can often be repaired through re - polishing. For more significant damage, such as cracks, professional stone repair techniques can be used. In some cases, parts of the granite box may need to be replaced. Storaen (Cangzhou) International Trading Co. can provide guidance on repair options for clients.

What are the key selling points of granite boxes for wholesalers?

Granite boxes offer exceptional durability, resistance to wear and tear, and a long lifespan. Their aesthetic appeal, especially in colors like black, makes them attractive for various applications. Additionally, the fact that they are carved from a natural, sustainable material like a block of granite can be a selling point for environmentally conscious clients.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsRongorongoAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlRongorongoAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsRongorongoAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsRongorongoAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsRongorongoAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsRongorongoAug.20,2025

HUA e pa ana