Oct . 09, 2024 04:51 Back to list

Understanding Thread Gauge Sizes and Their Applications in Various Industries

Understanding Thread Gauge Sizes An Essential Guide

When it comes to mechanical engineering, construction, and manufacturing, thread gauge sizes play a critical role in ensuring that components fit together securely and efficiently. Thread gauges are tools used to measure the pitch and diameter of threaded fasteners, and they come in various sizes to accommodate the vast range of threads commonly used in different applications. Understanding these measurements is essential for anyone working in these fields, as it affects not only the integrity of the assembly but also the overall performance of the machinery or product being developed.

What Are Thread Gauges?

Thread gauges are precision instruments designed to check the size and shape of threads in bolts, nuts, and other fasteners. They come in several types, including pitch gauges and screw pitch gauges. Pitch gauges measure the distance between threads, which is known as the pitch. This measurement is crucial because threads that do not match in size and pitch can result in weak connections, stripped threads, or even catastrophic failures in critical systems.

Common Thread Gauge Sizes

Threads are usually classified by their diameter and the number of threads per inch (TPI) for imperial measurements, or by their diameter and the thread pitch in millimeters for metric measurements. Understanding the common gauge sizes leads to better decision-making when selecting the right fasteners for a job.

thread gauge sizes

For example, in the Imperial system, common sizes include 1/4, 5/16, and 3/8 with corresponding TPI values such as 20, 18, and 16, respectively. In the metric system, sizes may range from M2 (2 mm diameter) to M30 (30 mm diameter) with pitch values such as 0.4, 0.5, or 1.0 mm.

Additionally, thread gauges may come in different classes of fit, such as class 1A and 1B, which indicate the precision of the fit between the male and female threads. These classifications help engineers select the right fit for specific applications, balancing the ease of assembly with the desired level of tightness.

Applications of Thread Gauges

Thread gauges are not only essential for measuring existing threads but are also crucial during the design and prototyping stages in manufacturing. Engineers utilize thread gauges to verify that their designs adhere to standardized measurements, thereby reducing the likelihood of errors during production. Whether it’s automotive, aerospace, or consumer product manufacturing, thread gauge sizes are vital for ensuring that components are interchangeable and meet safety regulations.

Conclusion

In summary, thread gauge sizes are fundamental to many industries, providing the necessary accuracy and consistency for threaded fasteners. Understanding how to measure and apply various thread sizes ensures that engineers and technicians can produce reliable and safe products. Whether you are involved in manufacturing, construction, or maintenance, familiarity with thread gauges will undoubtedly enhance your ability to work effectively with threaded connections, ultimately contributing to higher standards of quality and safety in engineering practices. As technology advances and new materials and designs emerge, maintaining a solid understanding of these fundamental tools will remain indispensable in the professional toolkit.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

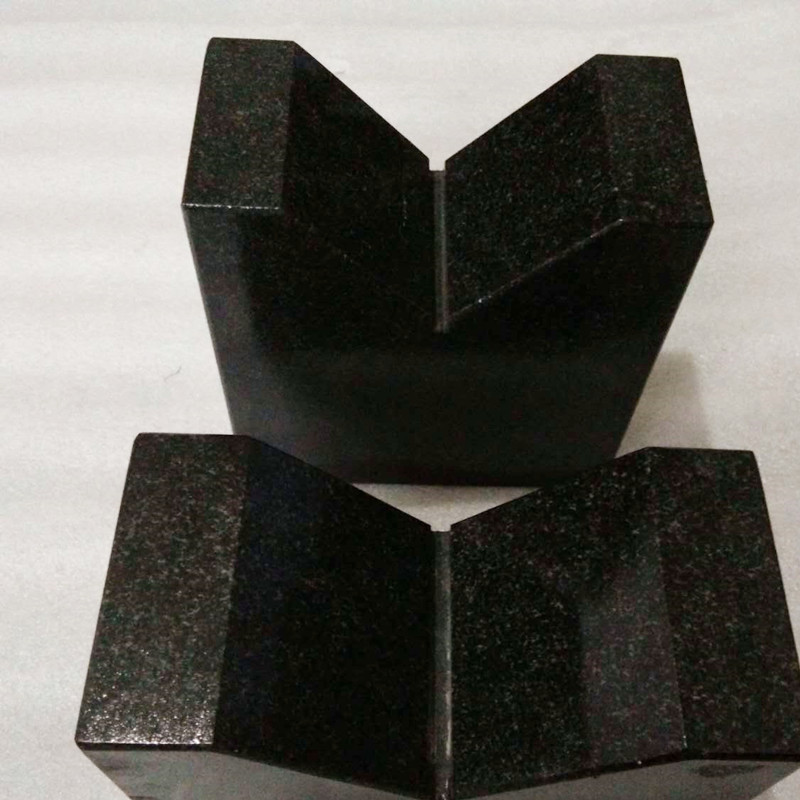

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS