Nov . 26, 2024 10:21 Hiverina any amin'ny lisitra

Precision and Durability with Granite Measuring Tools

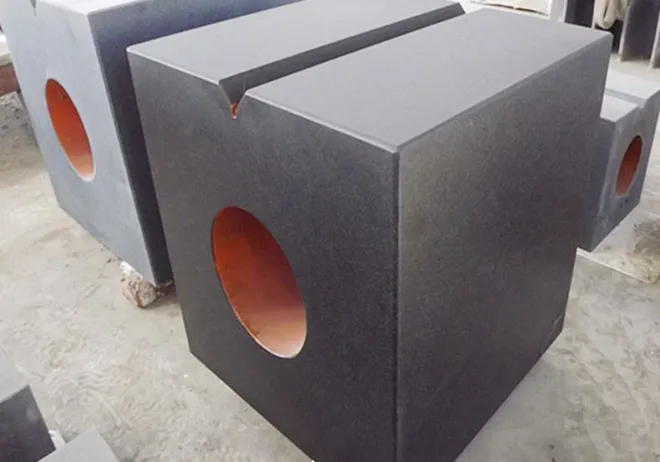

When it comes to accurate measurements and long-lasting quality, granite measuring tools are the preferred choice for professionals across many industries. From granite surface plates to specialized measuring tools, the reliability of these tools is unmatched. Discover the benefits of granite industrial tools and where to find high-quality granite tools for sale to support your precision needs.

Why Choose Granite Measuring Tools?

A granite measuring tool provides unparalleled stability and accuracy due to granite’s natural properties. Granite is highly resistant to wear and does not warp over time, making it ideal for use in measuring surfaces and equipment calibration. Granite surface plates, for example, maintain their flatness and precision even in demanding environments. These tools are essential in machining, manufacturing, and quality control, where even minor inaccuracies can lead to costly errors.

Benefits of Granite in Industrial Applications

Granite industrial tools are known for their ability to withstand heavy use while maintaining accuracy. Industrial applications, particularly in manufacturing and metalworking, demand tools that can handle frequent use without degradation. Granite’s non-magnetic, corrosion-resistant properties make it perfect for supporting various processes. The sturdiness of granite ensures that these tools can handle large, heavy parts without affecting measurement precision. Additionally, granite tools are naturally stable and less affected by temperature fluctuations, which is critical in maintaining accuracy.

Finding High-Quality Granite Tools for Sale

Looking for reliable granite tools for sale? Finding the right supplier is crucial to ensure that the tools meet industry standards for quality and durability. Whether you need surface plates, straight edges, or specialized granite gauges, reputable suppliers offer tools that have undergone rigorous testing for flatness and accuracy. Investing in these high-quality granite tools guarantees a long service life, providing you with dependable performance for years. Trusted suppliers can also offer calibration and support services, which further enhance the value of your investment.

Choosing the Right Granite Measuring Tool for Your Needs

Selecting the right granite measuring tool depends on your specific measurement requirements. Surface plates are ideal for providing a reference plane, while granite straight edges and angles are used for precise alignment. When selecting a granite measuring tool, consider the required flatness grade and size to ensure that it meets your application’s precision needs. For high-precision tasks, granite tools with tighter tolerance levels are essential for achieving the desired results. Understanding your project’s demands will guide you to the right tools for maximum accuracy.

Maintenance Tips for Longevity of Granite Industrial Tools

Proper maintenance is key to keeping granite industrial tools in top condition. Regular cleaning with a soft cloth and avoiding exposure to harsh chemicals can preserve the granite surface. Periodic calibration and inspection will also ensure that the tools continue to provide accurate measurements. For those using these tools daily, taking care to avoid dropping or scratching the granite surface can greatly extend its life. Routine maintenance not only preserves the tool’s accuracy but also protects your investment, making it a wise practice for long-term value.

In conclusion, granite measuring tools and granite industrial tools offer unmatched durability and precision for professionals who demand the best. By choosing high-quality granite tools and following proper maintenance practices, you can ensure reliable performance and longevity. With a range of granite tools for sale from trusted suppliers, now is the perfect time to invest in tools that will elevate the precision and efficiency of your work.

-

Durable Cast Iron Y Strainer Solutions for Industrial BuyersNEWSJul.31,2025

-

Cast Iron Lapping Plates for Precision Engineering SolutionsNEWSJul.31,2025

-

Thread Plug Gauge Requires Careful HandlingNEWSJul.29,2025

-

Surface plate calibrationNEWSJul.29,2025

-

Ring Gauge Ensures Machining AccuracyNEWSJul.29,2025

-

Pad Iron Reinforces Anchor PointsNEWSJul.29,2025

PRODUCTS mifandraika