Nov . 15, 2024 22:22 Back to list

thread gauge plug

Understanding Thread Gauge Plugs An Essential Tool in Precision Engineering

In the world of precision engineering, maintaining tight tolerances and ensuring dimensional accuracy are critical aspects of manufacturing processes. One essential tool that plays a significant role in achieving these objectives is the thread gauge plug. This small yet vital device is designed to verify the accuracy of threaded holes, ensuring that they meet specific standards and specifications.

What is a Thread Gauge Plug?

A thread gauge plug is a specialized measuring instrument used to assess the dimensional characteristics of internal threads in various materials. These plugs are typically made of high-quality steel or other durable materials capable of withstanding the rigors of frequent use. They are precision-engineered to match specific thread profiles, including dimensions, pitch, and tolerances, as outlined in industry standards such as ANSI, ISO, and others.

Types of Thread Gauge Plugs

There are two primary types of thread gauge plugs the Go and No-Go gauges.

1. Go Gauge This component is designed to fit easily into a threaded hole that meets the required specifications. If the Go gauge can be inserted without any resistance, it indicates that the thread dimensions are within acceptable limits.

2. No-Go Gauge In contrast, the No-Go gauge is intended to verify whether a thread is oversized. It should not be able to enter the threaded hole when the threads are within tolerance. If the No-Go gauge fits, it signals that the internal threads are out of specification and may require reworking or replacement.

Importance of Using Thread Gauge Plugs

The precision of threaded connections is crucial in various industries, from automotive to aerospace to manufacturing. The following are several reasons why thread gauge plugs are an indispensable part of the quality assurance process

- Ensuring Compatibility Threaded components often need to fit together perfectly for optimal performance. Gauging internal threads ensures compatibility with external threads, minimizing the risk of mechanical failures.

thread gauge plug

- Maintaining Safety Standards In applications where safety is paramount, such as in aircraft and automotive components, precision-engineered threaded parts must adhere to strict safety standards. Regularly checking thread dimensions with gauge plugs helps ensure reliability and safety.

- Reducing Waste Identifying non-conforming threads early in the production process allows manufacturers to address issues before they escalate, reducing material waste and enhancing overall efficiency.

- Improving Productivity By minimizing the need for rework and ensuring that threaded parts meet specifications, using thread gauge plugs can streamline production processes and boost overall productivity.

How to Use Thread Gauge Plugs

Using thread gauge plugs is straightforward, but following correct procedures is critical for accurate results

1. Clean the Threaded Hole Before using the gauges, it’s essential to clean the threaded hole to remove any debris or contaminants that could affect the measurement.

2. Check with the Go Gauge Insert the Go gauge into the threaded hole. It should enter smoothly, indicating that the thread is within the acceptable dimension range.

3. Check with the No-Go Gauge Next, attempt to insert the No-Go gauge. If the No-Go gauge cannot be inserted, the thread is confirmed to be within tolerance. If it does fit, adjustments or rework will be necessary.

4. Document Results Maintaining a record of gauge measurements helps track quality trends and identify potential issues before they become significant problems.

Conclusion

Thread gauge plugs are essential tools in maintaining the integrity of threaded connections across various industries, ensuring safety, efficiency, and quality. By regularly utilizing these gauges, manufacturers can uphold stringent quality control standards, ultimately leading to higher-quality products and reduced costs. For anyone involved in precision engineering, understanding and effectively using thread gauge plugs is paramount to achieving long-term success in their manufacturing processes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

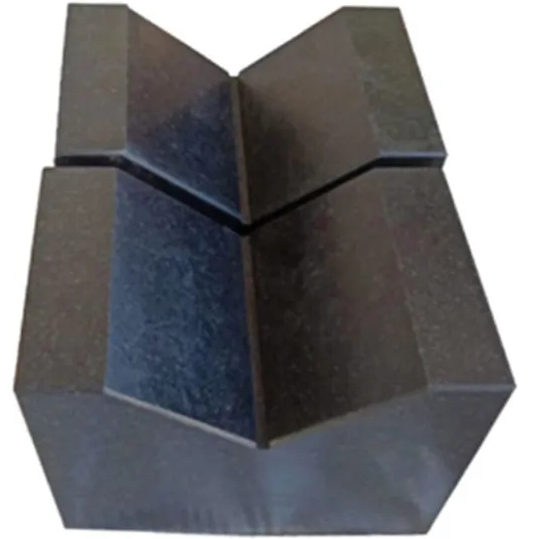

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS