Dec . 05, 2024 16:52 Back to list

3-Inch and 4-Inch Gate Valve Options for Efficient Flow Control in Plumbing Systems

Understanding the Basics of 3% and 4% Gate Valves

Gate valves play a crucial role in various industrial applications, particularly in controlling the flow of fluids in pipelines. Among the various specifications and types of gate valves, the 3% and 4% gate valves stand out due to their unique design features and operational advantages. This article aims to provide an in-depth understanding of these gate valves, detailing their functions, applications, and the advantages they offer.

What are Gate Valves?

Gate valves are linear motion valves that are used to start or stop the flow of fluid. Unlike globe valves, which are used for throttling purposes, gate valves are designed to be either fully open or fully closed, serving primarily as isolation devices. The mechanism behind a gate valve includes a wedge-shaped disc that moves up and down. When the valve handle is turned, the gate lifts away from the flow path, allowing fluid to pass through, and when the gate is lowered, it seals against the valve seat to stop the flow.

The Significance of 3% and 4% Specifications

The terms 3% and 4% associated with gate valves generally refer to the percentage of the valve opening size relative to the nominal diameter of the valve. These percentages indicate different degrees of restriction to the fluid flow, and understanding these can greatly enhance the efficiency of fluid systems.

1. 3% Gate Valves A gate valve designed to provide a 3% opening effectively limits the flow to a greater degree compared to a 4% valve. This tighter restriction is beneficial in applications where reducing flow is crucial, such as in certain chemical processing sectors or in systems requiring high precision in fluid distribution.

2. 4% Gate Valves Conversely, a 4% gate valve offers a slightly wider opening, allowing for increased flow rates. This variant is suitable for applications where a higher flow rate is required without significantly compromising on pressure. Industries including water treatment, HVAC, and oil and gas often utilize 4% gate valves for their versatility in accommodating different flow requirements.

Applications of 3% and 4% Gate Valves

Both 3% and 4% gate valves are widely used in various sectors. Some notable applications include

3 4 gate valve

- Water Supply Systems Gate valves are integral in municipal water systems, where they control the flow of treated water to consumers. - Oil & Gas In the oil and gas industry, gate valves are used for crude oil and natural gas operations, where they can effectively manage pressure fluctuations.

- Chemical Processing In chemical plants, the precise control offered by 3% gate valves helps in maintaining the required chemical reactions without any unnecessary fluid loss.

Advantages of 3% and 4% Gate Valves

1. Durability and Reliability Gate valves are known for their robust construction and reliability, which is crucial in environments where failure can lead to significant losses.

2. Low Pressure Drop When fully opened, gate valves provide a straight-through path for flow, minimizing pressure drop, which is essential for maintaining system efficiency.

3. Versatility With different percentage variations (3% vs. 4%), gate valves can be selected based on specific needs, allowing for customized solutions to fluid control challenges.

4. Maintenance Gate valves typically require less maintenance compared to other valve types, provided they are used correctly within their design limits.

Conclusion

In conclusion, the understanding and selection of the right type of gate valve, such as the 3% and 4% variants, are vital for ensuring effective fluid control in various applications. By considering the specific requirements of flow restriction and pressure management, industries can optimize their operations, enhance efficiency, and achieve better results in fluid management. Whether used in water treatment, oil and gas, or chemical processing, gate valves continue to be indispensable components of industrial infrastructure, ensuring safe and efficient fluid control.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

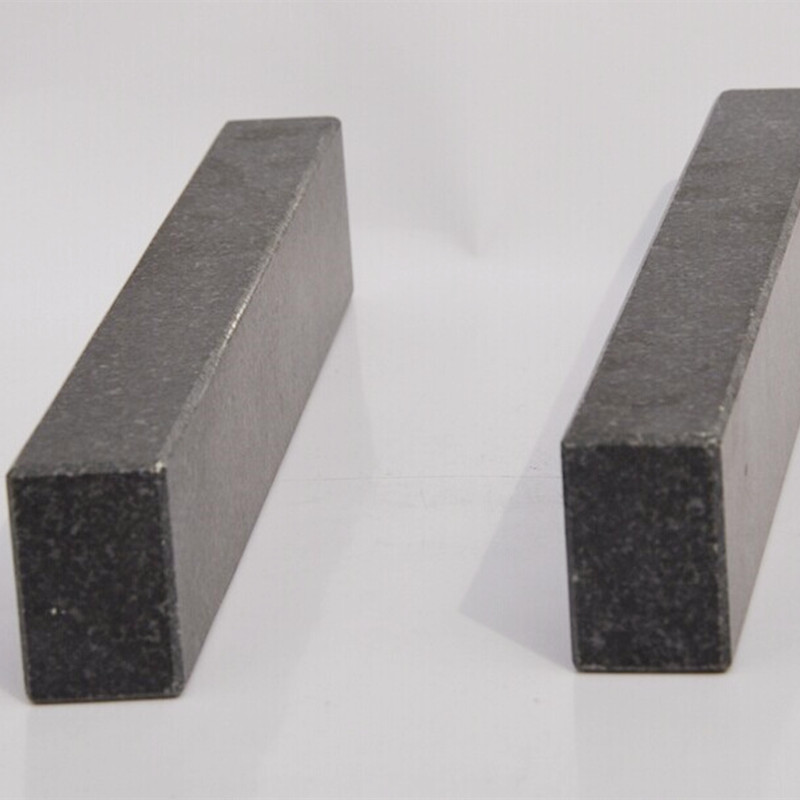

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS