Lap . 10, 2024 07:56 Back to list

Flange Types for Strainers and Their Applications in Industrial Systems

Understanding Strainer Flange Types An Essential Guide

Strainer flanges are critical components used in various industrial applications, primarily in piping systems that involve the transport of liquids and gases. These devices serve the primary function of filtering out debris and particles from the flow, ensuring that the system operates effectively and efficiently. This article delves into the different types of strainer flanges, their applications, advantages, and considerations when selecting the appropriate type for a specific application.

What is a Strainer Flange?

A strainer flange is a specialized type of strainer that integrates with pipe flanges to provide a secure filtration solution. It is designed to catch particulates, sediments, and other unwanted materials from the flow, which can be critical for maintaining the longevity of machinery downstream. Typically constructed from materials such as stainless steel, carbon steel, or fiberglass, these strainers can withstand various environmental conditions and corrosive substances.

Types of Strainer Flanges

Strainer flanges can be categorized based on several features, including design, connection type, and filtration capability

1. Y-Strainers Shaped like a Y, these strainers are ideal for horizontal and vertical pipeline installation. Y-strainers are often used in applications where maintenance is manageable since they allow for easy cleaning and replacement.

2. Basket Strainers These are designed with a basket that captures larger particles while allowing the fluid to flow through. Basket strainers can be used in applications where greater flow rates are required, and they are often fitted with a removable basket that makes maintenance straightforward.

3. T-Strainers Symmetrical in design, T-strainers are versatile and can be utilized in both horizontal and vertical orientations. They typically come with a removable screen that allows for easy cleaning and inspection.

4. Cone Strainers This type features a conical design which provides a larger surface area for filtration, suitable for applications that involve high flows and significant particulate matter.

Applications of Strainer Flanges

Strainer flanges are extensively used in various industries, including

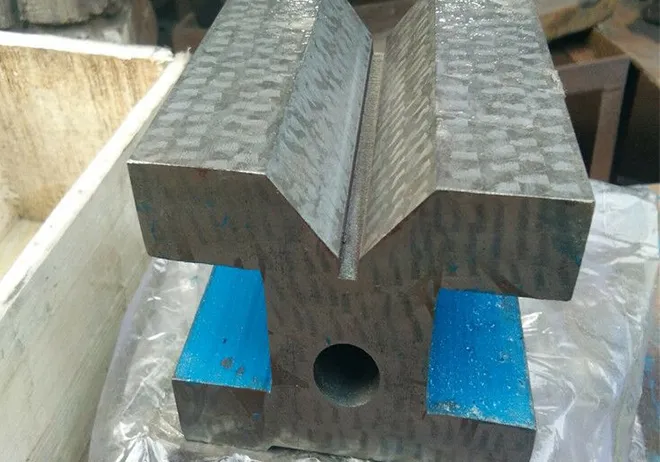

strainer flange type

- Oil and Gas To filter out sediment and debris from crude oil and natural gas. - Water Treatment Protecting equipment from rust, sediment, and scale in water treatment plants. - Chemical Processing Ensuring that chemicals are free of contaminants that could affect product quality. - HVAC Systems Preventing particles from damaging pumps and valves.

Advantages of Using Strainer Flanges

1. Protection of Equipment By filtering out harmful particles, strainer flanges protect critical components like pumps, valves, and heat exchangers, thus reducing the need for repairs and downtime.

2. Improved System Efficiency Clean fluid flow reduces energy consumption, enhancing the efficiency of pumps and other equipment.

3. Cost-Effectiveness The initial investment in strainer flanges can lead to significant savings by extending the lifespan of equipment and minimizing maintenance costs.

4. Versatility With various designs available, strainer flanges can be adapted to suit a wide range of applications and piping configurations.

Considerations When Selecting a Strainer Flange

When choosing a strainer flange, several factors must be considered

- Flow Rate Ensure the selected strainer can handle the necessary flow without causing pressure drops. - Filtration Needs Determine the particle size you need to filter and choose a design that can accommodate that requirement. - Material Compatibility Select materials that can withstand the characteristics of the fluid being processed, including temperature, pressure, and corrosion resistance. - Maintenance Consider ease of access for cleaning and replacement during the design phase to minimize downtime.

Conclusion

Strainer flanges are fundamental components in many industrial processes, providing essential filtration that protects critical systems and enhances efficiency. By understanding the different types and their applications, industries can make informed decisions that lead to improved operational performance and reduced costs. Whether in oil and gas, water treatment, or other sectors, investing in the right strainer flange can yield significant long-term benefits.

-

Welding Table Cast Iron Surface Finish GuideNewsJul.01,2025

-

Valve Types for Industrial ApplicationsNewsJul.01,2025

-

Types of Strainer for Industrial ApplicationsNewsJul.01,2025

-

Types of Bore Gauge for Precision MachiningNewsJul.01,2025

-

Safety Standards in Welding Fabrication Table Manufacturing ProcessesNewsJun.30,2025

-

Impact of Temperature Fluctuations on Ring Gauge AccuracyNewsJun.30,2025

Related PRODUCTS