ຕ.ລ. . 16, 2024 18:03 Back to list

stop check valve

The Importance of Stop Check Valves in Industrial Applications

Stop check valves are essential components in various industrial systems, primarily serving to prevent backflow while also allowing for the shut-off of fluid flow when necessary. This dual function is crucial for maintaining system integrity and safety. Understanding the significance of stop check valves can help industries optimize their operations and prevent potential hazards.

A stop check valve combines two distinct functionalities a check valve and a stop valve. The check valve aspect allows for the flow of fluid in one direction while preventing reverse flow, which can be detrimental to system efficiency and safety. On the other hand, the stop valve feature enables operators to halt flow entirely for maintenance or repairs without disrupting the entire system. This makes stop check valves indispensable in applications where system reliability and user safety are paramount.

Industries such as oil and gas, water treatment, and chemical processing frequently utilize stop check valves

. In these sectors, the management of pressurized fluids is crucial, and any unsanctioned backflow can lead to equipment damage, contamination, or workplace hazards. By installing stop check valves in critical locations, operators can safeguard their systems against these risks.stop check valve

The design of stop check valves also plays a vital role in their efficacy. Most commonly, they are built in a globe or gate configuration, allowing for minimal pressure drop while ensuring reliable operation. Materials used in construction, such as stainless steel, bronze, or PVC, are chosen based on the specific fluid’s characteristics to withstand corrosion and wear. As technology advances, some stop check valves are now equipped with smart sensors to monitor flow rates and alert users to any irregularities, enhancing proactive maintenance strategies.

Additionally, the installation and maintenance of stop check valves are crucial consideration points. Proper installation ensures that the valve functions correctly, with the flow direction clearly marked. Regular maintenance checks help identify wear and tear, preventing unexpected failures that can lead to costly downtimes. Operators must remain vigilant about these components, as neglect can compromise not only the equipment but also the safety of personnel involved.

In conclusion, stop check valves are critical to ensuring the safe and efficient operation of various industrial systems. Their ability to provide both flow control and backflow prevention makes them invaluable in safeguarding equipment and personnel. As industries continue to evolve, the role of these valves will undoubtedly expand, further emphasizing the need for their integration into modern systems. Investing in quality stop check valves and adhering to proper maintenance practices is essential for any operation reliant on fluid transport.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

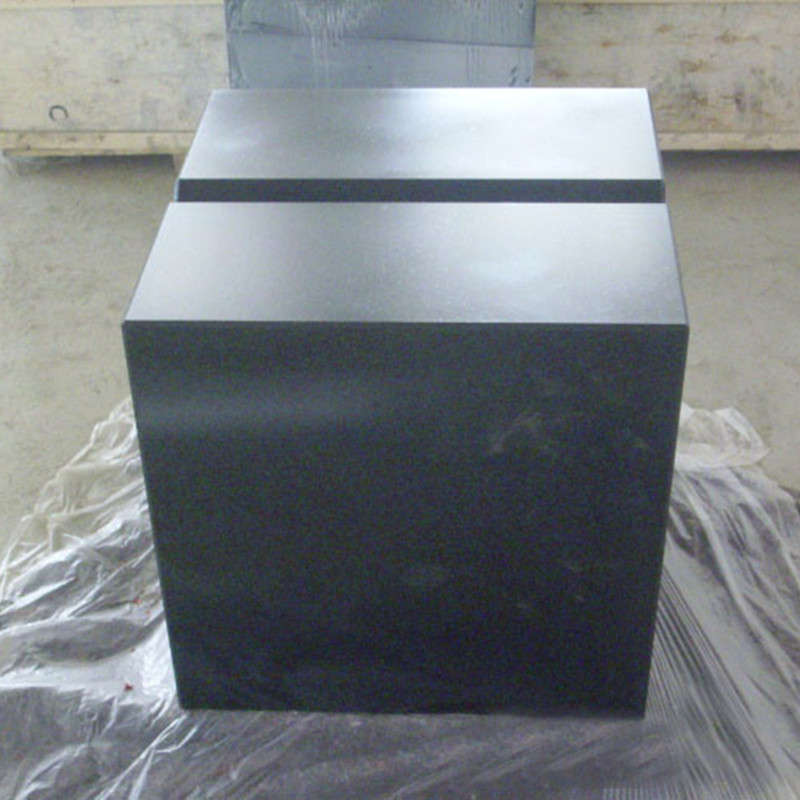

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS