ພ.ຈ. . 10, 2024 03:40 Back to list

Exploring the Benefits and Applications of Small Bore Gauges in Precision Measurement

Understanding Small Bore Gauges Precision Tools for Measurement

In the world of engineering and manufacturing, precision is paramount. Every millimeter, every micron, counts when it comes to ensuring quality and accuracy in products. One tool that plays a critical role in achieving these standards is the small bore gauge. This device is a true marvel of engineering, designed to measure the internal diameters of small holes with remarkable accuracy.

What is a Small Bore Gauge?

A small bore gauge, also known as a small diameter gauge, is an instrument used to measure the internal dimensions of small bores, tubes, and holes. Unlike other measuring tools such as calipers or micrometers, which are typically used for larger objects, small bore gauges are specifically designed to handle the intricacies and challenges of measuring confined spaces. This makes them essential in various industries, including automotive, aerospace, and medical manufacturing, where precision is critical.

Design and Functionality

The design of a small bore gauge is tailored to fit into restricted spaces, often featuring a slender probe that can be inserted into holes or tubes of varying diameters. Typical small bore gauges can measure internal diameters ranging from just a few millimeters to several centimeters.

Most small bore gauges operate on a similar principle. They employ a mechanical or electronic mechanism that captures the internal diameter of a bore by using a calibrated measuring head. The measurement results can be displayed digitally or read off a scale, depending on whether the gauge is manual or digital.

Types of Small Bore Gauges

1. Mechanical Small Bore Gauges These gauges typically use a dial indicator to display measurements. The user inserts the probe into the bore, and then the gauge's anvil provides a reading based on the internal diameter. They are durable and do not require a power source, making them suitable for harsh environments.

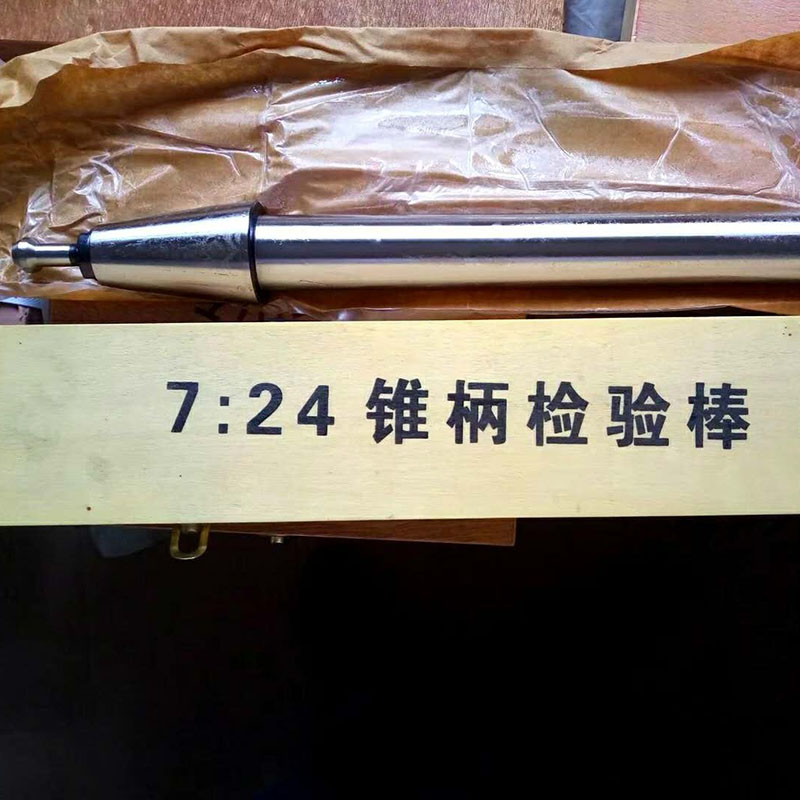

small bore gauge

2. Digital Small Bore Gauges These modern gauges feature electronic components that provide a digital readout of the measurements. They often come with additional features such as data storage, connectivity to computers for data analysis, and even built-in calibration systems to ensure accuracy.

3. Go/No-Go Gauges These specialized small bore gauges help quickly determine if a bore is within acceptable limits. They have two ends one meant to fit into the hole if it meets specifications (Go) and the other that will not fit if it's too large (No-Go).

Applications of Small Bore Gauges

The applications for small bore gauges are vast. In the automotive industry, they are used to ensure that the internal dimensions of components such as engines and fuel injectors are within required tolerances. The aerospace industry relies on them to check critical parts for aircraft, where even the slightest deviation can compromise safety. In the medical field, small bore gauges help measure the internal dimensions of surgical instruments and implants, where precision can significantly affect patient outcomes.

Advantages of Using Small Bore Gauges

One of the primary advantages of using small bore gauges is their precision. These tools can provide measurements with a tolerance of a few microns, making them invaluable in high-precision environments. Additionally, they are time-efficient, allowing for quick measurements that streamline production schedules.

Furthermore, small bore gauges are relatively easy to use. With basic training, operators can easily learn how to use these instruments effectively, which can reduce the likelihood of measurement errors.

Conclusion

In conclusion, small bore gauges are essential tools for precise measurement in a variety of industries. Their design and functionality allow them to measure internal dimensions that would be otherwise difficult to assess. As technology continues to advance, the capabilities and accuracy of small bore gauges will only improve, paving the way for even higher standards in manufacturing and engineering. Whether you're working on a car engine or a medical device, these gauges ensure that quality and precision remain at the forefront of production processes.

-

Straight Edge Rulers: Precision and Durability for Every JobNewsMay.20,2025

-

Precision with Every Angle: Discover the Best 90 Degree Angle RulersNewsMay.20,2025

-

Precision in Every Measure: Discover the Best Parallel Rulers for SaleNewsMay.20,2025

-

Perfect Your Measurements with the Right Angle SquareNewsMay.20,2025

-

The Role of Cast Iron T Slot Plates in RoboticsNewsMay.12,2025

-

The Importance of Parallel Rulers in Mechanical EngineeringNewsMay.12,2025

Related PRODUCTS