ກ.ພ. . 04, 2025 02:17 Back to list

5 butterfly valve

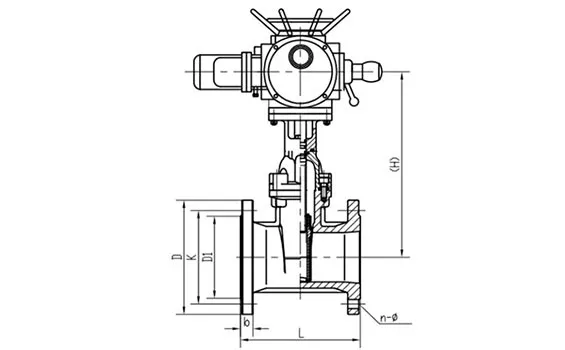

For those deeply engrossed in the engineering and industrial sectors, the 5 butterfly valve stands as a testament to innovative hydraulic control solutions. Its unique design, mechanical reliability, and ease of operation make it a linchpin in fluid control systems across various industries.

Authority in this domain comes from decades of empirical data and case studies that showcase the valve's versatility and performance. Reputable manufacturers subject their 5 butterfly valves to rigorous testing that exceeds industry standards, ensuring each valve can withstand diverse operational demands and environmental conditions. Field reports from industrial engineers consistently commend its performance, citing reduced downtime and sustained efficiency. Trust in the 5 butterfly valve is further reinforced by advanced manufacturing practices. Material selection plays a vital role in its effectiveness, with high-grade stainless steel and PTFE coatings being common selections for their resilience against corrosion and wear. Manufacturers also emphasize traceability and accountability, with many adopting ISO-certified quality management systems. This assurance of quality is crucial, particularly in critical applications such as chemical processing and water treatment facilities, where failure can lead to severe consequences. Furthermore, the 5 butterfly valve contributes to sustainability efforts within the industry. Its efficient design reduces the amount of material needed for production, while upgrades and replacements are made straightforward due to its modular nature. This aligns with the increasing demand for eco-friendly solutions in industrial processes, offering both environmental benefits and potential cost reductions. Ultimately, adopting a 5 butterfly valve in an industrial setting is more than just a choice of equipment; it is an investment in performance, reliability, and peace of mind. Its continued development and application in diverse settings speak volumes about its adaptability and the trust it commands from engineers and technicians worldwide.

Authority in this domain comes from decades of empirical data and case studies that showcase the valve's versatility and performance. Reputable manufacturers subject their 5 butterfly valves to rigorous testing that exceeds industry standards, ensuring each valve can withstand diverse operational demands and environmental conditions. Field reports from industrial engineers consistently commend its performance, citing reduced downtime and sustained efficiency. Trust in the 5 butterfly valve is further reinforced by advanced manufacturing practices. Material selection plays a vital role in its effectiveness, with high-grade stainless steel and PTFE coatings being common selections for their resilience against corrosion and wear. Manufacturers also emphasize traceability and accountability, with many adopting ISO-certified quality management systems. This assurance of quality is crucial, particularly in critical applications such as chemical processing and water treatment facilities, where failure can lead to severe consequences. Furthermore, the 5 butterfly valve contributes to sustainability efforts within the industry. Its efficient design reduces the amount of material needed for production, while upgrades and replacements are made straightforward due to its modular nature. This aligns with the increasing demand for eco-friendly solutions in industrial processes, offering both environmental benefits and potential cost reductions. Ultimately, adopting a 5 butterfly valve in an industrial setting is more than just a choice of equipment; it is an investment in performance, reliability, and peace of mind. Its continued development and application in diverse settings speak volumes about its adaptability and the trust it commands from engineers and technicians worldwide.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS