ຕ.ລ. . 11, 2024 12:16 Back to list

5 8 welding table clamps

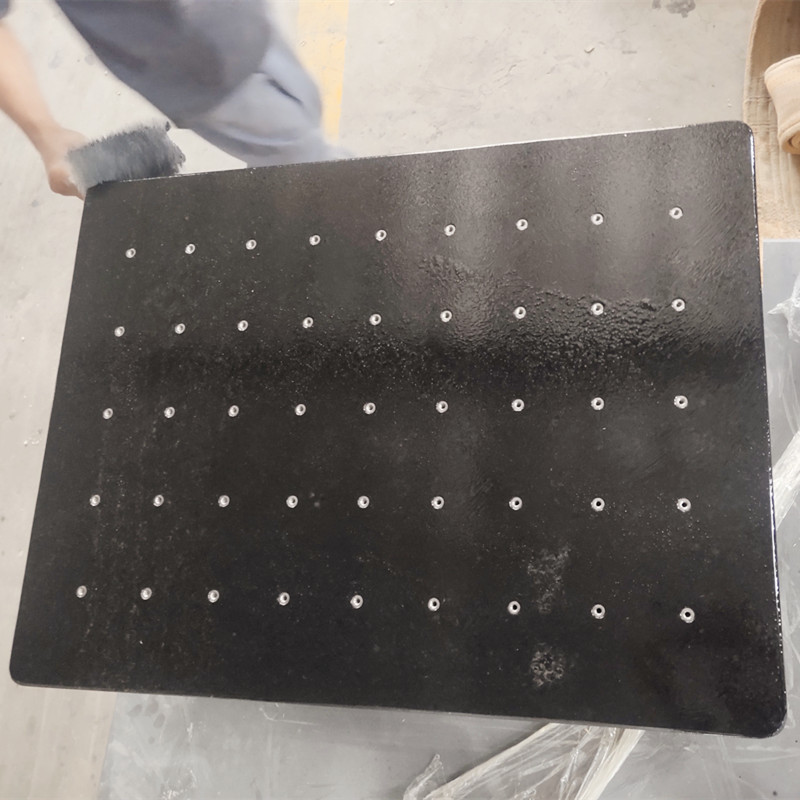

The Importance of 5 8% Welding Table Clamps in Metal Fabrication

In the realm of metal fabrication, precision and stability are paramount. Whether you are constructing intricate structures or performing simple repairs, the tools you choose can make a significant difference in the quality of your work. Among these essential tools are welding table clamps, with the 5 8% model gaining particular attention among professionals and enthusiasts alike.

Understanding Welding Table Clamps

Welding table clamps are designed to hold metal pieces securely in place during the welding process. They facilitate the accurate alignment of workpieces, thereby minimizing misalignment or distortion that may occur from the heat generated during welding. The 5 8% welding table clamps, known for their robust construction and reliability, are engineered to withstand the rigors of metal working.

Design and Features

The 5 8% welding table clamps boast a unique design that enhances their functionality. Made from high-strength materials, these clamps offer excellent durability, ensuring they can handle the demands of heavy-duty applications. Their adjustable design allows them to accommodate various metal thicknesses, providing versatility for different projects. Additionally, the ergonomic handle design ensures a comfortable grip, enabling users to apply the required clamping force with ease.

One of the standout features of the 5 8% clamps is their quick-release mechanism. This feature allows fabricators to rapidly adjust or remove clamps without wasting precious time, aiding in the efficiency of any welding operation. The clamps are also equipped with rubber pads, which prevent damage to the workpieces and reduce slippage, ensuring a firm hold without marring the metal surfaces.

Benefits in the Welding Process

5 8 welding table clamps

The use of welding table clamps such as the 5 8% significantly enhances the welding process. First and foremost, they provide stability, which is crucial for achieving accurate welds. When metal pieces are securely clamped, welders can focus on their technique rather than worrying about the alignment of their workpieces. This added stability reduces the risk of flaws in the weld, leading to stronger and more reliable joints.

Moreover, the use of these clamps can improve safety in the workshop. By firmly securing materials, the likelihood of pieces shifting unexpectedly decreases, minimizing the risk of accidents. This is particularly important in environments where multiple workers are present and where heavy equipment is in use.

Practical Applications

The 5 8% welding table clamps find applications in various sectors, from automotive repair to industrial fabrication. In automotive workshops, for example, these clamps are indispensable when aligning chassis components or performing bodywork. In industrial settings, they are vital for fabricating large structures, such as frames for machinery or infrastructure components, ensuring everything is correctly aligned before welding.

Hobbyists also reap the benefits of these clamps in home workshops. Whether crafting metal sculptures or building custom furniture, reliable clamping solutions enhance the quality and precision of their projects. The affordability and availability of the 5 8% clamps make them an attractive option for both professionals and DIY enthusiasts.

Conclusion

In conclusion, the 5 8% welding table clamps offer a myriad of benefits that significantly enhance the welding process. Their durable construction, ergonomic design, and quick-release features make them a preferred choice for fabricators across various fields. By ensuring stability and safety, these clamps contribute to achieving high-quality welds and successful projects. For anyone involved in metal fabrication, investing in reliable welding table clamps like the 5 8% is a step towards improved efficiency and superior craftsmanship. Whether you’re a seasoned professional or an eager beginner, these clamps will undoubtedly elevate your welding experience.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS