Nov . 02, 2024 06:02 Back to list

spline gauge

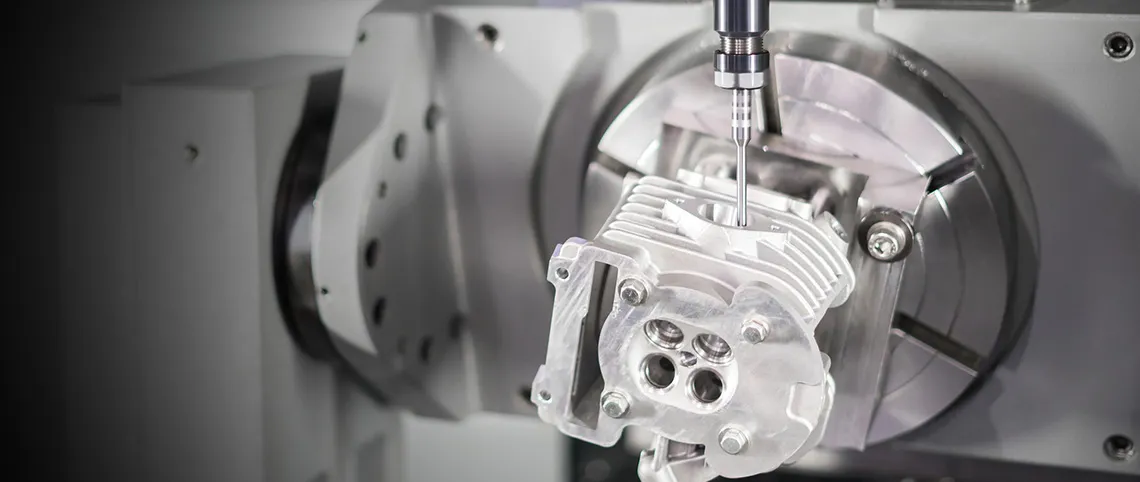

Understanding the Spline Gauge A Precision Tool in Engineering

In the world of precision engineering and manufacturing, the need for accurate measurements cannot be overstated. One of the tools that play a crucial role in ensuring this precision is the spline gauge. The spline gauge is an instrument specifically designed to measure the angles and profiles of spline shafts, which are non-circular features used extensively in automotive and mechanical applications.

A spline is defined as a series of ridges or teeth on a shaft that fit into corresponding grooves on a mating part. This design allows for the transmission of torque while also enabling parts to be easily assembled and disassembled. The engagement between the spline and its counterpart must be precise, as any misalignment can lead to increased wear and tear, reduced efficiency, or even failure of the mechanism.

The spline gauge offers a straightforward yet effective solution for checking the accuracy of spline dimensions. It typically comes with a series of notched blades or templates that correspond to standard spline profiles. By placing the gauge against the spline, engineers and technicians can easily verify that the profile matches the specified dimensions. This verification process is essential in quality control during manufacturing processes and during routine maintenance checks.

One of the significant advantages of using a spline gauge is its simplicity and ease of use

. Unlike more complex measurement tools, spline gauges require minimal training and can yield immediate results. They are particularly valuable in environments where quick assessments are necessary, such as in automotive diagnostics or in manufacturing assembly lines.spline gauge

Different types of spline gauges are available, depending on the specific application. These can range from simple manual gauges to intricate digital gauges that provide numerical readouts. Digital spline gauges often incorporate advanced technology such as laser measurement, allowing for even higher precision and ease of use. These tools can eliminate human error in measurement and offer automated data logging for record-keeping and analysis.

In addition to their role in quality control, spline gauges have educational value. They provide students and aspiring engineers with hands-on experience in measurement techniques and an understanding of the importance of tolerances in engineering design. By using spline gauges, students learn to appreciate the nuances of mechanical systems and the significance of precise component interactions.

As industries continue to evolve, with advancements in materials and manufacturing techniques, the precision requirements for components like splines are becoming more stringent. Consequently, the role of the spline gauge will remain pivotal in ensuring that these components adhere to the highest standards of quality and performance.

In conclusion, the spline gauge is an indispensable tool in the realm of precision measurement. Its ability to ensure the correct profile and alignment of splines contributes significantly to the reliability and efficiency of a broad range of mechanical systems. As technology advances, the spline gauge will continue to adapt and evolve, but its fundamental purpose of safeguarding accuracy in engineering will remain vital for the foreseeable future.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS