Oct . 13, 2024 10:09 Back to list

150 Globe Valve Specifications and Applications for Industrial Use and Efficiency

Understanding Globe Valves A Comprehensive Overview

Globe valves are pivotal components in fluid control systems, serving a critical role across various industries, including water supply, wastewater treatment, oil and gas, and power generation. Among the diverse types of globe valves, the designation 150 typically refers to the valve's pressure class, indicating its suitability for specific pressure ratings within different applications.

What is a Globe Valve?

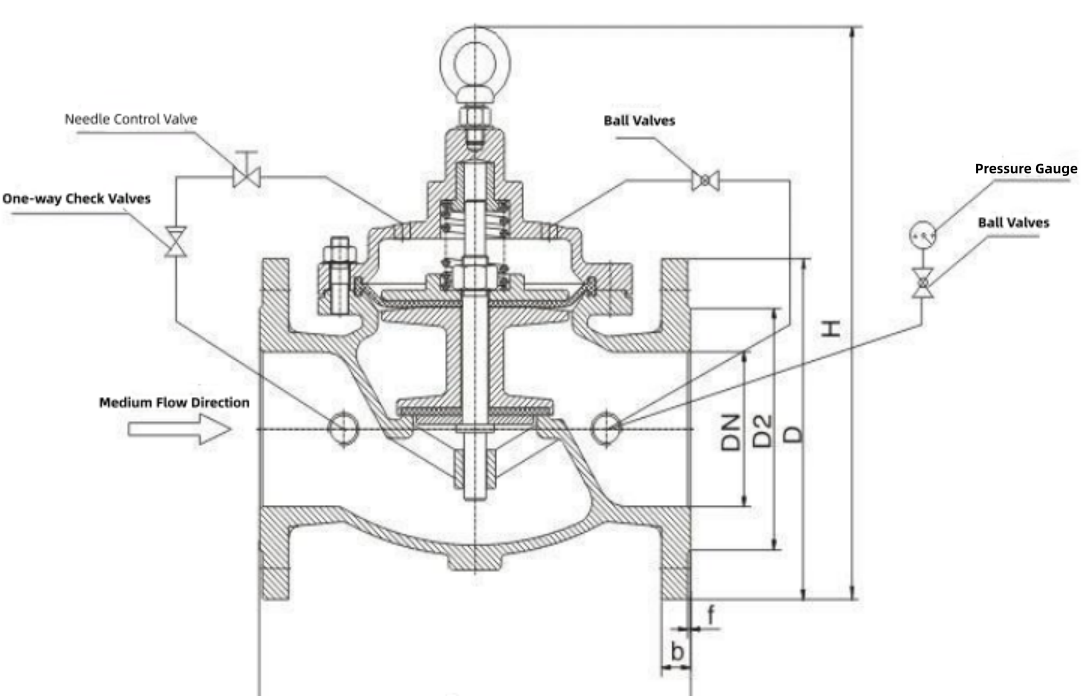

A globe valve is a type of valve used to regulate fluid flow in pipelines. Its name is derived from the spherical body shape that contains an internal baffle or disc to control the flow of the medium. This design allows for significant throttling capabilities, making globe valves an ideal choice for applications requiring precise flow regulation.

The valve operates by raising and lowering a disc, which sits perpendicular to the flow of fluid. When the valve is fully opened, the disc is lifted completely out of the flow path, allowing for unrestricted movement of the fluid. Conversely, when the valve is closed, the disc seats against a ring to block the flow entirely.

Applications of Globe Valves

Globe valves are widely used in industries where accurate control of fluid flow is essential. Common applications include

1. Water Supply Systems They are used to manage the distribution of water, maintaining optimum flow rates and pressure within municipal systems. 2. Wastewater Treatment In this setting, globe valves help regulate the flow of sewage and effluent throughout treatment processes. 3. Oil and Gas These valves are critical in controlling the flow of crude oil, natural gas, and other hydrocarbons in pipelines, refineries, and processing plants. 4. Power Generation Globe valves manage steam and cooling water flow in power plants, ensuring efficient energy production.

Advantages of Globe Valves

globe valve 150

One of the primary benefits of globe valves is their exceptional throttling capability. Unlike gate valves, which are primarily designed to be either fully open or fully closed, globe valves can be finely adjusted to regulate flow. This level of control is crucial in scenarios where maintaining specific pressure levels is required.

Moreover, globe valves provide reliable isolation capabilities, helping to prevent reverse flow and leakage. The valve’s design ensures minimal turbulence when the flow is redirected, resulting in lower pressure drops compared to other valve types.

Design Features and Considerations

When discussing globe valves, it is essential to consider various design features, especially those pertaining to the 150 designation. This typically indicates that the valve is designed to withstand pressures up to 150 psi (pounds per square inch). The material, size, and source of the valve can also influence its operational capabilities, durability, and suitability for specific applications.

Common materials for globe valves include cast iron, stainless steel, brass, and plastic, depending on the fluid type and operational environment. Each material has unique properties that influence the valve’s performance in terms of corrosion resistance, temperature tolerance, and overall lifespan.

Maintenance and Troubleshooting

Proper maintenance of globe valves is crucial for ensuring their longevity and performance. Regular inspection and cleaning can help prevent issues such as corrosion or build-up that may impede the valve's operation. If a globe valve shows signs of malfunction, such as leaks or failure to open/close properly, troubleshooting should focus on identifying the cause. This may involve checking for wear on the seat and disc, ensuring that the actuator is functioning correctly, and confirming that there are no blockages in the piping system.

Conclusion

In summary, globe valves, particularly those classified as 150, are vital for managing fluid flow in numerous industrial applications. Their ability to provide precise control makes them indispensable for engineers and operators alike. Understanding the features, applications, and maintenance practices of globe valves is essential for maximizing their efficiency and prolonging their operational life. Whether you are designing a new system or maintaining an existing one, recognizing the significance of globe valves is crucial for achieving optimal performance and reliability.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS