Oct . 14, 2024 20:42 Back to list

Custom Fabricated Welding Tables for Enhanced Efficiency and Precision in Metalwork

Custom Built Welding Tables Enhancing Efficiency and Precision in Metalworking

Welding is a critical process in various industries, from automotive to construction, and having the right equipment can significantly improve workflow and output. One of the most essential pieces of equipment for any professional welder is a high-quality welding table. While off-the-shelf options exist, many skilled craftsmen have turned to custom built welding tables to meet their specialized needs. These tailor-made solutions not only enhance efficiency but also ensure precision in every weld.

Why Choose Custom Built Welding Tables?

1. Tailored Design for Specific Needs Every welding project is unique. Standard tables may lack the features necessary for specific applications, making custom built tables an attractive option. Welders can design their tables to accommodate the size of the materials they frequently work with, the types of welds they perform, and the specific tools they use. This customization means fewer adjustments during the welding process and more time spent on actual work.

2. Enhanced Durability and Stability One of the primary concerns in welding is the stability of the workspace. Custom tables can be built with sturdier materials, reinforced frames, and specific weight distributions to ensure they can handle heavy materials and rigorous use. The stability of a welding table affects the quality of the welds produced; a shaky table can lead to uneven welding, misalignments, and ultimately compromised integrity in the finished product.

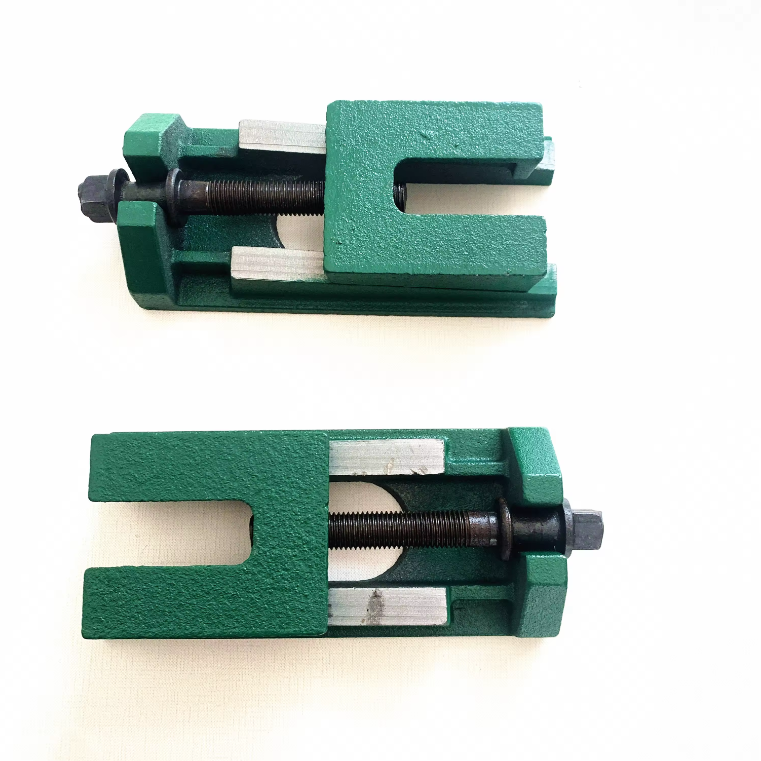

3. Safety Features Safety is paramount in any welding operation. Custom tables can be equipped with features that enhance safety. For example, built-in fire-resistant surfaces, safety clamps for securing materials, or even proper grounding systems can be integrated into the design. By addressing safety concerns from the outset, custom welding tables can significantly reduce the risk of accidents in the workshop.

custom built welding tables

4. Incorporation of Integrated Tools and Accessories Custom tables allow for the integration of various tools and accessories, creating a comprehensive workspace. Features like adjustable clamps, built-in tool storage, and modular components can be seamlessly incorporated into the table. This organization saves time and enhances efficiency, as welders have everything they need at their fingertips, reducing the need to search for tools or adjust setups mid-project.

5. Optimized Workflow A well-designed custom welding table can streamline the entire welding process. By placing tools, storage, and work surfaces in strategic locations, aspects of the workflow can be optimized. For instance, a cutting station can be integrated alongside the welding area, allowing for a smooth transition from cutting to welding. This optimized layout can facilitate faster project completion, enhance accuracy, and minimize errors.

6. Aesthetic Appeal While functionality is paramount, aesthetics should not be disregarded. Custom built welding tables can reflect the individuality of the welder or the brand of the company. A well-crafted, attractive table can create a professional environment that boosts morale and encourages pride in workmanship.

Conclusion

In the field of welding, where precision, safety, and efficiency are crucial, custom built welding tables offer unparalleled advantages. By considering personalized designs, enhanced durability, optimized workflow, and incorporating essential safety features, welders can significantly improve their productivity and the quality of their work. Choosing custom over standard solutions ensures that the unique demands of each project are met while providing a workspace that inspires confidence and excellence. Therefore, for professionals looking to elevate their welding capabilities, investing in a custom built welding table is a decision that pays dividends in the long run. As the welding industry continues to evolve, embracing innovation through personalization will undoubtedly lead to enhanced craftsmanship and a new standard of excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS