Mar . 06, 2025 13:54 Back to list

guide rail types

Guide rails are indispensable in modern industrial and safety systems, ensuring stability and precision in environments ranging from high-speed elevators to robust manufacturing systems. They come in various types, each tailored to specific needs and applications, making it crucial to understand their distinct characteristics. Below, we explore the diverse types of guide rails and their respective uses, focusing on authenticity, professional insight, and authority.

Transitioning to more niche applications, the Ball Bearing Rails provide exceptional capability in stress-bearing applications. Their unique design excels in scenarios calling for both horizontal and vertical mobility, making them a staple in heavy industrial machinery. Technicians and operators alike trust these rails for maintaining performance under extreme pressure, attributing to their ingenious design that separates load-bearings and paths, mitigating stress concentrations. Crowned Roller Rails offer precision in applications subjected to angular misalignment. Often integrated into conveyor systems, their self-centering ability prevents drifting and ensures the product flow remains uninterrupted. Logistics professionals advocate their use in complex transport systems where alignment issues could lead to operational delays. The crowned design automatically guides components to the center, showcasing another level of sophistication in rail technology. Not to be overlooked are Custom Guide Rails, engineered expressly to meet unique industry specifications. Innovation thrives in this category, as manufacturers collaborate with engineers to tailor materials, dimensions, and load capacities, catering to specialized projects. The uniqueness of custom solutions lies in their adaptability, often driving breakthroughs in fields like biotechnology and specialized automation processes. In projecting the expertise required to optimize these systems, it becomes apparent that professional guidance and experience are foundational. Collaboration with engineers and specialists not only ensures the right rail solution but also harnesses advancements in material science and engineering. By leveraging the latest insights and industrial practices, organizations can attain unprecedented precision and efficiency. Guide rails power the backbone of innumerable systems, and understanding their types bridges the gap between basic functionality and exceptional performance. With a focus on reliability, safety, and expert implementation, they continue to underscore their relevance in driving forward our technological ambitions. This detailed exploration affirms their indispensable role in advancing industrial capabilities, reflecting a synthesis of hands-on experience, authoritative knowledge, and enduring trustworthiness in engineering innovations.

Transitioning to more niche applications, the Ball Bearing Rails provide exceptional capability in stress-bearing applications. Their unique design excels in scenarios calling for both horizontal and vertical mobility, making them a staple in heavy industrial machinery. Technicians and operators alike trust these rails for maintaining performance under extreme pressure, attributing to their ingenious design that separates load-bearings and paths, mitigating stress concentrations. Crowned Roller Rails offer precision in applications subjected to angular misalignment. Often integrated into conveyor systems, their self-centering ability prevents drifting and ensures the product flow remains uninterrupted. Logistics professionals advocate their use in complex transport systems where alignment issues could lead to operational delays. The crowned design automatically guides components to the center, showcasing another level of sophistication in rail technology. Not to be overlooked are Custom Guide Rails, engineered expressly to meet unique industry specifications. Innovation thrives in this category, as manufacturers collaborate with engineers to tailor materials, dimensions, and load capacities, catering to specialized projects. The uniqueness of custom solutions lies in their adaptability, often driving breakthroughs in fields like biotechnology and specialized automation processes. In projecting the expertise required to optimize these systems, it becomes apparent that professional guidance and experience are foundational. Collaboration with engineers and specialists not only ensures the right rail solution but also harnesses advancements in material science and engineering. By leveraging the latest insights and industrial practices, organizations can attain unprecedented precision and efficiency. Guide rails power the backbone of innumerable systems, and understanding their types bridges the gap between basic functionality and exceptional performance. With a focus on reliability, safety, and expert implementation, they continue to underscore their relevance in driving forward our technological ambitions. This detailed exploration affirms their indispensable role in advancing industrial capabilities, reflecting a synthesis of hands-on experience, authoritative knowledge, and enduring trustworthiness in engineering innovations.

Next:

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

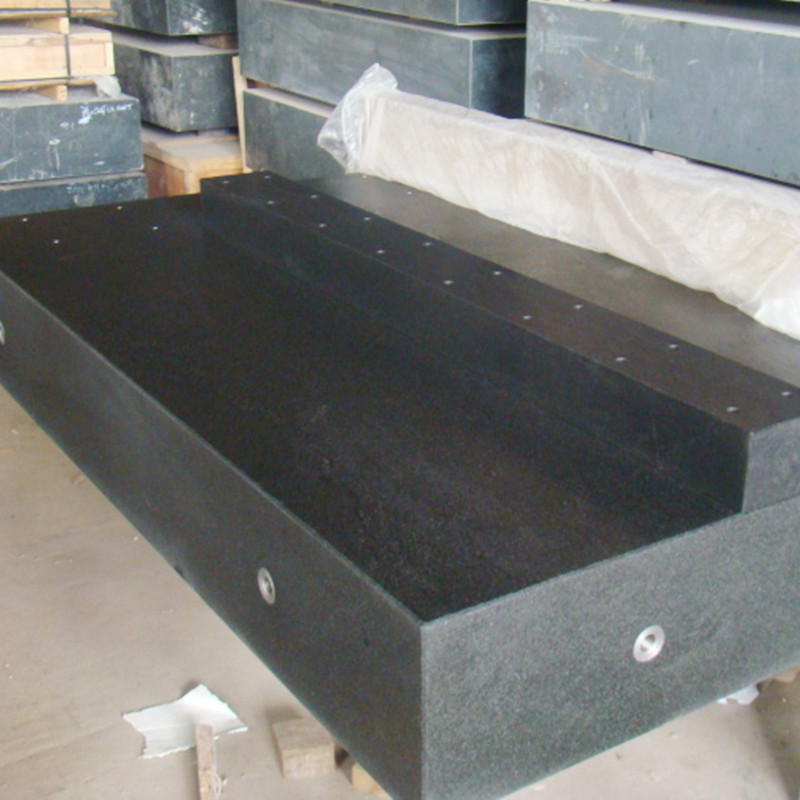

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS