تشرینی یەکەم . 31, 2024 13:38 Vegere navnîşê

Magnetic V Block Uses

In the world of precision machining and manufacturing, accuracy and stability are paramount. One tool that stands out in ensuring these qualities is the magnetic V block. With versatile applications across various industries, including metalworking, woodworking, and assembly, these tools are essential for anyone looking to achieve precision in their work. In this blog post, we will delve into the various magnetic V block uses and why they are indispensable for professionals and hobbyists alike.

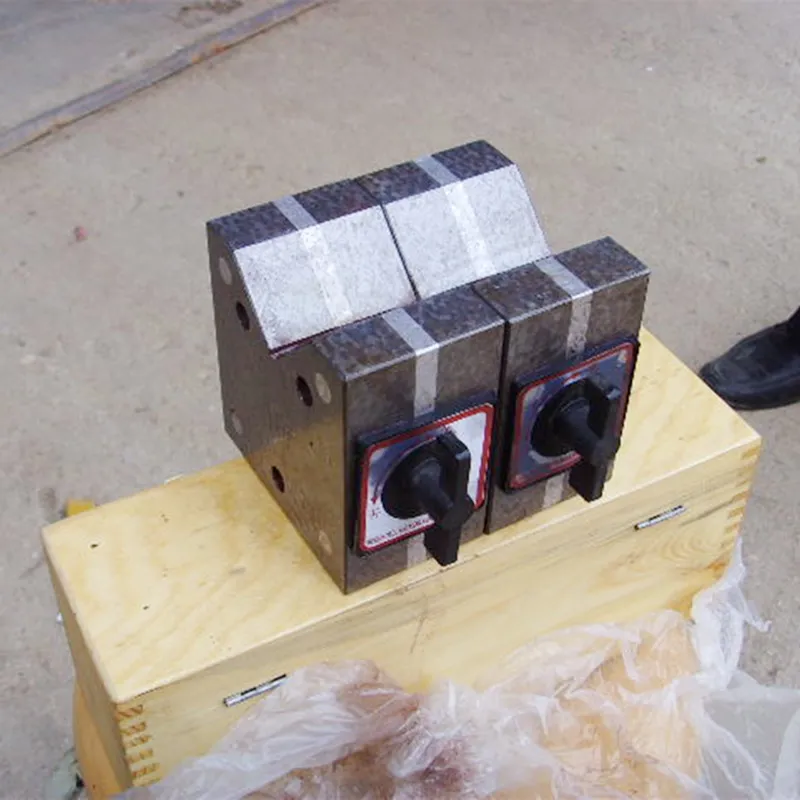

What is a Magnetic V Block?

A magnetic V block is an instrument designed with a V-shaped groove, typically used to hold cylindrical or flat workpieces securely during machining processes. The block is equipped with a powerful magnet that provides a firm grip, allowing operators to work hands-free, thus improving efficiency and safety. These blocks come in different sizes and designs, catering to various applications.

Key Uses of Magnetic V Blocks

1. Precision Machining

One of the primary magnetic V block uses is in precision machining. Whether it’s milling, grinding, or drilling, a magnetic V block holds workpieces firmly in place, allowing for accurate cuts and finishes. The stability provided by the magnetic base minimizes vibrations, which is crucial for achieving tight tolerances in precision engineering.

2. Assembly Work

In assembly work, particularly in the automotive and aerospace industries, utilizing a magnetic V block can streamline processes by securely holding components during assembly. This ensures that parts are aligned correctly and reduces the chances of errors, which can be costly in terms of both time and resources.

3. Inspection and Testing

Quality control is vital in manufacturing, and magnetic V blocks play a significant role in inspection processes. They hold parts steady for precise measurements using calipers, gauges, or other inspection tools. The magnetic feature allows for quick setup and repositioning, which enhances productivity during inspection.

4. Welding Applications

When it comes to welding, stability is key to ensuring solid welds. A magnetic V block can be used to hold metal pieces at the correct angle, allowing welders to focus on the quality of their work without worrying about maintaining the position of the materials.

5. Woodworking Projects

While commonly associated with metalworking, **magnetic V blocks** also find utility in woodworking. They assist woodworkers in routing, sanding, or cutting angles accurately by providing a secure hold on wooden pieces, facilitating more intricate designs and construction.

6. Customization in Tooling

For industries that require specialized tooling or setups, magnetic V blocks can be customized to fit specific project needs. This adaptability makes them a valuable tool in any technician's arsenal, capable of accommodating a wide range of applications.

The magnetic V block is an invaluable tool in various industries, providing stability and precision when it matters most. Whether you're involved in machining, assembly, or quality control, understanding the different magnetic V block uses can significantly enhance your workflow. Investing in high-quality magnetic V blocks not only ensures accurate work but also boosts overall productivity. Embrace the versatility of this tool and take your projects to the next level!

If you're interested in learning more about magnetic V blocks and their applications, feel free to reach out or check our comprehensive range of products tailored to your needs.

-

Thread Plug Gauge Requires Careful HandlingNûçeJul.29,2025

-

Surface plate calibrationNûçeJul.29,2025

-

Ring Gauge Ensures Machining AccuracyNûçeJul.29,2025

-

Pad Iron Reinforces Anchor PointsNûçeJul.29,2025

-

Ground anchor stabilizes embankmentsNûçeJul.29,2025

-

Granite Box Maintains Precision FlatnessNûçeJul.29,2025

Berhemên Têkildar