تشرینی دووەم . 07, 2024 15:36 Back to list

Stainless Steel Body Butterfly Valve for Reliable Flow Control Solutions

The Versatility and Advantages of Stainless Steel Butterfly Valves

Butterfly valves are essential components in various industrial applications, providing reliable flow regulation, on-off control, and isolation capabilities. When these valves are constructed with a stainless steel body, the advantages become even more pronounced, making them a popular choice in numerous sectors, including water treatment, chemical processing, and oil and gas industries. In this article, we will delve into the characteristics, benefits, and applications of stainless steel butterfly valves.

Understanding Butterfly Valves

A butterfly valve is designed with a disk that rotates around a central axis, allowing the valve to either open or close, thereby regulating fluid flow. The simplicity of its design leads to a compact and lightweight structure, which is advantageous in many installations. Butterfly valves are also renowned for their quick operation; a quarter turn is all it takes to go from fully closed to fully open, improving efficiency in processes where speed is essential.

The Significance of Stainless Steel

Stainless steel is a favored material in valve construction due to its exceptional properties, including corrosion resistance, strength, and hygiene. The alloying of steel with chromium grants it the ability to resist rust and tarnishing, making it ideal for applications exposed to harsh environments, such as chemical and wastewater treatment.

The use of stainless steel in butterfly valves not only enhances durability but also ensures longevity. This is particularly important in industries where downtime can result in significant economic losses. Additionally, stainless steel butterfly valves often require less maintenance than their counterparts made from other materials, contributing to lower operational costs over time.

Advantages of Stainless Steel Butterfly Valves

1. Corrosion Resistance The foremost advantage of stainless steel is its resistance to corrosion. Valve systems often encounter different types of fluids that may contain corrosive agents. In such cases, a stainless steel body can withstand harsh conditions without degrading, ensuring a reliable and safe operation.

2. Strength and Durability Stainless steel is known for its high tensile strength, making stainless steel butterfly valves robust and capable of handling high-pressure applications. Their durability enables them to maintain performance standards even under extreme operating conditions.

3. Hygienic Properties In industries such as food processing and pharmaceuticals, hygiene is paramount. Stainless steel does not harbor bacteria, making these valves suitable for sanitary applications where cleanliness is essential.

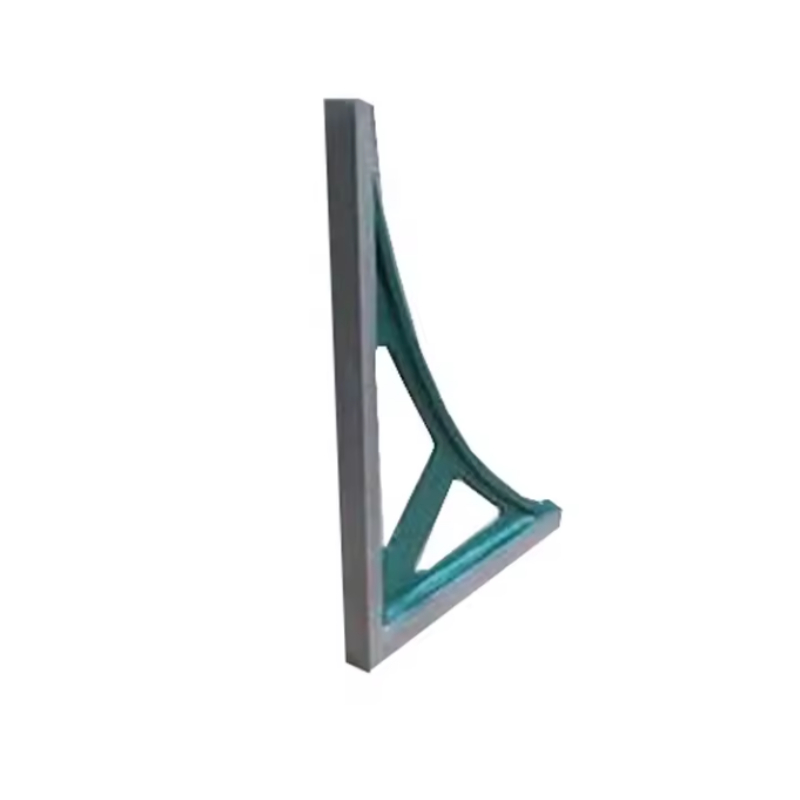

butterfly valve stainless steel body

4. Low Friction and Easy Operation The design of butterfly valves promotes minimal friction when opening and closing. This feature not only enhances operational efficiency but also reduces wear and tear on the valve components, prolonging their lifespan.

5. Versatility Stainless steel butterfly valves can be used in various applications, from controlling the flow of water and gases to handling corrosive chemicals. Their ability to adapt to diverse environments makes them a versatile component in any industrial setup.

Applications of Stainless Steel Butterfly Valves

Stainless steel butterfly valves find applications across numerous sectors, including

- Water Treatment Plants They are used for regulating flow in municipal and industrial water systems, ensuring effective control and minimal leakage.

- Chemical Processing Their resistance to corrosive substances makes stainless steel butterfly valves ideal for chemical applications, where harsh materials are the norm.

- Oil and Gas Industry They are employed in pipelines to control the flow of hydrocarbons, thanks to their durability and reliability.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves regulate air and water flow, enhancing energy efficiency and system performance.

Conclusion

Stainless steel body butterfly valves offer numerous advantages that make them a vital choice in various industrial applications. Their corrosion resistance, strength, and ease of maintenance ensure that they perform reliably in challenging environments, thereby optimizing operational efficiency and reducing costs. As industries continue to seek durable and efficient solutions, the role of stainless steel butterfly valves will remain pivotal in achieving those objectives. Whether in water treatment, chemical processing, or oil and gas operations, these valves stand out as a testament to engineering excellence.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS