제품 설명

마그네시아 알루미늄 통치자는 주로 산업 분야에 따라 중공업 통치자와 경공업 통치자의 두 가지 유형으로 나뉩니다. 중공업 자는 대부분 주철 및 주강 소재로 제작되는 반면, 경공업 자는 대부분 마그네슘알루미늄, 합금강, 스테인리스강 등의 재질로 제작됩니다. 마그네슘 알루미늄 눈금자의 특정 모양과 모델은 실제 필요에 따라 설계할 수 있습니다.

마그네슘 알루미늄 눈금자 포인트:

- 1. 마그네슘 알루미늄 자의 적용 : 섬유 기계의 설치, 레벨링, 유지 보수 및 측정.

- 2. 마그네슘 알루미늄 자는 가볍습니다. 3m 길이의 자 무게는 9kg에 불과합니다.

- 3. 마그네슘 알루미늄 눈금자는 사용하기 편리합니다. 6미터 길이의 눈금자를 사용하면 작업자가 쉽게 이동하고 측정할 수 있습니다.

- 4. 마그네슘 알루미늄 눈금자는 쉽게 변형되지 않습니다. 일반 철강 재료의 굽힘 점은 30kg/mm2이고 일반 주철 부품의 굽힘 점은 38kg/mm2입니다. 이 소재의 굽힘점은 110kg/mm2에 달하며 굽힘 저항 지수는 다른 소재를 훨씬 능가합니다.

- 5. 마그네슘 알루미늄 눈금자는 보관하기 쉽습니다. 걸거나 평평하게 놓을 수 있으며 직진성과 평행도는 장기간 평평한 배치에 영향을 받지 않습니다.

- 6. 마그네슘 알루미늄 눈금자는 녹슬기 쉽지 않습니다. 사용 중에 기름을 바르지 말고 장시간 사용하지 말고 보관할 때 일반 산업용 기름을 얇게 바르십시오.

원산지 : 중국 허베이

보증 기간: 1년

맞춤형 지원: OEM, ODM, OBM

브랜드명 : 스토란

모델 번호 : 3002

재질 : 알루미늄 마그네슘 합금

정확도 : 맞춤형

작동 모드: 맞춤형

품목 무게 : 맞춤형

용량 : 맞춤형

재질 : 재질 알루미늄 마그네슘 합금

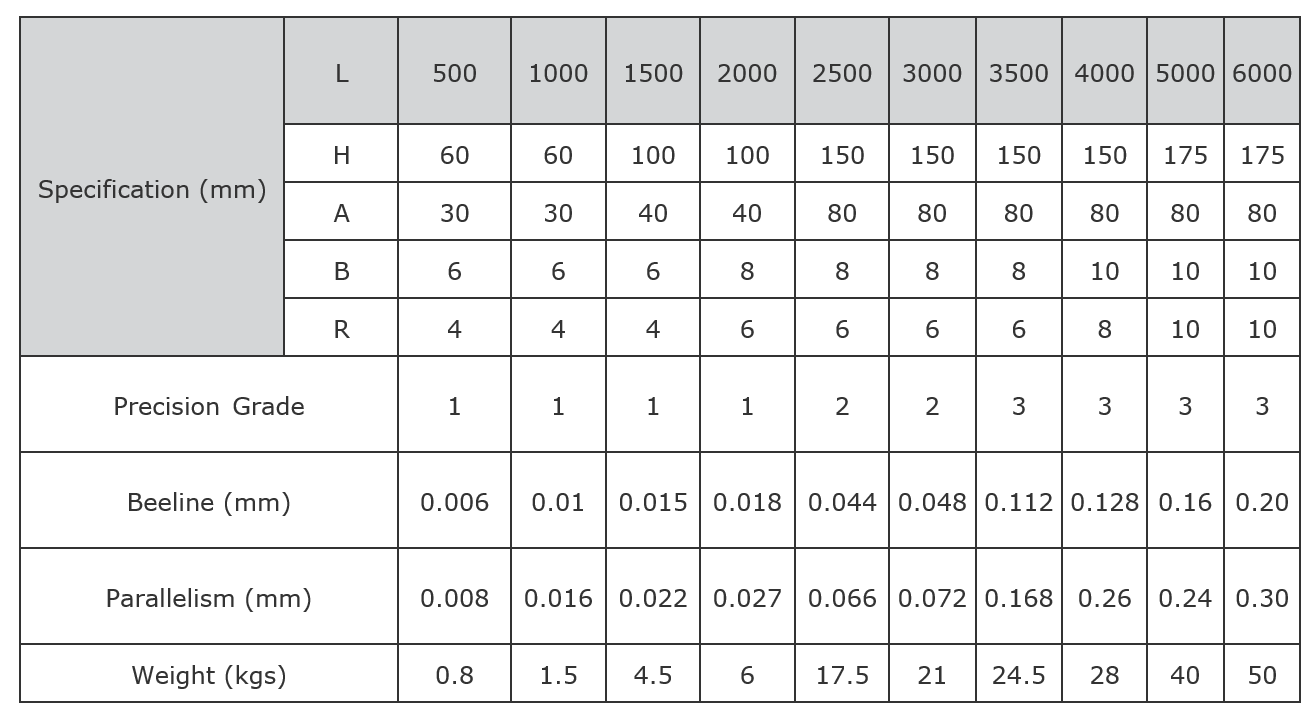

사양: 첨부된 양식을 참조하거나 맞춤 설정하세요.

물리적 성능: 47kg/mm

확장성: 17%

항복점 : 110kg/mm2

Working temperature:(20±5)℃

정밀 등급 : 1-3

포장 : 합판 상자

리드타임

|

수량(개) |

1 - 1200 |

> 1200 |

|

리드타임(일) |

30 |

협상 예정 |

Magnesium Aluminum Parallel Ruler: 110kg/mm² Yield Strength for Anti-Deformation

In industrial alignment and precision measurement, the risk of ruler deformation under load can compromise accuracy—until now. Storaen’s magnesium aluminum parallel ruler combines a robust 110kg/mm² yield strength with lightweight design, delivering unmatched anti-deformation performance for applications where dimensional stability is non-negotiable. Here’s how our engineering transforms parallel ruler use in challenging environments:

1. The Science of 110kg/mm² Yield Strength

Magnesium aluminum alloy (MB15) offers a 2x strength-to-weight advantage over pure aluminum:

Load Resistance: Unlike standard aluminum rulers that bend under 50kg/mm², our rulers withstand 110kg/mm²—ideal for supporting 200kg+ workpieces during CNC machine bed calibration or textile loom installation. This prevents the 0.5mm/m sag common in weaker materials, ensuring parallelism stays within ±0.02mm/m (Grade 1 precision).

Thermal Stability: The alloy’s low coefficient of thermal expansion (21.5×10⁻⁶/°C) maintains accuracy across 10°C–40°C temperature swings, critical for outdoor construction or unheated workshops where steel rulers expand/contract unpredictably.

2. Applications Where Deformation Is Not an Option

Storaen’s magnesium aluminum parallel ruler excels in high-stakes scenarios:

CNC Machine Alignment: A 3000mm ruler with 110kg/mm² strength supports laser alignment tools during bed rail installation, ensuring 0.01mm/m parallelism for precision machining of automotive transmission cases—eliminating vibration-induced tool wear.

Textile Machinery Calibration: In loom setup, the ruler’s rigidity prevents sag when spanning 2000mm between guide rollers, maintaining ±0.05mm thread path alignment and reducing fabric defects by 30%.

Heavy Equipment Inspection: For mining machinery track alignment, the ruler’s anti-deformation design withstands accidental impacts (e.g., 5kg dropped tools) without permanent bend—unlike plastic or low-grade aluminum alternatives that require frequent replacement.

3. Design Advantages for Durability & Usability

Lightweight Rigidity: At just 3kg/m (30% lighter than steel), a 3m ruler weighs only 9kg, enabling one-person handling for elevated inspections (e.g., overhead conveyor rails) without fatigue—a key benefit for parallel ruler use in hard-to-reach areas.

Surface Protection: A 20μm anodized coating resists corrosion from coolant, oil, and humidity, extending service life by 2x compared to uncoated aluminum rulers—no need for regular anti-rust treatments.

Precision Grades: Choose Grade 1 (±0.02mm/m parallelism) for general industry or Grade 2 (±0.05mm/m) for layout tasks, both verified via laser interferometry to meet ISO 1101 standards.

4. Storaen’s Commitment to Value

Competitive Parallel Ruler Price: Starting at $299 for 500mm models, our magnesium aluminum rulers offer 3x the lifespan of generic steel tools, delivering lower total cost of ownership—especially for bulk orders in construction or manufacturing fleets.

Custom Solutions: Need a 6000mm ruler with reinforced end caps for heavy lifting? Our OEM team provides bespoke designs in 4–6 weeks, ensuring optimal load distribution for your unique parallel ruler use cases.

Warranty & Support: Backed by a 1-year warranty against deformation or coating failure, plus free calibration certificates for traceable accuracy—essential for quality audits in ISO 9001-certified facilities.

Don’t let deformation risks compromise your measurements. Storaen’s magnesium aluminum parallel ruler, with 110kg/mm² yield strength and lightweight durability, sets a new standard for industrial alignment. Whether for sale as a standalone tool or integrated into custom fixtures, our rulers ensure precision stays true under load, temperature shifts, and daily wear—making them the smart choice for professionals who demand reliability without compromise. Explore our parallel rulers for sale today and experience the Storaen difference in anti-deformation engineering.

How to Choose a Parallel Ruler: Size & Precision Grade Guide

Selecting the right parallel ruler is critical for accurate alignment and measurement in industrial applications. Whether for CNC machine calibration, textile loom setup, or heavy equipment inspection, the choice hinges on two key factors: size and precision grade—with material, durability, and cost playing supporting roles. Here’s your step-by-step guide to navigating these decisions, featuring Storaen’s engineered solutions that balance performance and value in parallel rulers for sale.

1. Size Selection: Match the Task at Hand

Choose a ruler length that suits your workpiece and parallel ruler use:

Small-Scale Tasks (≤1000mm):

500–1000mm rulers work for bench-top inspections, like verifying small machine components or electronic part alignment. Storaen’s aluminum alloy models (starting at $299) offer lightweight handling (1.5kg for 1000mm) without compromising rigidity, ideal for prototyping or low-load environments.

Mid-Range Applications (1000–3000mm):

1500–3000mm rulers are standard for CNC machine beds and textile machinery. Our magnesium aluminum parallel ruler (3kg/m weight, 110kg/mm² yield strength) spans 2000mm while resisting sag under 100kg loads, ensuring ±0.02mm/m parallelism for automotive part machining.

Large-Scale Projects (≥3000mm):

For industrial construction or aerospace assembly, 4000–6000mm rulers with reinforced ribs (available via Storaen’s OEM service) distribute weight evenly, enabling one-person use for overhead conveyor alignment without flexing.

2. Precision Grade: Align with Tolerance Requirements

Select based on your industry’s straightness and parallelism standards:

Grade 1 (±0.02mm/m):

Ideal for precision machining (e.g., aerospace components, medical device parts) where deviations over 20μm/m cause functional failures. Storaen’s Grade 1 rulers undergo laser interferometry calibration, meeting ISO 1101 and ASME B89.5.2 for traceable accuracy.

Grade 2 (±0.05mm/m):

Suits general industrial tasks like textile loom thread path setup or heavy equipment track alignment, balancing cost ($499 for 2000mm) and performance to reduce fabric defects or machinery vibration.

Grade 3 (±0.1mm/m):

Best for layout marking and rough alignment in construction or prototyping, where absolute precision is less critical but durability (anodized aluminum coating) and value matter most.

3. Material & Cost: Balance Rigidity, Weight, and Budget

Magnesium Aluminum Alloy:

30% lighter than steel, with 110kg/mm² yield strength for anti-deformation—perfect for aluminum rulers needing to withstand heavy loads without bending. Priced 20% higher than steel but offering 3x lifespan, ideal for high-stakes parallel ruler use.

Carbon Steel:

Heavy-duty and budget-friendly ($350 for 1000mm), suitable for occasional use or non-critical alignment in harsh workshops, though heavier (4kg for 1000mm) and prone to rust without regular maintenance.

4. Storaen’s Expert Recommendations

For CNC Machining: Pair a 2000mm magnesium aluminum parallel ruler (Grade 1, $899) with our laser alignment kit for ±0.01mm/m accuracy, minimizing tool wear and scrap rates.

For Textile Industry: A 1500mm anodized aluminum ruler (Grade 2, $599) ensures consistent thread path alignment, backed by a 1-year warranty against coating failure.

Custom Solutions: Need a 5000mm ruler with metric/imperial dual scales? Our team delivers bespoke designs in 4–6 weeks, optimizing for your unique parallel ruler use cases.

Choosing the right parallel ruler doesn’t have to be complex—prioritize size for your workpiece, precision for your tolerance needs, and material for your environment, then trust Storaen’s engineered solutions to deliver reliability at competitive parallel ruler price points. Explore our parallel rulers for sale today, and equip your workshop with tools designed to measure up to the toughest industrial challenges.

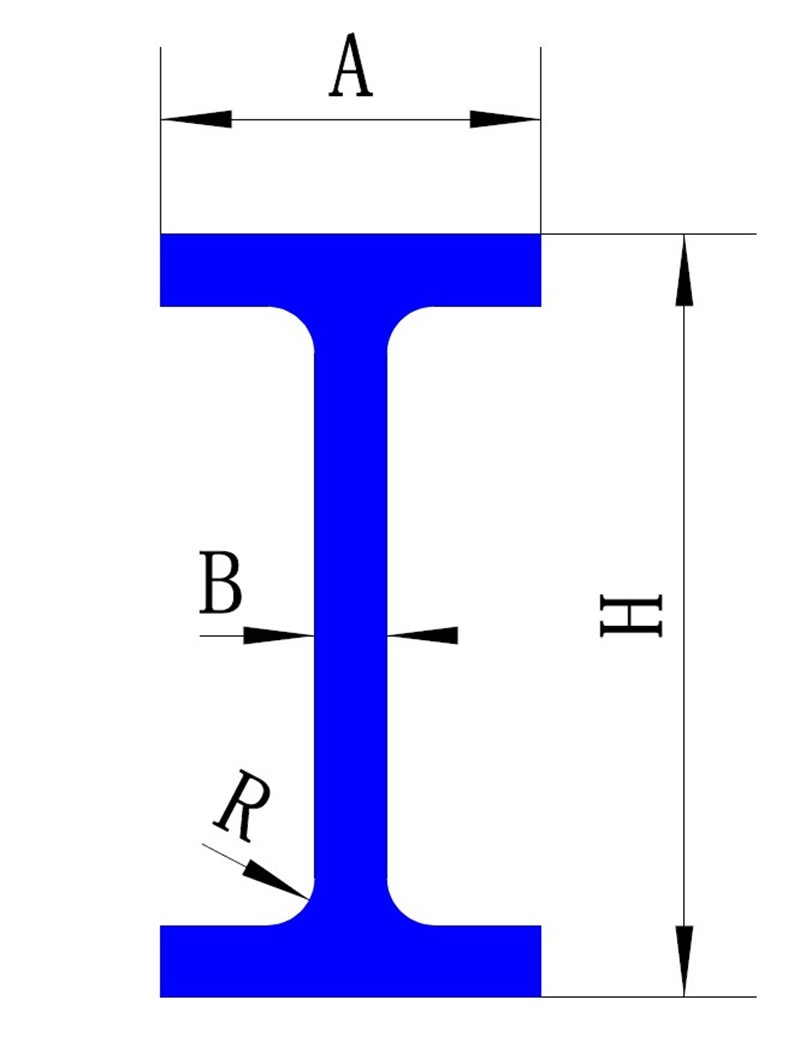

제품 세부 도면

공급업체의 제품 설명

알루미늄 마그네슘 합금 정밀 눈금자:

알루미늄 마그네슘 합금 평행 눈금자는 공작물 검사, 측정, 마킹, 장비 설치 및 산업 건설 프로젝트에 사용됩니다.

* 간편한 보관: 걸거나 수평으로 배치할 수 있으며 단독 배치로 인해 직진성과 평행도에 영향을 미치지 않습니다.

* 녹슬지 않음 : 사용 중에는 기름칠을 하지 마시고, 장기간 사용하지 않을 경우에는 산업용유를 얇게 도포하여 보관하십시오.

* 포장: 합판 상자가 일반적으로 사용됩니다. 정밀한 포장도 가능합니다.

알루미늄 마그네슘 합금의 기술 사양

정밀 눈금자:

|

규격(mm) |

L |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

3500 |

4000 |

|

H |

60 |

60 |

100 |

100 |

150 |

150 |

150 |

150 |

|

|

A |

30 |

30 |

40 |

40 |

80 |

80 |

80 |

80 |

|

|

B |

6 |

6 |

6 |

8 |

8 |

8 |

8 |

10 |

|

|

R |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

8 |

|

|

정밀등급 |

1 |

1 |

1 |

1 |

2 |

2 |

3 |

3 |

|

|

직선(mm) |

0.006 |

0.01 |

0.015 |

0.018 |

0.044 |

0.048 |

0.112 |

0.128 |

|

|

평행도(mm) |

0.008 |

0.016 |

0.022 |

0.027 |

0.066 |

0.072 |

0.168 |

0.26 |

|

|

체중(kg) |

0.8 |

1.5 |

4.5 |

6 |

17.5 |

21 |

24.5 |

28 |

|

관련된 제품

관련 뉴스

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.