제품 설명

- 1.신청

광학 합성 이미지 레벨은 평평한 표면과 원통형 표면의 수평 방향 기울기를 측정하는 데 널리 사용됩니다. 공작기계나 광학기계 기기의 활주로나 베이스의 평면도, 직진도, 장비 설치 위치의 정확성.

- 2. 기술 데이터

(1) 각 눈금값: ...0.01mm/m

(2) 최대 측정 범위: ...0~10mm/m

(3) 공차: ...1mm/1미터 이내... 0.01mm/m

전체 측정 범위 내에서...0.02mm/m

(4) 작업 표면의 평면 편차...0.0003mm/m

(5) 정신 수준의 각 눈금 값...0.1mm/m

(6) 작업면(LW):...165 48mm

(7) 장비의 순중량: ...2kgs.

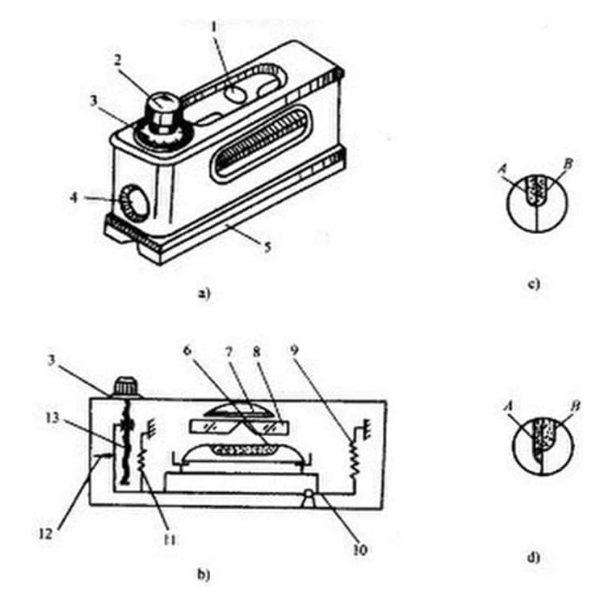

- 3. 악기의 구조:

복합 이미지 수준기는 주로 마이크로 조정 나사, 너트, 눈금 디스크, 기포 수준기, 프리즘, 돋보기, 레버 및 일반 및 V 작업 표면이 있는 베이스와 같은 부품으로 구성됩니다.

- 4.작동 원리:

복합이미지 수준기는 프리즘을 이용하여 기포이미지를 기포수준기 복합이미지로 획득하고 확대하여 판독 정확도를 높이고, 레버 및 마이크로스크류 전달방식을 사용하여 판독 감성을 향상시켰습니다. 따라서 경사도가 0.01mm/m인 작업물이라면 합성 이미지 레벨에서 정확하게 판독할 수 있습니다(합성 이미지 레벨의 스피릿 레벨은 주로 0을 나타내는 역할을 합니다).

- 5. 운영 방법:

측정 작업물의 작업 표면에 합성 이미지 레벨을 배치하면 측정 작업물의 기울기로 인해 견인 기포 이미지가 일치하지 않게 됩니다. 견인 기포 이미지가 일치하고 판독값을 즉시 얻을 수 있을 때까지 눈금 디스크를 회전시킵니다. 측정 대상물의 실제 기울기는 다음 공식으로 계산할 수 있습니다.

실제 기울기= 기울기 값 지점 거리 디스크 판독값

Fox 예: 디스크 읽기: 5개 그라데이션; 이 합성 이미지 레벨은 기울기 값과 지지점 거리에 따라 변경되므로 기울기 값은 0.01mm/m이고 지지점 거리는 165mm입니다.

따라서 실제 기울기=165mm 5 0.01/1000=0.00825mm

- 6.운영 공지:

(1) 사용 전 휘발유로 기름먼지를 닦아낸 후 흡수성 거즈로 닦아주세요.

(2) 온도 변화는 기기에 큰 영향을 미치므로 열원과 분리하여 오류를 방지해야 합니다.

(3) 측정하는 동안 견인 기포 이미지가 완전히 일치할 때까지 눈금 디스크를 회전시킨 다음 양수 방향과 음수 방향의 판독값을 모두 얻을 수 있습니다.

(4) If the instrument is found with in correct zero position, it may be adjusted; Put the instrument on a stable table and rotate the graduated disc to set the tow air bubble images coincide to get first reading a; Then turn the instrument by 180o and put back to its original place. Ra-rotate the graduated disc to get the tow air bubbles coincide to get the second reading b. So 1/2 (α +β ) is the zero deviation of the instrument. Loosen the three supporting screws on the graduated disc and press lightly by hand the embossed adjusting cap; Rotate the disc by 1/2 (α +β) to get the zero deviation and the point line composite; At last fasten the screws.

(5) 작업 후에는 기기의 작업 표면을 청소하고 무산성, 방청유 및 방청지로 코팅해야 합니다. 나무 상자에 넣은 후 깨끗하고 건조한 곳에 보관하세요.

Hot Tags: Optical Composite Image Level Optical Composite Image Level suppliers China Optical Composite Image Level Optical Composite Image Level factory stable Optical Composite Image Level

제품 매개변수

기술적인 매개변수

- 플레이트 값 다이얼 0.01mm/m

- 측정 범위 0-10mm/미터

- Parent-child error within ± 1mm/m+0.01 mm/m

- The parental error within the entire measurement range is ± 0. 02 millimeters/meter

- 벤치 평탄도 편차 0.003mm

- 셀 값 축적 기준 0.1mm/meter

- 사무실 책상 크기 165 x 48mm

- 순중량 2.2kg

Optical Composite Image Level Maintenance: Antirust Oil & Storage Tips

Proper maintenance ensures your optical composite image level retains its 0.01mm/m precision and durability. Follow these steps to protect its prism technology and mechanical components:

1. Daily Cleaning for Surface Protection

After use, wipe working surfaces (V-groove, edges, lenses) with isopropyl alcohol on a lint-free cloth to remove oils and dust. Use a soft brush for stubborn debris—never abrasives, which can scratch optical parts or damage metal coatings. This preserves the precision ground surfaces (Ra ≤ 0.1μm) critical for accurate readings.

2. Routine Antirust Care for Metal Parts

While the granite base resists corrosion, metal components (screws, levers, hinges) need protection. Apply Storaen’s non-acidic anti-rust oil every 3 months or after moisture exposure:

Apply thinly to threads and pivots with a dropper, avoiding pooling on granite/lenses.

Prevents seizing: Maintains lever mechanism sensitivity (0.001mm precision) for cylindrical slope measurements.

3. Optimal Storage Practices

Store in the included hard case or a dry cabinet to avoid temperature/humidity damage:

Environment: 10°C–30°C, <60% humidity to prevent lens condensation and optical distortion.

Positioning: Lay flat or upright in padded slots; never under heavy objects to avoid misaligning the optical system.

Long-term storage: Reapply anti-rust oil and add a silica packet; inspect 24 hours before use, verifying zero position via 180° rotation calibration.

4. Monthly Functional Inspections

Check performance regularly to ensure reliability:

Bubble clarity: Confirm the composite bubble image aligns smoothly without blur.

Lever movement: Test micro-screws for smooth rotation—stiffness signals needed lubrication.

Flatness check: Use a reference plate to validate factory-calibrated flatness (±0.0003mm/m).

5. Storaen’s Support for Longevity

Leverage our expert services to maintain peak performance:

Factory recalibration: Restores 0.01mm/m precision via ISO-certified equipment for critical applications.

Genuine parts: Replacement components ensure compatibility and preserve original accuracy.

By following these steps, your Storaen optical composite image level will deliver consistent precision for industrial alignment tasks, backed by our 30+ years of engineering expertise.

Zero Position Calibration of Optical Composite Image Level: 180° Rotation Method Explained

Accurate zero calibration is vital for your Storaen optical composite image level to maintain its 0.01mm/m precision and ±0.0003mm/m flatness. The 180° rotation method eliminates subtle optical or mechanical shifts, ensuring reliable measurements in critical tasks like CNC machine alignment or aerospace component inspection. Here’s a streamlined, step-by-step guide:

1. Why Calibrate?

Impacts, vibrations, or temperature fluctuations can shift the level’s zero reference, leading to measurement drift. Calibration realigns the bubble vial with the tool’s optical prism and lever system, ensuring consistent baselines for industrial applications where 0.001mm deviations are unacceptable—such as verifying machine tool guides or structural frameworks.

2. Setup Requirements

Storaen optical composite image level (featuring a V-grooved base and micro-adjusting screw)

Certified precision reference flat (e.g., our Storaen granite surface plate, with flatness ≤0.0002mm/m)

A clean, vibration-free workbench in a temperature-stabilized environment (18°C–22°C recommended)

3. Step 1: Initial Measurement

Place the level lengthwise on the reference flat, aligning the V-grooved base with the flat’s central axis. Rotate the micro-adjusting screw until the composite bubble image—created by the 45° prism system—perfectly overlaps in the viewfinder. Record this initial scale reading (A), which reflects the current deviation from true zero.

4. Step 2: 180° Rotation & Second Reading

Carefully flip the level 180° end-to-end while maintaining its longitudinal orientation on the flat (avoid any lateral movement). Adjust the micro-screw again to align the bubble image and record the new reading (B). The difference Δ = |A - B| indicates zero position error; ideal values for Storaen levels should be ≤0.005mm/m.

5. Step 3: Error Correction & Verification

Calculate the target zero position as the midpoint: C = (A + B)/2. Loosen the protective cap on the zero-adjustment screw (typically located near the bubble vial), rotate the screw until the scale reads C, then retighten. Repeat Steps 3–4 until Δ ≤0.002mm/m, ensuring minimal residual error.

6. Pro Tips for Precision

Triple-Check Consistency: Perform 3 calibration cycles, especially after transporting the level or working in environments with temperature swings, to ensure repeatable results.

Lubricate Moving Parts: Apply a drop of Storaen’s non-acidic oil to the micro-screw before adjustment to ensure smooth, backlash-free operation and prevent binding.

Environmental Control: Avoid calibrating near heat sources or drafts, as even minor temperature gradients can affect the granite base’s dimensional stability and introduce errors.

7. Storaen’s Calibration Support

Every Storaen optical composite image level includes a NIST-traceable calibration certificate, but quarterly in-field checks are recommended for heavy use. Our support includes:

Factory Recalibration: Restoring original 0.01mm/m accuracy using laser interferometers for high-stakes applications.

Genuine Spare Parts: Readily available adjustment screws and maintenance kits for long-term usability.

Video Tutorials & Expert Guidance: Step-by-step videos and engineer support to assist with on-site calibration procedures.

Final Notes

Mastering the 180° rotation method ensures your Storaen optical composite image level delivers the precision required for cylindrical slope measurements, machine tool flatness checks, and other critical alignments. With proper calibration, this tool, backed by our 30+ years of engineering expertise, becomes an indispensable asset in your quality control workflow, ensuring every measurement is as reliable as the first.

관련된 제품

관련 뉴스

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.