10월 . 15, 2024 07:06 Back to list

tilting disc check valve

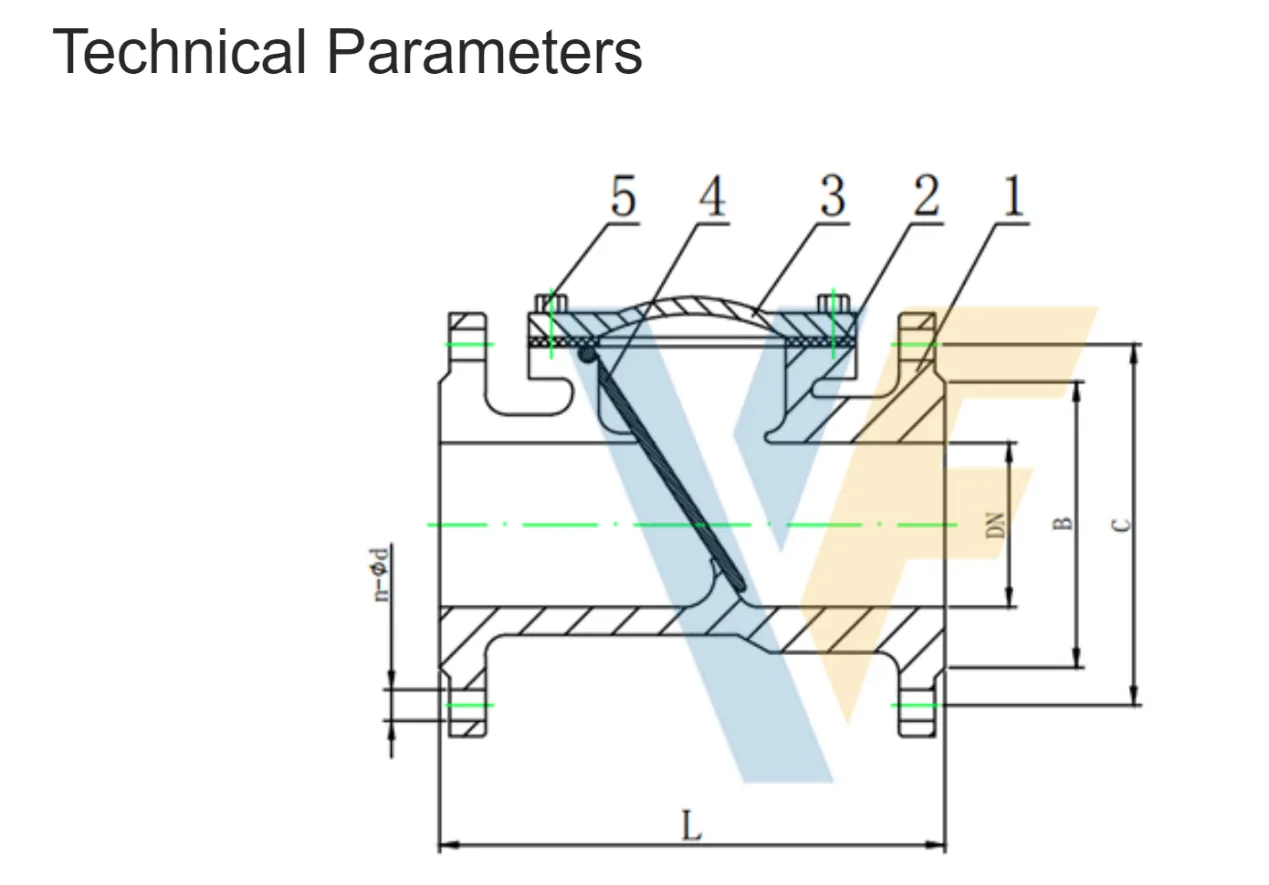

Understanding Tilting Disc Check Valves

Tilting disc check valves are essential components in various fluid systems, primarily used to prevent backflow while allowing forward flow. These valves are designed to open and close based on the flow of fluid, ensuring operational efficiency and system safety. This article will provide an overview of the tilting disc check valve's design, functioning, applications, and advantages.

Design and Functioning

The tilting disc check valve features a unique design that distinguishes it from conventional swing check valves. It consists of a circular disc that pivots around a hinge point. This disc is held in a tilted position during forward flow, allowing fluids to pass through with minimal resistance. When the flow reverses, the disc tilts against the seat of the valve, creating a seal that prevents backflow.

The valve’s design allows for a quick response to changes in flow direction. The tilting action of the disc reduces the risk of water hammer, a common issue that can damage piping systems. Additionally, the disc can be made from various materials such as stainless steel, bronze, or plastic, depending on the application and fluid characteristics.

Applications

Tilting disc check valves are used in a wide range of applications across various industries. One of the primary uses is in water and wastewater treatment facilities, where they help control the flow of sewage and treated water. They are also commonly found in power plants, chemical processing, food and beverage manufacturing, and HVAC systems.

tilting disc check valve

In power plants, for example, tilting disc check valves are crucial for maintaining the integrity of water supply systems. They prevent backflow that could potentially damage pumps and other equipment. In HVAC systems, these valves ensure that water circulates correctly through heating and cooling loops, enhancing system efficiency.

Advantages

The use of tilting disc check valves offers several advantages. Firstly, their design allows for low pressure loss during forward flow, which is essential for energy efficiency in fluid systems. The rapid response to flow changes minimizes the risk of water hammer, protecting both the valve and the connected piping.

Moreover, the tilting disc design enables these valves to operate effectively at various angles, making them versatile for installation in a range of orientations. This flexibility is beneficial in tight spaces where conventional valves might not fit. Additionally, the ability to construct the disc from corrosion-resistant materials extends the lifespan of the valve and reduces maintenance costs.

Conclusion

Tilting disc check valves play a vital role in the safe and efficient operation of various fluid systems. Their innovative design allows for effective backflow prevention with minimal pressure loss, making them ideal for a multitude of applications across different industries. As technology progresses and the demand for efficient fluid management systems increases, tilting disc check valves will continue to be indispensable tools in ensuring operational integrity and system reliability. Understanding their functionality and benefits helps industries optimize their processes while maintaining safety and compliance.

-

Types of Thread Gauge BSP Parallel DesignNewsAug.04,2025

-

Ring Gauge Cylindrical Check ApplicationNewsAug.04,2025

-

Machinist Gauge Pins GCr15 MaterialNewsAug.04,2025

-

Gate Valves for Sale Sewage System UseNewsAug.04,2025

-

Control Valve EPDM Seal MaterialNewsAug.04,2025

-

Cast Iron Y Type Strainer Flange Cover DesignNewsAug.04,2025

Related PRODUCTS