11월 . 09, 2024 20:19 Back to list

Exploring the Features and Benefits of 10% Globe Valve for Fluid Control

Understanding the 10% Globe Valve Features, Applications, and Benefits

Globe valves are a crucial component in many industrial applications, serving primarily as a throttling device to control the flow of fluids. Among the various types of globe valves, the 10% globe valve is notable for its unique design and applications. This article explores the features, uses, and advantages of the 10% globe valve, highlighting its significance in various systems.

What is a 10% Globe Valve?

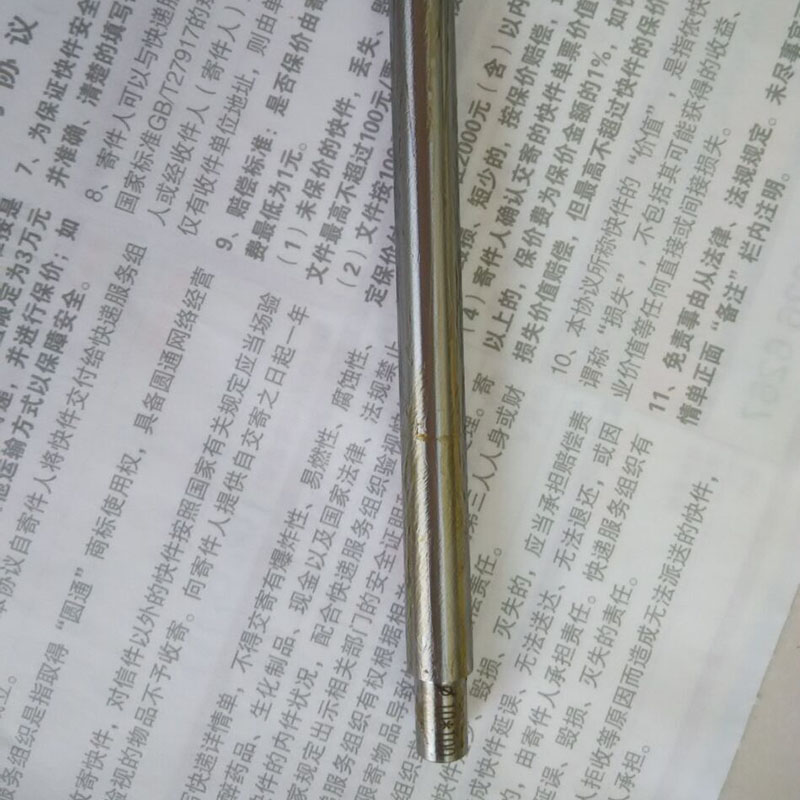

A 10% globe valve is designed to regulate fluid flow by utilizing a spherical body and a movable disk mechanism. The term 10% refers to the valve's ability to provide a flow rate variation, which can be adjusted to approximately 10% of the maximum capacity. This type of valve is particularly effective in situations where precise control over the flow is required, making it an ideal choice in many engineering applications.

Key Features

1. Flow Control The primary feature of the 10% globe valve is its capability to finely control fluid flow. The design allows for a gradual change in flow, thus minimizing the risks of cavitation and hydraulic shock, which can occur in other types of valves.

2. Spherical Body The spherical shape of the globe valve allows for better flow distribution and pressure drop management. This design aids in maintaining system efficiency, particularly in high-pressure applications.

3. Versatility 10% globe valves can be made from various materials, including brass, stainless steel, and carbon steel, making them suitable for different fluids, including water, oil, and gas.

4. Durability These valves are generally robust and can withstand harsh conditions, contributing to their long lifespan. Their construction minimizes wear and tear, which reduces the frequency of maintenance and replacement.

Applications

10 globe valve

The 10% globe valve finds applications across several industries

- Water Supply Systems These valves help regulate water flow in municipal systems, ensuring the steady supply of water to households and businesses. - Oil and Gas Industry They are commonly used in pipelines for controlling the flow of crude oil and natural gas, accommodating the industry's need for precise flow regulation. - Chemical Processing The 10% globe valve is essential in chemical plants where accurate control over the flow of various chemical substances is critical for safety and efficiency. - HVAC Systems In heating, ventilation, and air conditioning systems, these valves help maintain appropriate flow rates, enhancing energy efficiency and comfort.

Benefits of Using a 10% Globe Valve

1. Precise Flow Regulation The ability to adjust flow finely makes the 10% globe valve an excellent choice for applications demanding accurate control.

2. Reduced Energy Costs By maintaining optimal flow conditions, these valves contribute to energy efficiency, ultimately lowering operational costs.

3. Long-Term Reliability The durable construction of 10% globe valves ensures that they can perform effectively over long periods, minimizing downtime and maintenance costs.

4. Safety By preventing sudden changes in pressure and flow, these valves help maintain system integrity and enhance overall safety.

Conclusion

The 10% globe valve serves as a vital component in many industries, offering unmatched control over fluid dynamics. Its features, such as flow regulation and durability, make it an asset in applications ranging from water supply systems to oil and gas pipelines. As industries continually seek efficiencies and safety, the role of the 10% globe valve will undoubtedly remain significant in the years to come. By understanding its applications and benefits, engineers and system designers can better leverage this essential tool in their operations.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS