ធ្នូ . 16, 2024 05:13 Back to list

Magnetic Vee Block for Precision Machining and Workholding Applications

The Versatility and Importance of Magnetic Vee Blocks in Precision Engineering

In the realm of precision engineering and metalworking, the significance of accurate measurements, secure workholding, and efficient setups cannot be overstated. Among the myriad tools designed to enhance productivity and precision, the magnetic vee block stands out as a highly versatile instrument. This specialized tool is invaluable for machinists and engineers who require stable and reliable support for various workpieces.

What is a Magnetic Vee Block?

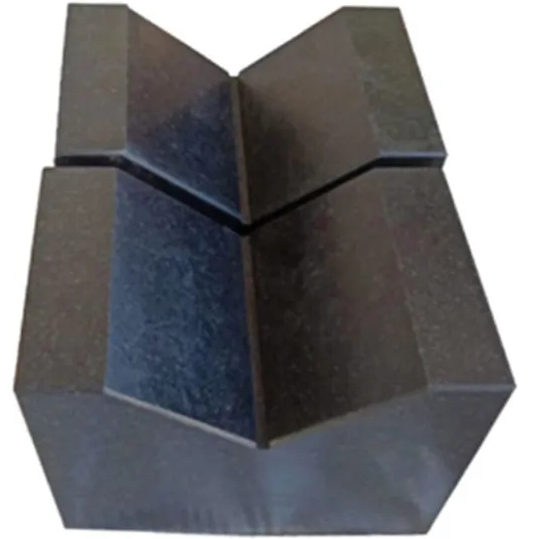

A magnetic vee block is essentially a rectangular block of metal with a V-shaped groove along its length. Its primary purpose is to hold cylindrical objects firmly in place, making it easier to work on them, whether that be cutting, grinding, or measuring. The magnetic feature of this block allows it to adhere firmly to ferromagnetic surfaces, ensuring that the workpiece remains stationary during operation.

Key Features and Benefits

1. Enhanced Stability The V-shaped groove provides a stable base for cylindrical and round workpieces. This design ensures that the object is held securely, minimizing movement during machining processes. The magnetic base adds an extra layer of stability, significantly reducing vibrations that could lead to inaccuracies.

2. Versatile Applications Magnetic vee blocks are incredibly versatile. They are used in various applications, including cylindrical grinding, inspection processes, and aligning components before welding or machining. Their adaptability makes them an essential tool in both basic machining tasks and complex engineering projects.

magnetic vee block

3. Ease of Use Setting up a workpiece with a magnetic vee block is straightforward. The user can easily position the block on a magnetic table or surface and use the magnet to lock it in place. This simplicity allows for quick adjustments and repositioning, thereby saving time in the workshop.

4. Increased Accuracy Precision is paramount in engineering, and using a magnetic vee block can increase the accuracy of measurements and cuts. The stable positioning provided by the block minimizes the risk of errors and ensures that workpieces are machined to exact specifications.

5. Durable Construction Typically made from high-quality steel, magnetic vee blocks are designed to withstand the rigors of machining environments. They are resistant to wear and tear, which prolongs their lifespan and enhances their reliability.

Conclusion

As the demands for precision in manufacturing continue to rise, tools like magnetic vee blocks are becoming increasingly important. Their ability to secure and stabilize parts during machining processes enhances productivity and accuracy, making them indispensable in workshops and manufacturing facilities worldwide.

In conclusion, whether you're a seasoned machinist or a novice engineer, incorporating a magnetic vee block into your toolkit can elevate your work. Its blend of stability, versatility, and ease of use makes it a fundamental asset in the pursuit of precision in engineering and metalworking. As technology and methodologies evolve, tools like these will continue to play a crucial role in shaping the future of manufacturing, ensuring that high standards of precision and quality are met consistently.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS