វិច្ឆិកា . 18, 2024 06:12 Back to list

12 Inch Globe Valve Specifications and Applications for Industrial Use

Understanding the Globe Valve A 12-Inch Perspective

Valves play a crucial role in various industrial applications, regulating the flow of fluids within pipelines. Among these, the globe valve is one of the most important and versatile types, particularly when it comes to precision flow control. Focusing on the 12-inch globe valve, we will explore its structure, functionality, applications, and advantages.

Structure and Functionality

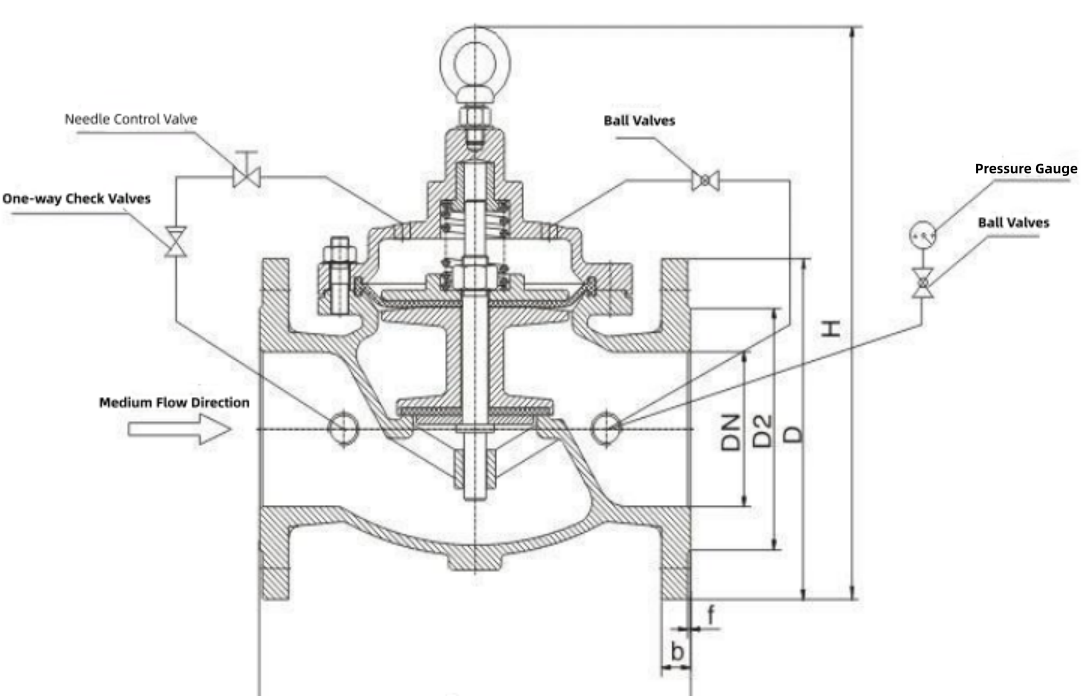

Globe valves are named for their spherical body shape. The interior design of a globe valve consists of a movable disk or plug element that serves to obstruct or allow flow through the valve. When the handle or actuator is turned, the disk rises or falls against a seat, permitting controlled flow rates. Specifically, a 12-inch globe valve refers to its nominal size – indicating a port diameter of 12 inches.

This size is significant in industries that require the transport of large volumes of liquid or gas. The larger diameter allows for significant flow capacity while maintaining precision control over the flow rate. Globe valves are typically made from durable materials such as cast iron, stainless steel, or bronze, ensuring their longevity and reliability under high pressure and temperature conditions.

Operating Principles

The design of a globe valve allows it to provide better throttling capabilities compared to other valve types, such as gate or ball valves. This is achieved due to the favorable flow path configuration, which creates less turbulence. When fully open, a globe valve allows for an unrestricted flow of the media. However, it is when the valve is partially opened that the throttling feature becomes evident, enabling fine adjustments to the flow rate.

For a 12-inch globe valve, the valve may be operated manually with a wheel or lever, or automatically using electric or pneumatic actuators. The choice of operation depends on system requirements and the specific application of the valve.

Applications

globe valve 12 inch

12-inch globe valves are commonly used in a variety of sectors including water treatment, oil and gas, power generation, and chemical processing. In water treatment plants, for instance, they help manage the flow of treated water and control the distribution of chemicals used in the purification process. Within oil and gas operations, they are vital for regulating crude oil, natural gas, and other hydrocarbons during extraction, transportation, and refinement.

Additionally, power plants utilize globe valves to control the flow of steam and water, thereby enhancing operational efficiency and safety. Their ability to provide reliable flow management makes them invaluable in critical applications where precision is required.

Advantages

One of the primary advantages of using a 12-inch globe valve is its ability to control flow effectively. For operations that require fine regulation, such as chemical dosing or steam flow management, globe valves are often preferred.

Moreover, these valves are relatively easy to maintain. Their design allows for inspection of internal components without needing to remove the entire valve from the pipeline, thus minimizing downtime. The robust materials used in their manufacture also contribute to their reliability and ability to withstand harsh operating environments.

Lastly, globe valves are designed to provide a tight seal, which is crucial in preventing leakages. This property not only enhances safety but also reduces operational costs associated with fluid loss.

Conclusion

In summary, the 12-inch globe valve is a key component across various industrial applications due to its effectiveness in flow regulation and durability. Understanding its structure, functionality, and applications is vital for anyone involved in industries reliant on fluid management. By optimizing flow control, globe valves enhance system efficiency, contributing to both productivity and safety in operations. As industries continue to evolve, the significance of reliable components like the 12-inch globe valve will only become more pronounced.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS