វិច្ឆិកា . 04, 2024 11:55 Back to list

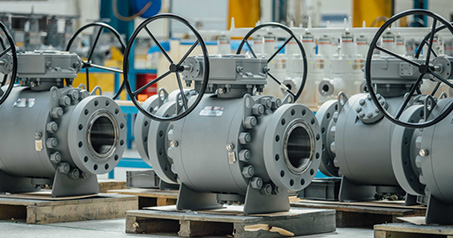

Top Gate Valve Manufacturers and Their Innovative Solutions for Industrial Applications

Understanding Gate Valve Manufacturers A Comprehensive Overview

Gate valves play a crucial role in regulating the flow of fluids in various industrial systems. These valves are renowned for their ability to provide minimal resistance to flow when fully open, making them an ideal choice for applications requiring a straight-line flow of fluid. The design and manufacturing of gate valves involve several technical considerations, and a vast array of manufacturers are dedicated to producing high-quality products for diverse applications. This article explores the key aspects of gate valve manufacturers, including their significance, manufacturing processes, and factors to consider when choosing a supplier.

Importance of Gate Valves

Gate valves are essential in numerous industries, including oil and gas, water treatment, power generation, and petrochemical operations. They are primarily used for on/off control of fluid flow rather than for throttling purposes. When fully open, a gate valve creates a straight path for fluid, which minimizes pressure drop across the valve. Conversely, when closed, the valve tightly seals off the flow, preventing leakage. This unique functionality makes gate valves ideal for applications where complete shut-off is necessary.

Manufacturers The Backbone of the Industry

The global demand for gate valves has given rise to a myriad of manufacturers, each specializing in various types, materials, and sizes of valves. Prominent gate valve manufacturers often invest heavily in research and development to innovate and improve valve design and performance. Major players in the industry are equipped with advanced technologies and skilled personnel to ensure that their products meet stringent quality standards and comply with international regulations.

These manufacturers also focus on specific sectors, tailoring their products to meet the unique needs of industries such as natural gas, sewage treatment, and industrial processes. Brands that have established a strong reputation in the market often emphasize quality assurance, reliability, and after-sales support, which are critical factors for their clients.

Manufacturing Process of Gate Valves

The manufacturing process of gate valves involves several steps, each critical to ensuring product quality and performance. It typically begins with the selection of suitable materials, which may include stainless steel, cast iron, brass, or specialized alloys, depending on the application's requirements. Once the material is selected, it undergoes various processes such as casting, forging, or machining to form the valve body and other components.

After the primary components are produced, they are assembled with other parts, including the gate, seat, stem, and actuator. The assembly process is followed by rigorous testing, which may include hydrostatic testing, leakage tests, and pressure testing to ensure that the valve meets safety and performance specifications.

Finally, the finished products are subjected to quality assurance checks before being packaged and shipped to clients. This thorough process is critical to maintaining the high standards expected in the valve manufacturing industry.

gate valve manufacturers

Factors to Consider When Choosing a Gate Valve Manufacturer

When selecting a gate valve manufacturer, there are several key factors to consider

1. Quality Assurance Look for manufacturers who follow internationally recognized quality management standards (such as ISO 9001) to ensure product reliability.

2. Experience and Reputation Established manufacturers with a solid track record in the industry are more likely to deliver consistent quality and performance.

3. Customization Options Depending on the specific application, you may need customized valves. Check if the manufacturer is willing to provide tailored solutions.

4. After-Sales Support A strong after-sales support system can help address any issues that arise with valve performance, ensuring continued operation and satisfaction.

5. Certifications and Compliance Ensure that the valves meet industry standards and regulatory requirements relevant to your application, such as API, ANSI, or ASME certifications.

6. Technology and Innovation Manufacturers that invest in the latest technologies and continuous improvement are likely to produce more efficient and durable products.

Conclusion

Gate valve manufacturers are vital to numerous industries, ensuring the safe and efficient regulation of fluid flow. With a robust understanding of the manufacturing processes, along with careful consideration of quality, experience, and support, buyers can make informed decisions when selecting a gate valve supplier. As technology continues to evolve, the gate valve market will likely see innovations that enhance valve performance and reliability, further solidifying its importance in industrial applications worldwide.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS